Electric vehicle control device, electric vehicle control system, and electric vehicle control method

An electric vehicle and control device technology, which is applied in the direction of road vehicle drive control system, control device, ASR control system, etc., can solve problems such as inability to accurately suppress vibration, signal without sign, and inability to identify rotation direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

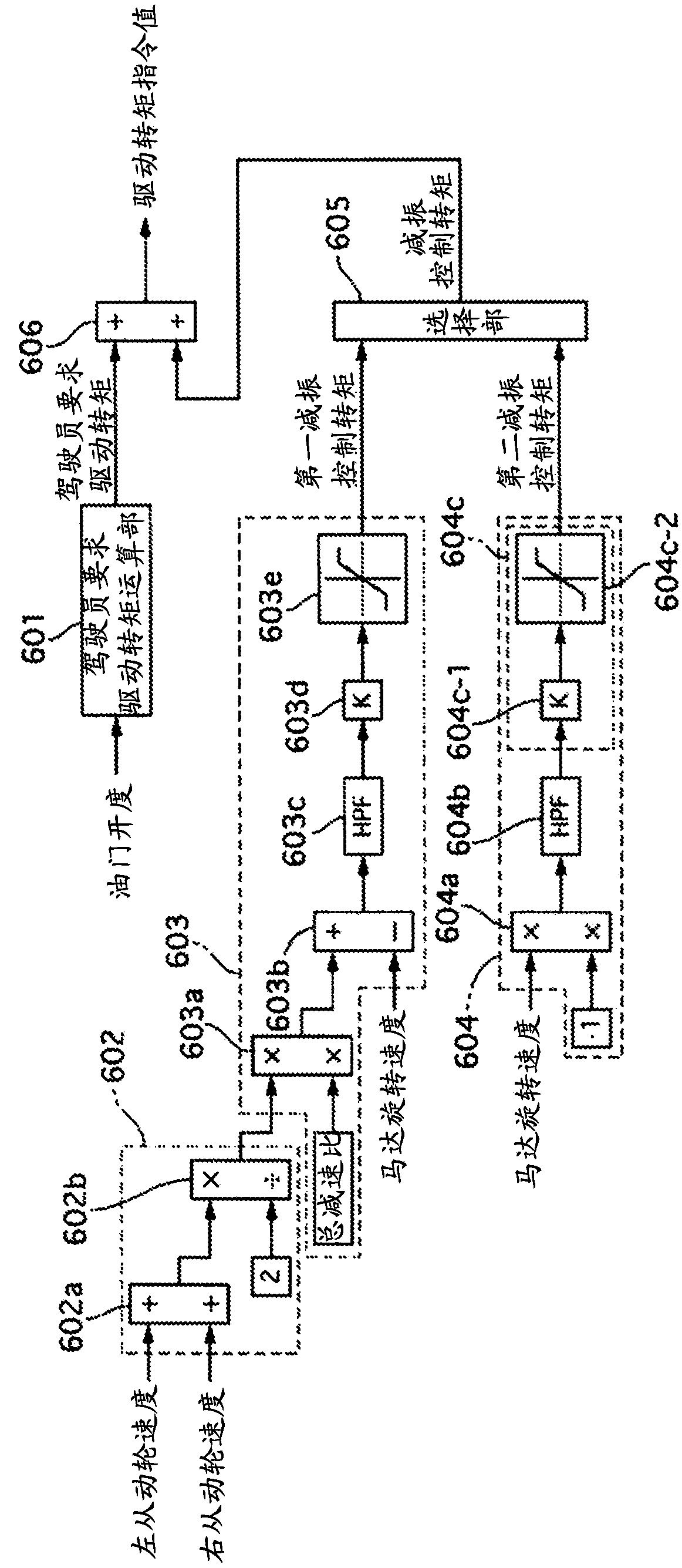

[0020] figure 1 It is a system diagram of the electric vehicle of the first embodiment. The electric vehicle of the first embodiment is a front-wheel drive vehicle (two-wheel drive vehicle) in which the front wheels FL and FR are driven by an electric motor 1. The differential gear 3 is connected to the electric motor 1 via the reduction mechanism 2. A drive shaft 4 is connected to the differential gear 3. Front wheels FL and FR are connected to the drive shaft 4. Electric power is supplied to the electric motor 1 via an inverter 5 from a high-voltage battery (not shown). The driving of the inverter 5 is controlled by the vehicle controller 6.

[0021] The electric vehicle has a shift lever 12 that outputs a gear signal indicating the driving mode of the vehicle, an accelerator opening sensor 7 that outputs an accelerator opening signal, and a resolver 8 that outputs a motor rotation speed signal including the rotation direction of the electric motor 1. The vehicle controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com