Aroma essential oil and preparing method and application thereof

An essential oil and fragrance technology, applied in the field of aromatic essential oils and its preparation, can solve the problems of long decomposition time, human hazards, and easy volatility, and achieve the effects of easy storage, air purification, and odor elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

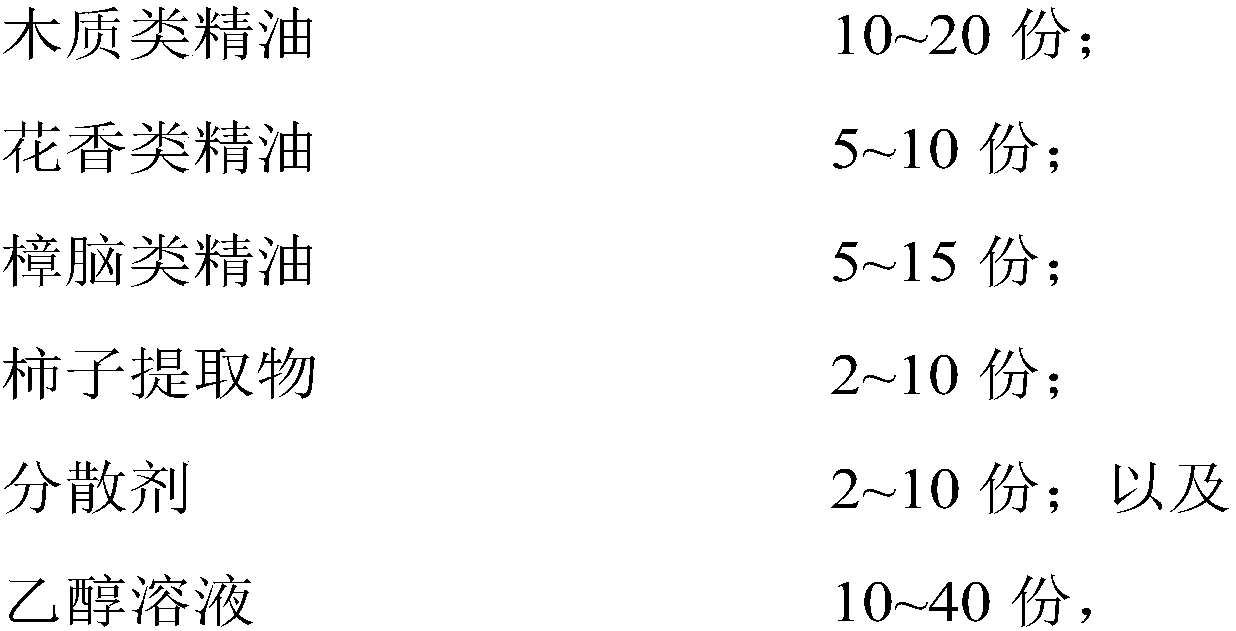

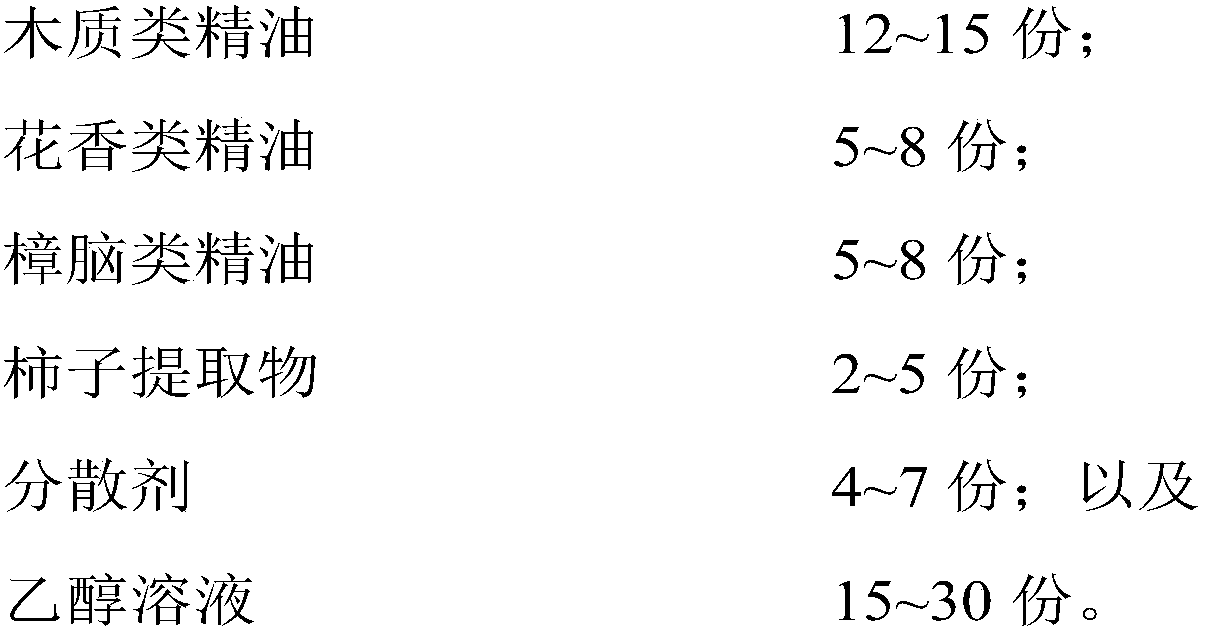

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment provides a kind of fragrant essential oil, and it is to make according to the following process:

[0033] Prepare raw materials: 15 parts of woody essential oils (formed by camphor oil, eucalyptus oil, and cedar oil in a volume ratio of 1:1:1); 6 parts of floral essential oils (made of cherry blossom essential oil, ylang-ylang essential oil, and lily 1:1:1 ratio); 8 parts of camphor-like essential oil (formed by volume ratio 1:1:1 ratio of green bamboo essential oil, green tea essential oil, and peppermint essential oil); 5 parts of persimmon extract; 5 parts of dispersant; and 30 parts ethanol solution.

[0034] First add dispersant to the ethanol solution and mix evenly by ultrasonic vibration, then add persimmon extract, and mix uniformly by ultrasonic vibration; then add woody essential oil, floral essential oil and camphor essential oil, and mix uniformly by ultrasonic vibration to obtain the fragrant essential oil.

Embodiment 2

[0036] The present embodiment provides a kind of fragrant essential oil, and it is to make according to the following process:

[0037] Preparation materials: 10 parts of woody essential oils (formed by volume ratio 1:1:1 of cedar wood oil, sandalwood essential oil, pine essential oil); 5 parts of floral essential oils (formed by volume ratio of lily essential oil, lavender essential oil, rose essential oil 1:1:1 ratio); 5 parts of camphor essential oil (formed from peppermint essential oil, rosemary essential oil, and Melaleuca essential oil in a volume ratio of 1:1:1); 3 parts of persimmon extract; 5 parts dispersant; and 20 parts ethanol solution.

[0038] First add dispersant to the ethanol solution and mix evenly by ultrasonic vibration, then add persimmon extract, and mix uniformly by ultrasonic vibration; then add woody essential oil, floral essential oil and camphor essential oil, and mix uniformly by ultrasonic vibration to obtain the fragrant essential oil.

Embodiment 3

[0040] The present embodiment provides a kind of fragrant essential oil, and it is to make according to the following process:

[0041] Preparation materials: 13 parts of woody essential oils (formed by eucalyptus oil, cedarwood oil, and sandalwood essential oil in a volume ratio of 1:1:1); 6 parts of floral essential oils (formed by volume ratio 1:1:1 ratio); 7 parts of camphor essential oil (formed by green tea essential oil, peppermint essential oil, and rosemary essential oil in a volume ratio of 1:1:1); 3 parts of wintergreen essential oil; 3 parts of persimmon extract; 6 parts dispersant; and 22 parts ethanol solution.

[0042] First add dispersant to the ethanol solution and mix evenly with ultrasonic vibration, then add persimmon extract, and mix uniformly with ultrasonic vibration; then add woody essential oils, floral essential oils, camphor essential oils, wintergreen essential oil, and mix uniformly with ultrasonic vibration to obtain Fragrant essential oils.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com