device for clutch assembly

A clutch and workbench technology, which is applied in the field of clutch assembly devices, can solve problems such as the reduction of clutch efficiency, and achieve the effects of increasing the interval, saving adjustment time, and increasing the horizontal distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

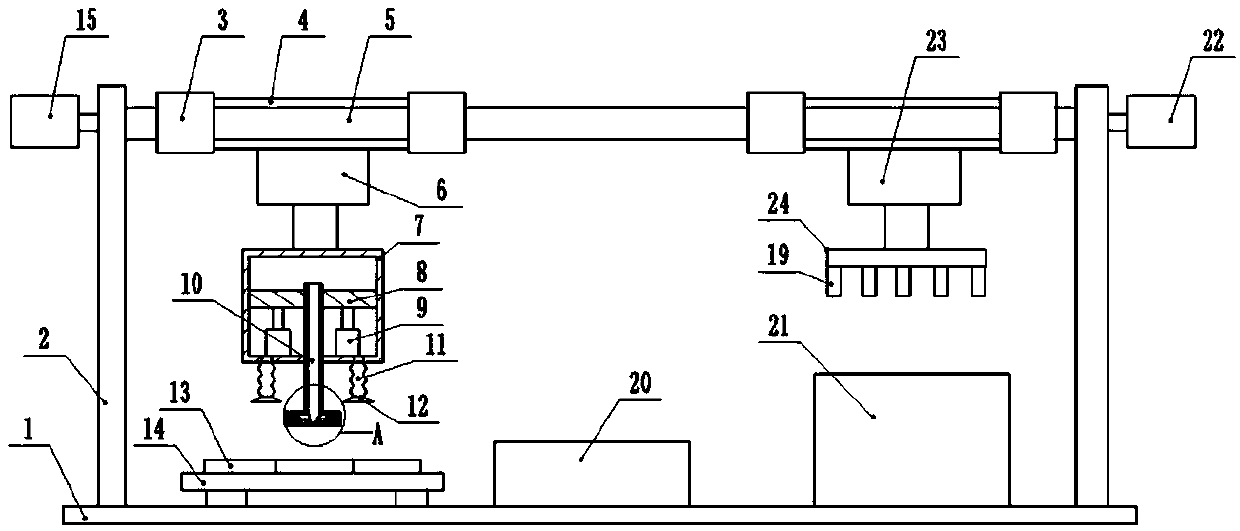

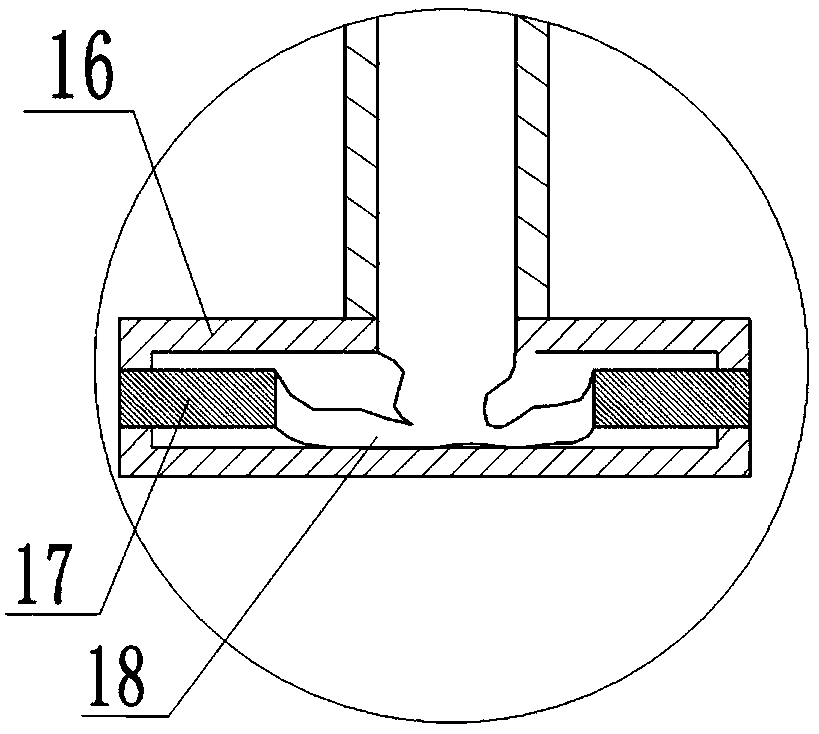

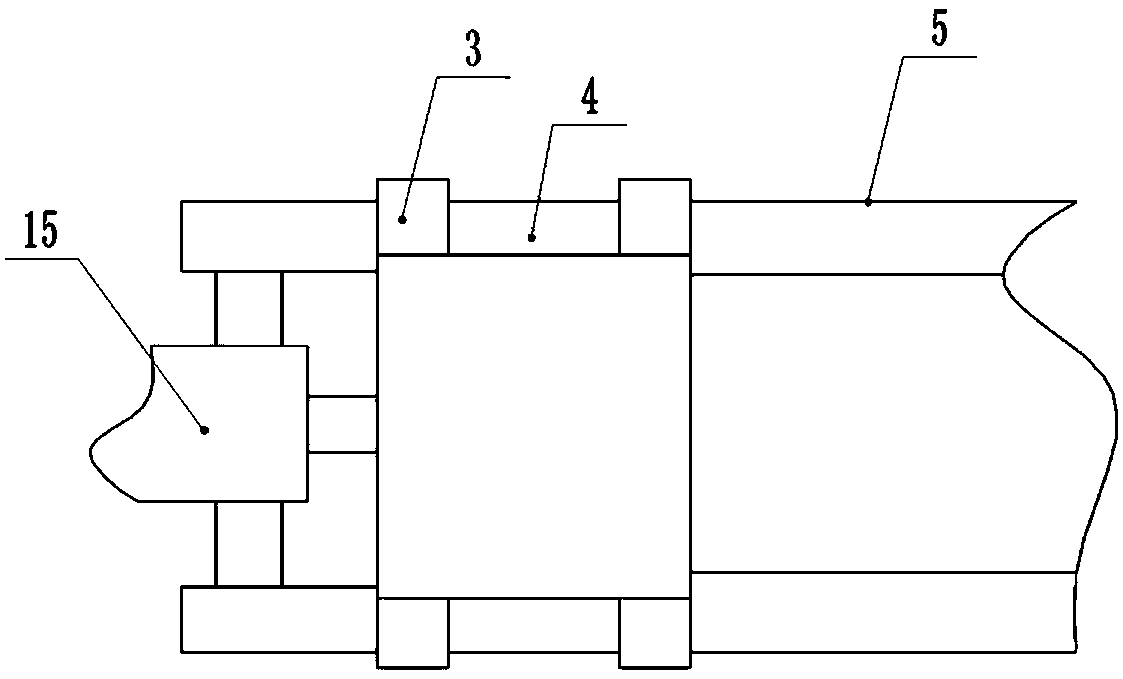

[0026] The reference signs in the drawings of the description include: workbench 1, frame 2, slide seat 3, slide plate 4, slide rail 5, lifting cylinder 6, cylinder body 7, first piston 8, power cylinder 9, central shaft 10, Elastic bellows 11, suction cover 12, corrugated plate 13, positioning plate 14, first hydraulic cylinder 15, clamping plate 16, slider 17, air bag 18, suction cup 19, assembly table 20, rivet placement table 21, second Hydraulic cylinder 22, first cylinder 23, fixed plate 24, self-locking switch 25, electromagnet 26, baffle plate 27, spring 28, ring support 29, second cylinder 30, support rod 31.

[0027] Such as figure 1 As shown, the device for clutch assembly includes a workbench 1, on which a frame 2 is installed, two parallel slide rails 5 are installed on the upper end of the frame 2, an assembly platform 20 is installed in the middle of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com