Steel, product created from said steel, and manufacturing method thereof

A trace, sheet technology, used in the manufacture of tools, shafts and bearings, heat treatment furnaces, etc., which can solve the problem of high content of high-cost elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0138] The composition (expressed in weight percent) of the steel is determined based on the following considerations.

[0139] The Ni content is 10.0% to 24.5%, preferably 12.0% to 24.5%. under these circumstances:

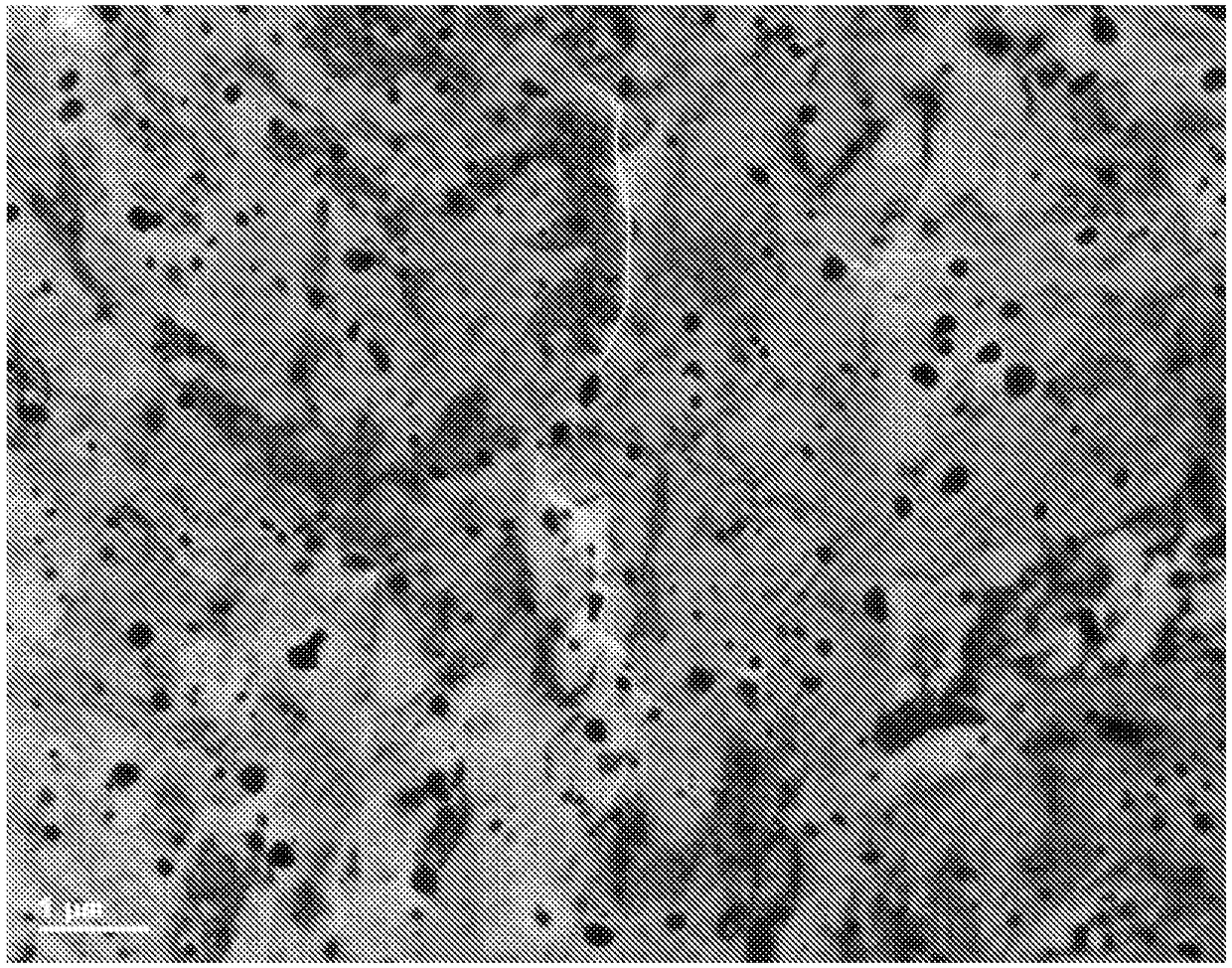

[0140] Firstly, by conventional heat treatment, a highly martensitic structure is obtained, i.e. meaning that at least 30%, more preferably at least 50% of the martensitic structure can be seen on the surface of the structure on a micrograph; irrespective of the heat treatment applied, more than A Ni content of 24.5% in combination with the required content of other elements will not be able to obtain this structure;

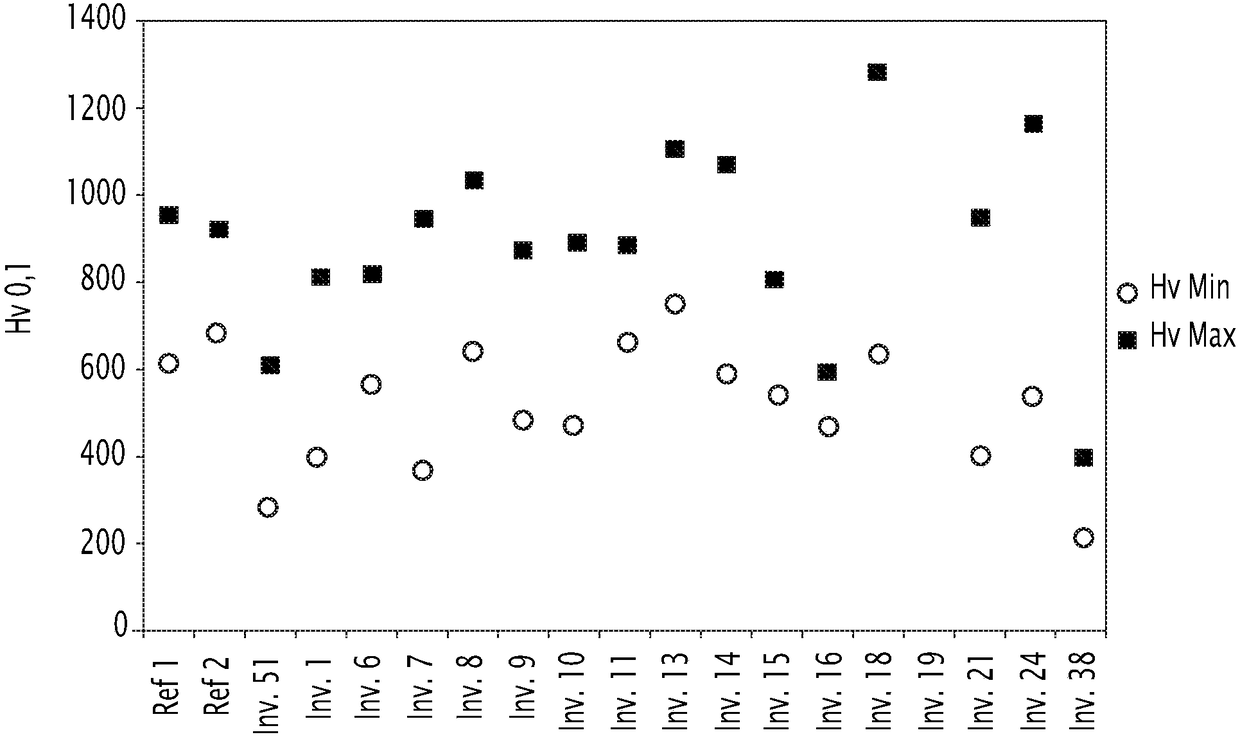

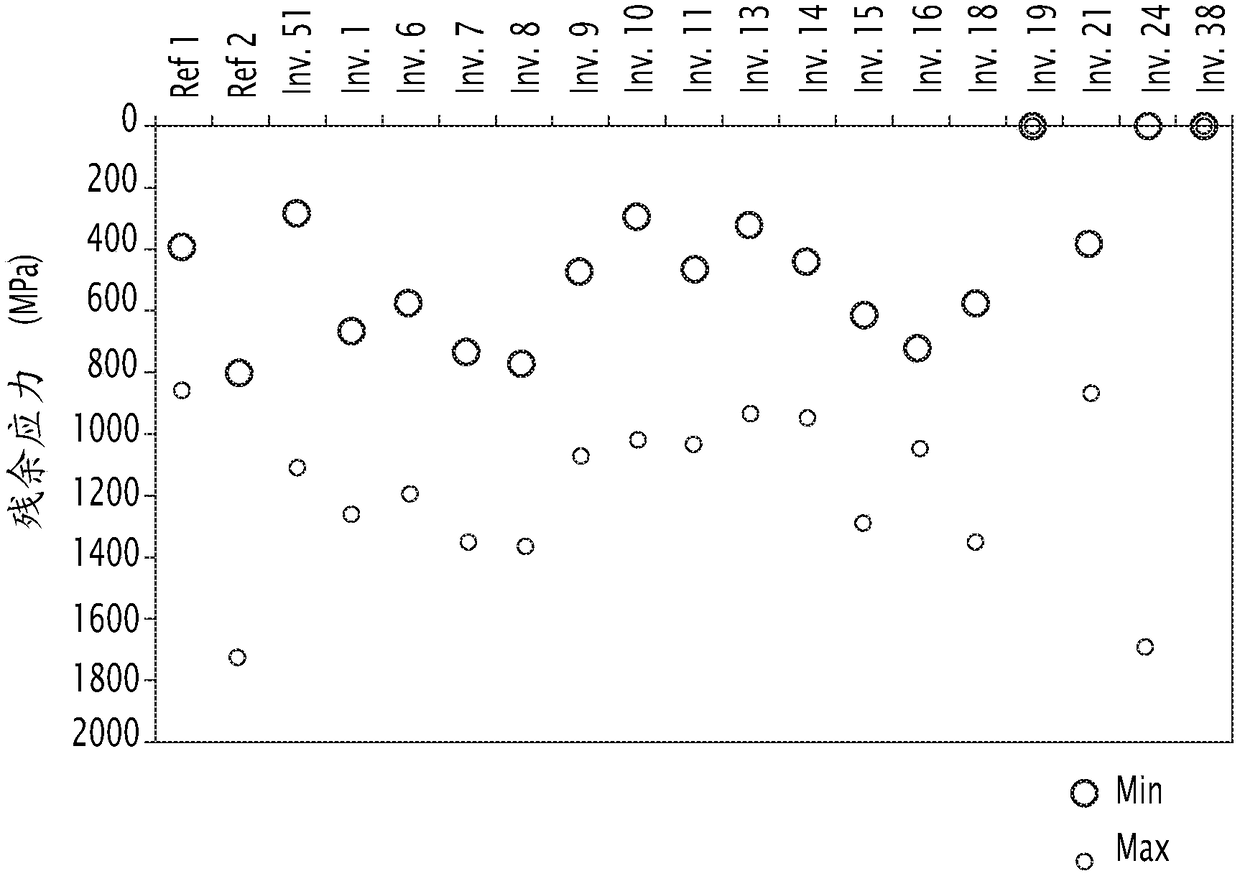

[0141] Secondly, after precipitation hardening, for the envisaged applications, advantageous properties are obtained, in particular ductility, expansibility, yield strength, K1C toughness; a minimum Ni content of 10.0%, the associated defined proportions of Co, Mo and other metal elements It is suitable to obtain this property; a minimum Ni conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com