Aerosol-generating system with self-activated electric heater

An aerosol generation and electric heater technology, which can be used in inhalers, tobacco, tobacco processing, etc., can solve the problems of adverse effects on the accuracy of consumption, and the consumption is not estimated accurately enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

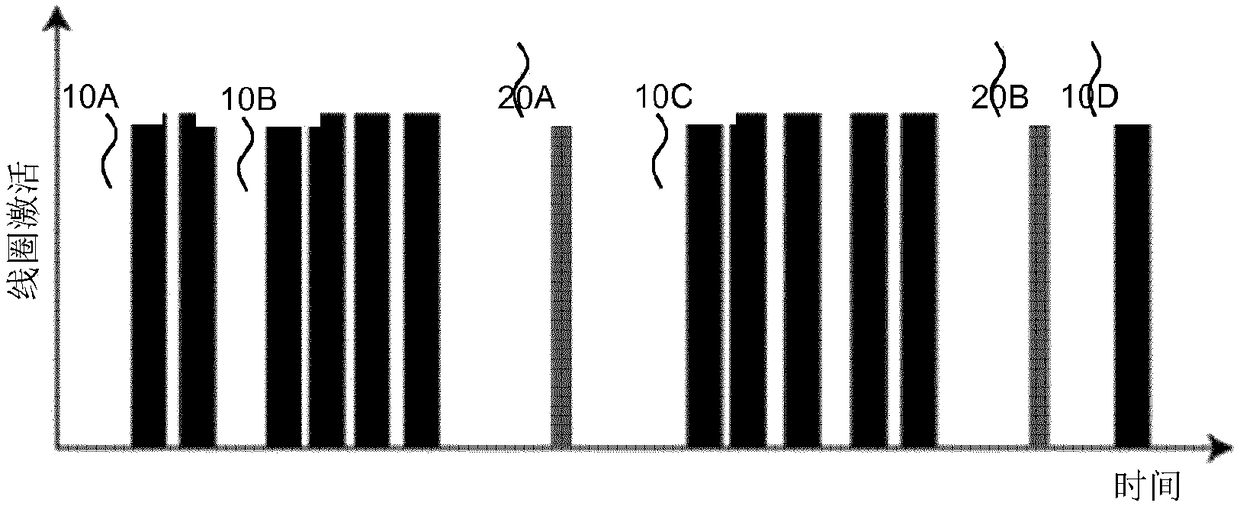

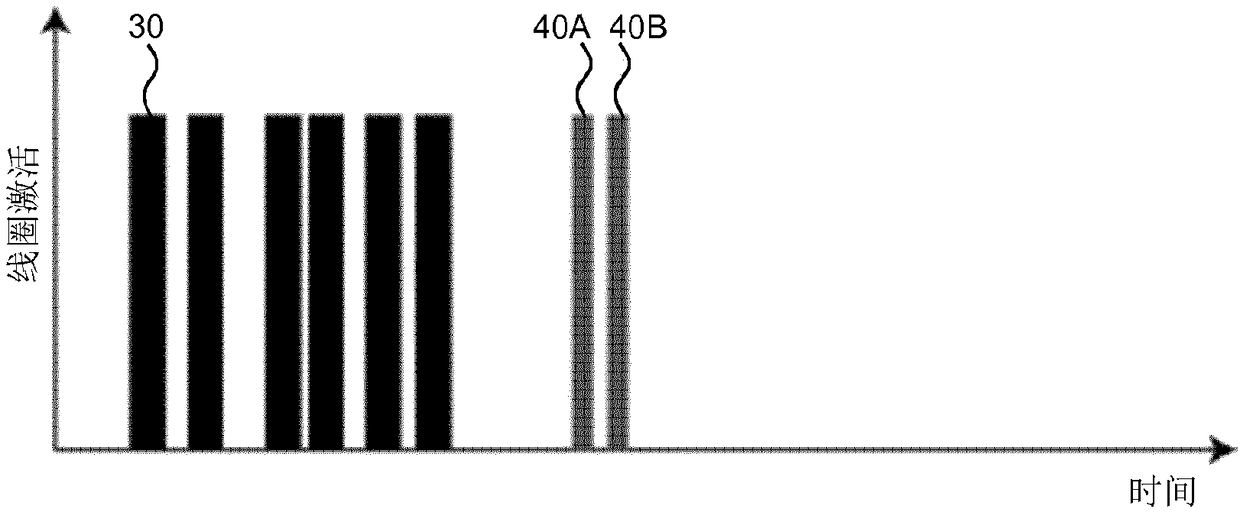

[0064] figure 1 Coil activation over time is shown according to a first embodiment of an aerosol generating system comprising a heating coil and a wick delivering a liquid aerosol-forming substrate from a liquid storage portion to an electric heater. The plots indicate the timing and duration of individual coil activations. The coil may be activated in response to a user generating an aerosol, for example by taking a puff request, or by self-excitation of the electric heater during inactive periods of the electric heater. Coil activation 10A is the first activation of the electric heater caused by the first series of pumps. Coil activation 10B represents the first puff of the second series of puffs occurring after a pause. The pause is short enough that self-excitation of the electric heater cannot occur between the first and second series of puffs initiated by coil activation 10A and 10B. After the second series of puffs, there was a pause long enough for the self-excited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com