Ball joint for a vehicle with a tilt angle measuring device

A technology of ball joints and inclination angles, which is applied in the directions of pivot connection, bearing assembly, shaft and bearing, etc., which can solve the problems of high processing cost of joint balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

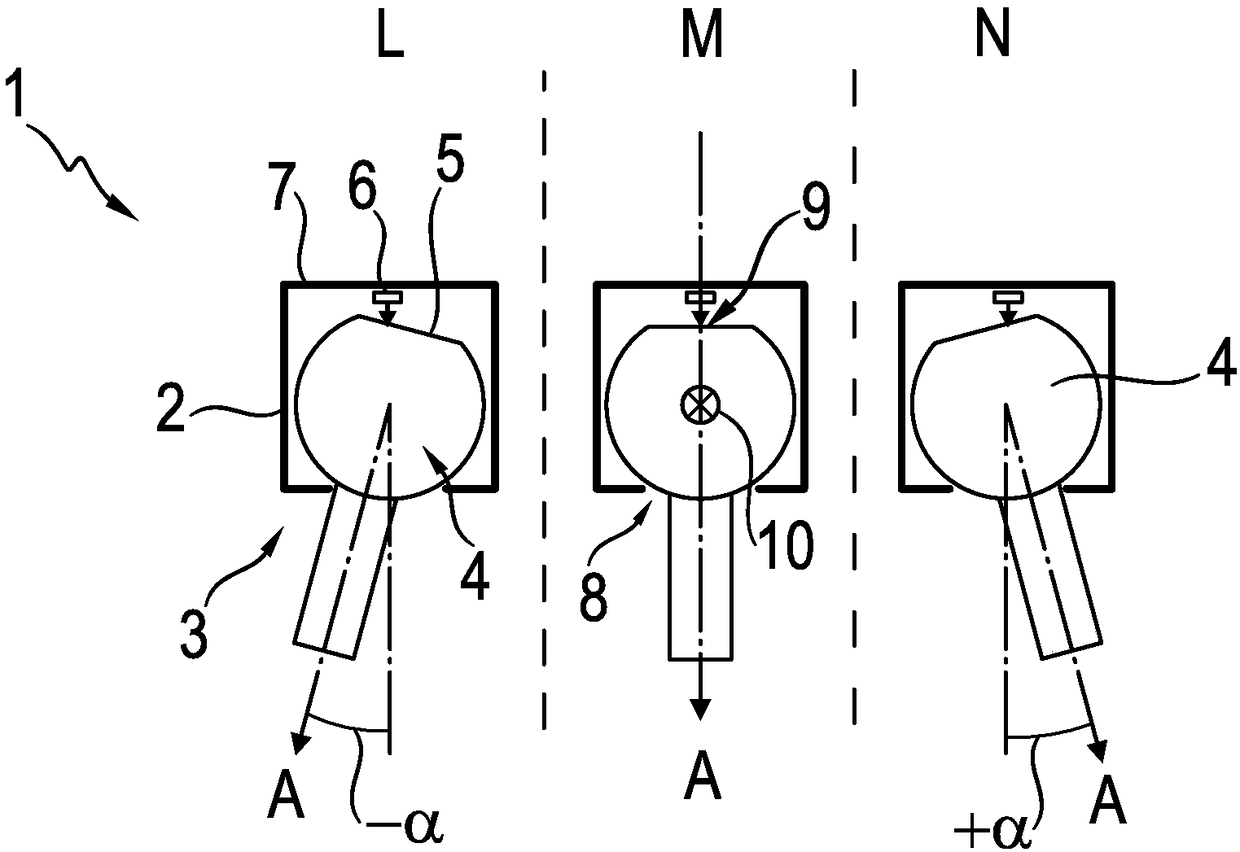

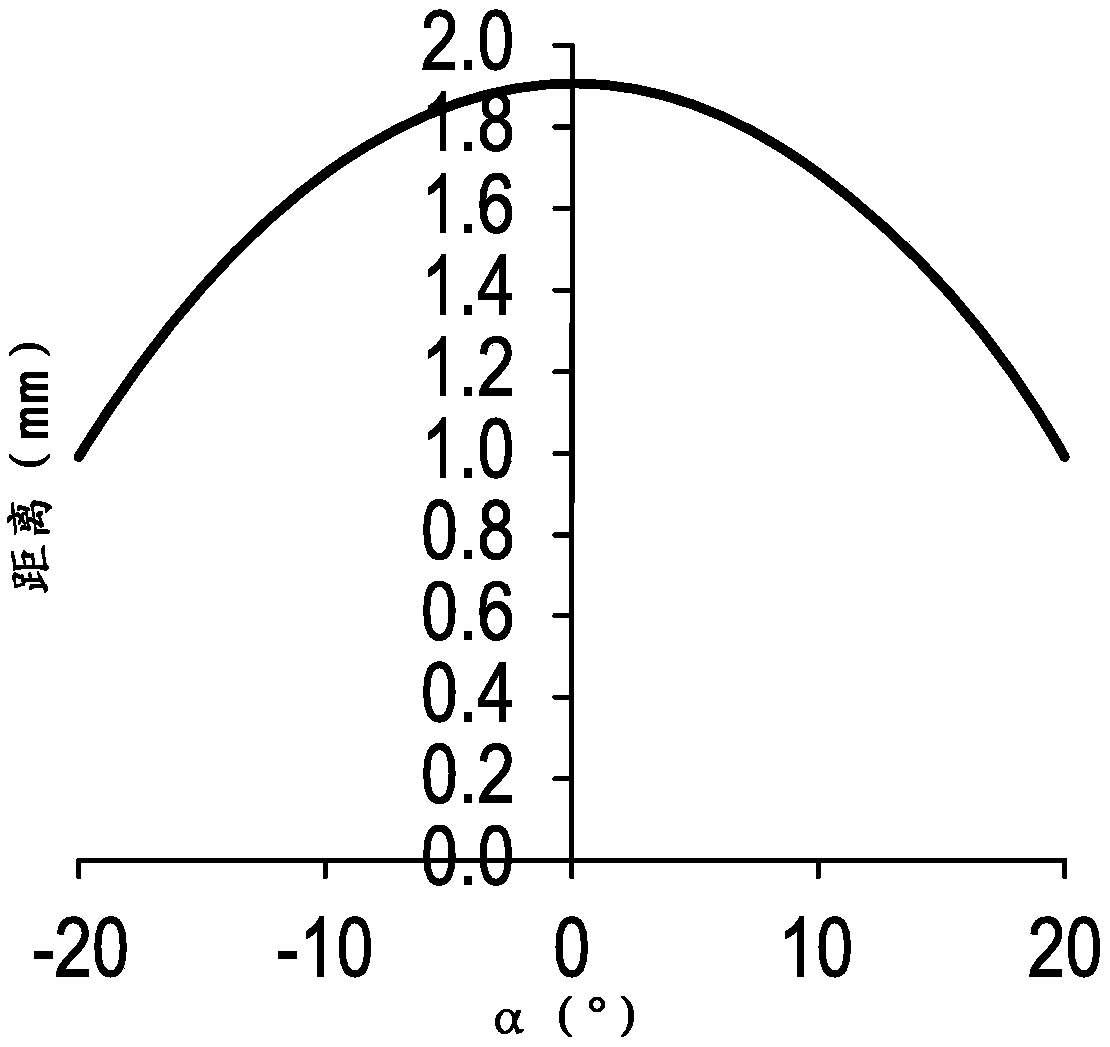

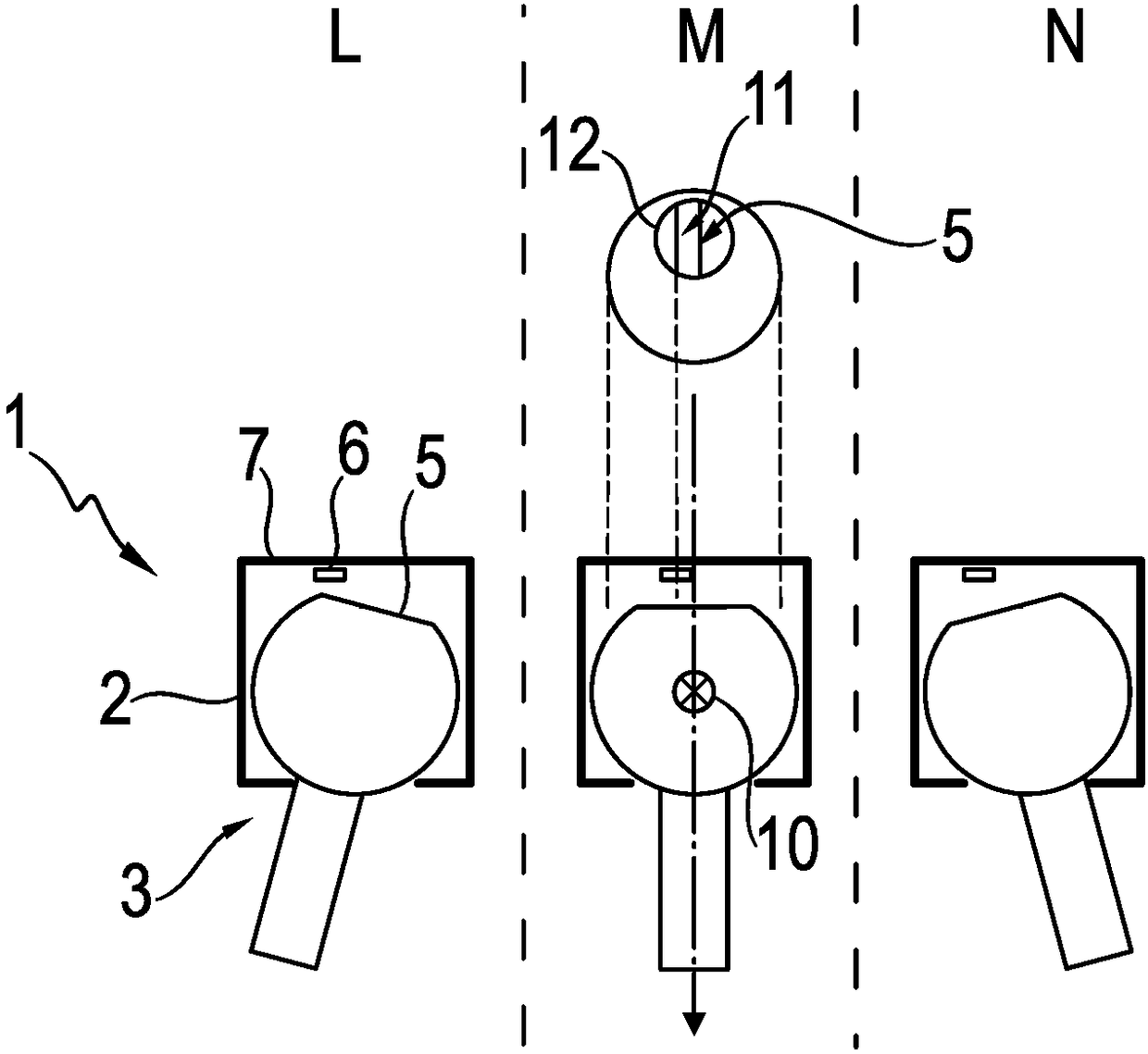

[0026] Figure 1aA ball joint 1 with a housing 2 and a ball pin 3 is shown. The ball pin 3 has a ball joint 4 , wherein the ball joint 4 has a flattened area 5 . Opposite this flattened area 5 , the sensor 6 is arranged on the housing wall 7 . Sensor 6 is a distance sensor. The ball pin 3 also extends out of the housing 2 in the axial direction A through the opening 8 . The ball joint 1 is shown in three different positions L, M, N. In the first position L, there is a negative inclination angle −α between the ball pin 3 and the housing 2 . In the second position M there is an angle of inclination α between the ball pin 3 and the housing 2 of 0 degrees, and in the third position N there is a positive angle of inclination +α between the ball pin 3 and the housing 2 . The axial direction A of the ball pin 3 is indicated by a straight line A in each case. If the inclination angle α between the ball pin 3 and the housing 2 is 0 degrees, as in Figure 1a As shown in the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com