Aerosol generating article, aerosol-generating system and method for manufacturing an aerosol-generating article

An aerosol generation, aerosol technology, applied in the manufacture of cigarettes, cigars, applications, etc., to achieve the effect of efficient use and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

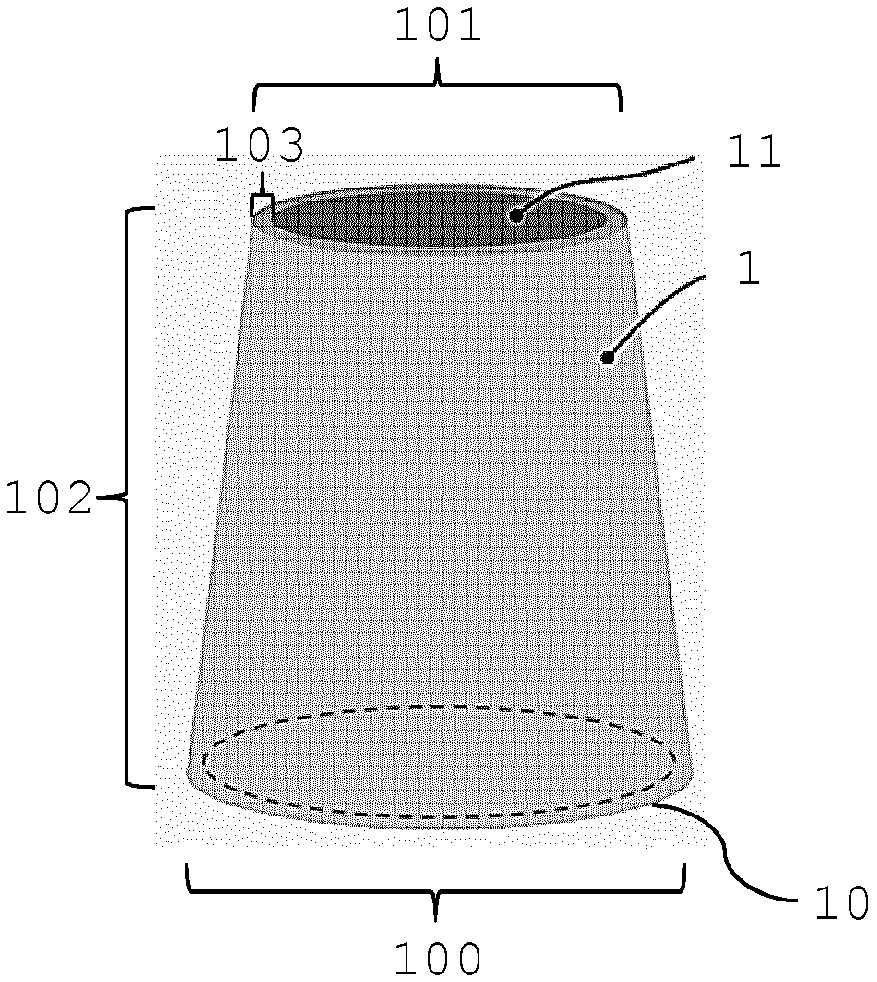

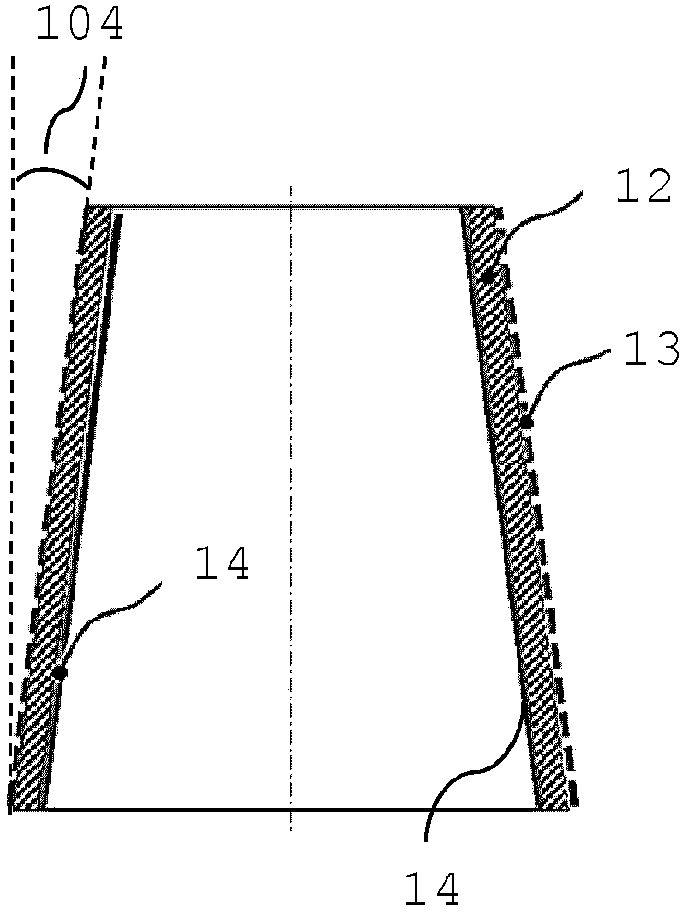

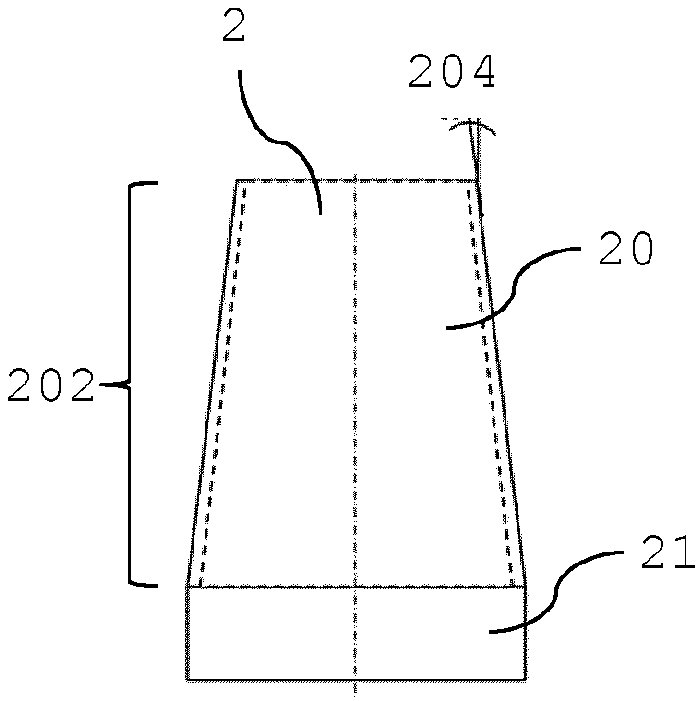

[0102] figure 1An aerosol-generating article 1 is shown in the form of a truncated cone with an open top 11 and an open bottom 10 . The cone is made of an aerosol-forming substrate, preferably a tobacco-containing substrate. The outer diameter 100 of the base 10 of the cone is between 5 mm and 8 mm. The outer diameter 101 of the top 11 of the cone is between 5mm and 8mm. The height 102 of the cone is between 4mm and 15mm. The wall thickness 103 of the cone is between 0.3 mm and 1 mm. The thickness 103 may vary along the height 102 of the cone depending on the intended aerosolization properties of the article. The apex angle 104 of the article 1 is between 2 and 10 degrees. Apex angle 104 indicated at figure 2 (for illustrative reasons of suction from the base 10 of the cone), the figure shows a cross-section of an aerosol-generating article in the form of a truncated cone. The aerosol-forming substrate 12 is provided on its exterior with a layer 13 of porous material s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com