Improving temperature drift compensation by controlled over-compensation

An over-compensation, controller technology, applied in general control systems, program control, control/regulation systems, etc., to solve problems such as uncovered workspace, residual drift, and failure to consider temperature-related effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

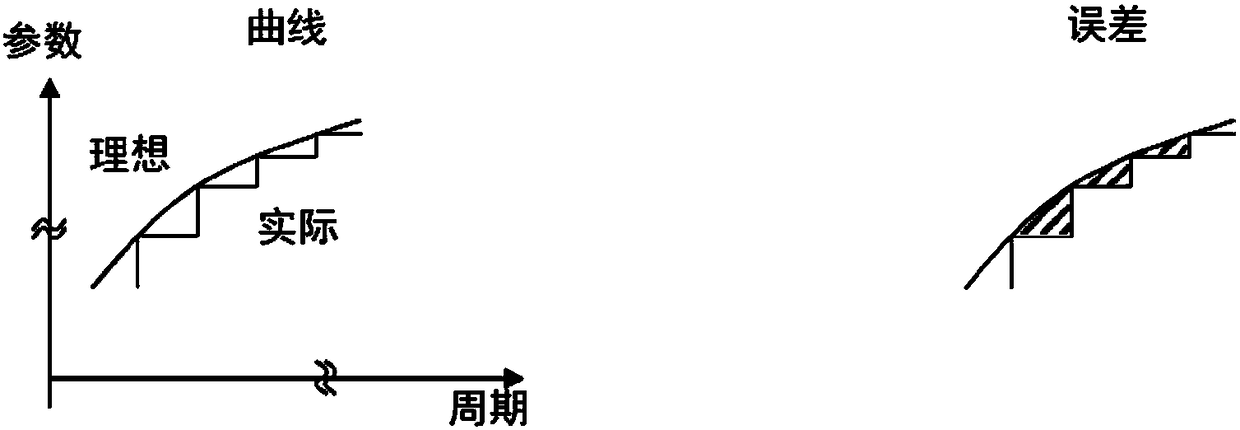

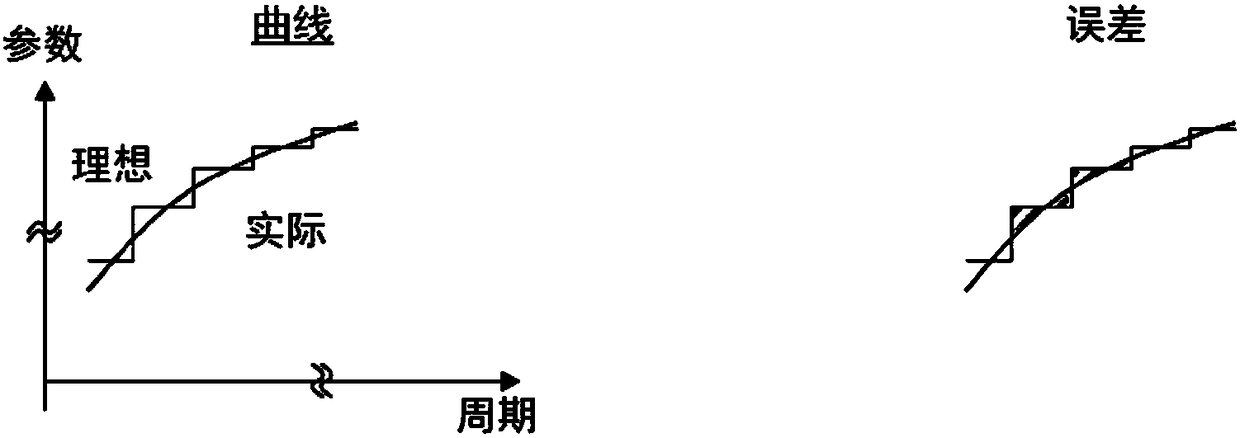

[0026] figure 1 and figure 2The parameter curves for a number of cycles are shown separately. Here, the parameters are manipulator parameters for controlling the manipulator. In the figures, the continuous lines represent the ideal curves of the parameters during these cycles. The parameters change due to temperature-dependent influences which occur, for example, during the warm-up phase of the manipulator. Especially at the beginning of the warm-up phase, the temperature rise can be very steep. Therefore, the manipulator parameters have a strong time dependence. In the best case, the currently used manipulator parameters agree with the ideal parameters at every point in time.

[0027] same as figure 1 As shown, the manipulator parameters are usually tuned to match ideal values at the beginning of a cycle. For this purpose, for example, the usual temperature drift compensation can be used. The adjusted manipulator parameters remain constant during a duty cycle. Fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com