Method for controlling a valve and corresponding valve apparatus

A technology for controlling valve and valve position, applied in valve device, valve operation/release device, fluid pressure actuating device, etc., can solve the problems of mechanical failure downtime, hidden safety hazards, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

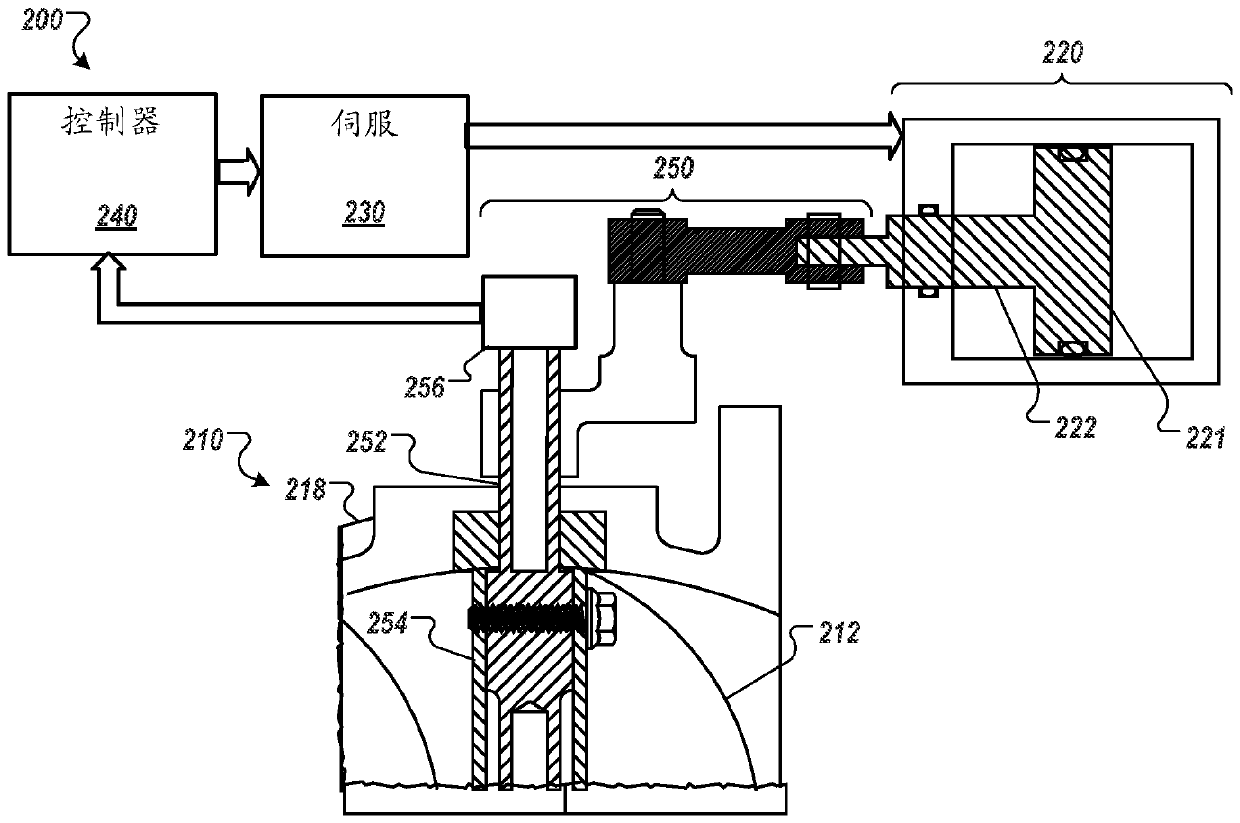

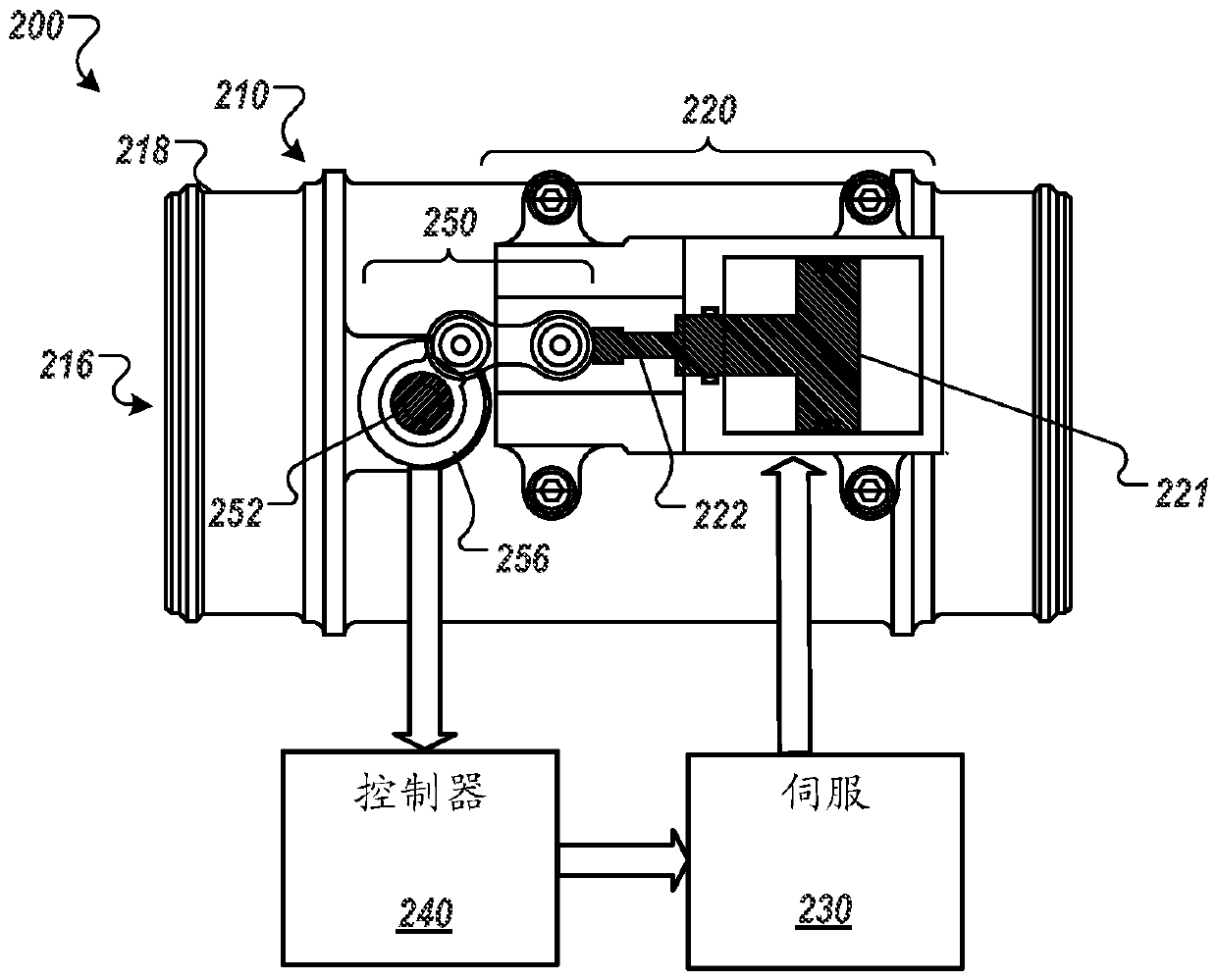

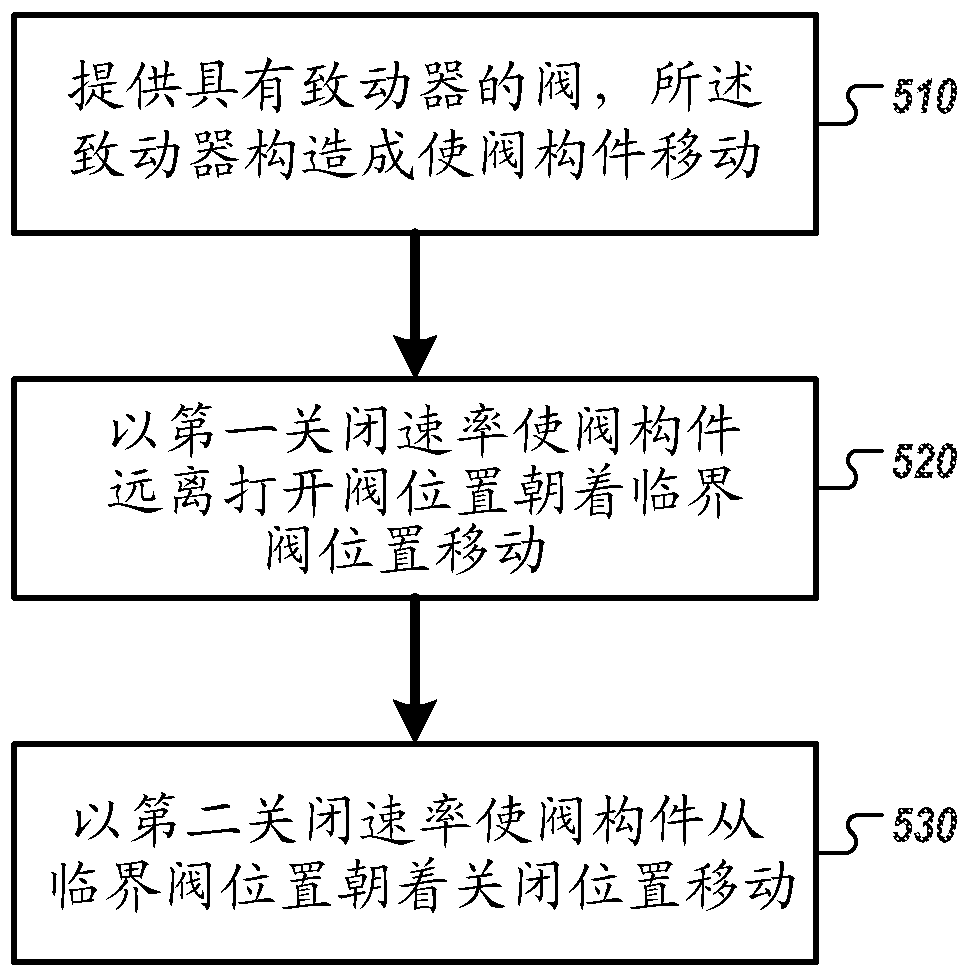

[0020] This document describes systems and techniques for controlling fluid flow using valves with variable stroke rates. Steam turbine valves are subject to small but cumulatively significant damage when the valve closes rapidly, such as during a shutdown. This makes the ability to rate limit the valve in the travel region near the valve seat highly desirable. The solution to this problem is complicated by the fact that the linkage to the steam turbine valve can grow or shrink significantly with temperature, so that the actual position of the valve seat is unknown to the control. As used herein, the term "valve seat" means the surface that the valve contacts to shut off the flow of fluid through the valve when the valve is closed. For example, on a poppet-style valve, the sealing surfaces must be tightly pressed against each other firmly, so they also act as a hard stop. If the sealing surfaces of the valves are damaged by impact, they may no longer seal well. Another comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com