A cam mechanism type ship sloshing simulation device

A technology of cam mechanism and simulation device, which is applied in the direction of measuring device, machine/structural component test, instrument, etc., can solve the problems of complex structure, high cost, and complicated implementation steps, and achieve the goal of less structure and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

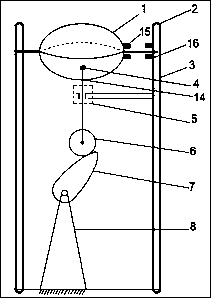

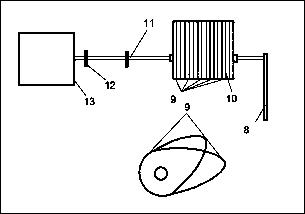

[0024] Such as figure 1 , figure 2 and image 3 As shown, the described a kind of cam 9 mechanism type ship sloshing simulation device includes: a frame 3, a control terminal, a ship model with a magnet, and a sealed hollow ellipsoid experimental cabin 1 that can be made according to the scale ratio. Ship model, the bottom of the ship model is provided with a magnet, and the interior of the ship model is provided with a detection black box; the openable sealed hollow ellipsoid experiment cabin 1 is filled with a simulated environment liquid and a ship model with a magnet is placed inside, and the push rod 14 is installed on the The spherical pair 4 on the side of the experimental cabin 1 is connected to the side shaft 2 through the side bearing 15 arranged on the other side of the experimental cabin; the driven wheel 6 is slidably connected to the power cam group 7 and hinged to the bottom end of the push rod 14; Rod 14, the top is connected with the side of the openable se...

Embodiment 2

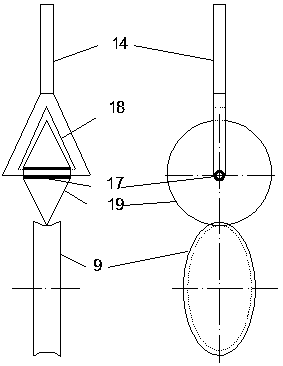

[0033] Such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, embodiment 2 is basically the same as embodiment 1, the difference is that the driven wheel 6 includes: an H-shaped round bracket 20, which is symmetrically installed by two rotating pieces 21 and connected to each other through a connecting rod 22 in the middle, and is arranged in the power The cam group is just above the cam group, it works with the power cam group, and is slidingly connected with the ejector rod bearing 23; 14 fixed connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com