Front suspension camber angle detection system

A detection system and a camber angle technology, applied in the field of detection systems, can solve the problems of rising manufacturing costs, no device designed to measure the camber angle of the front overhang, etc., and achieve the effects of a high degree of automation in operation, a fast detection and diagnosis process, and reduced work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

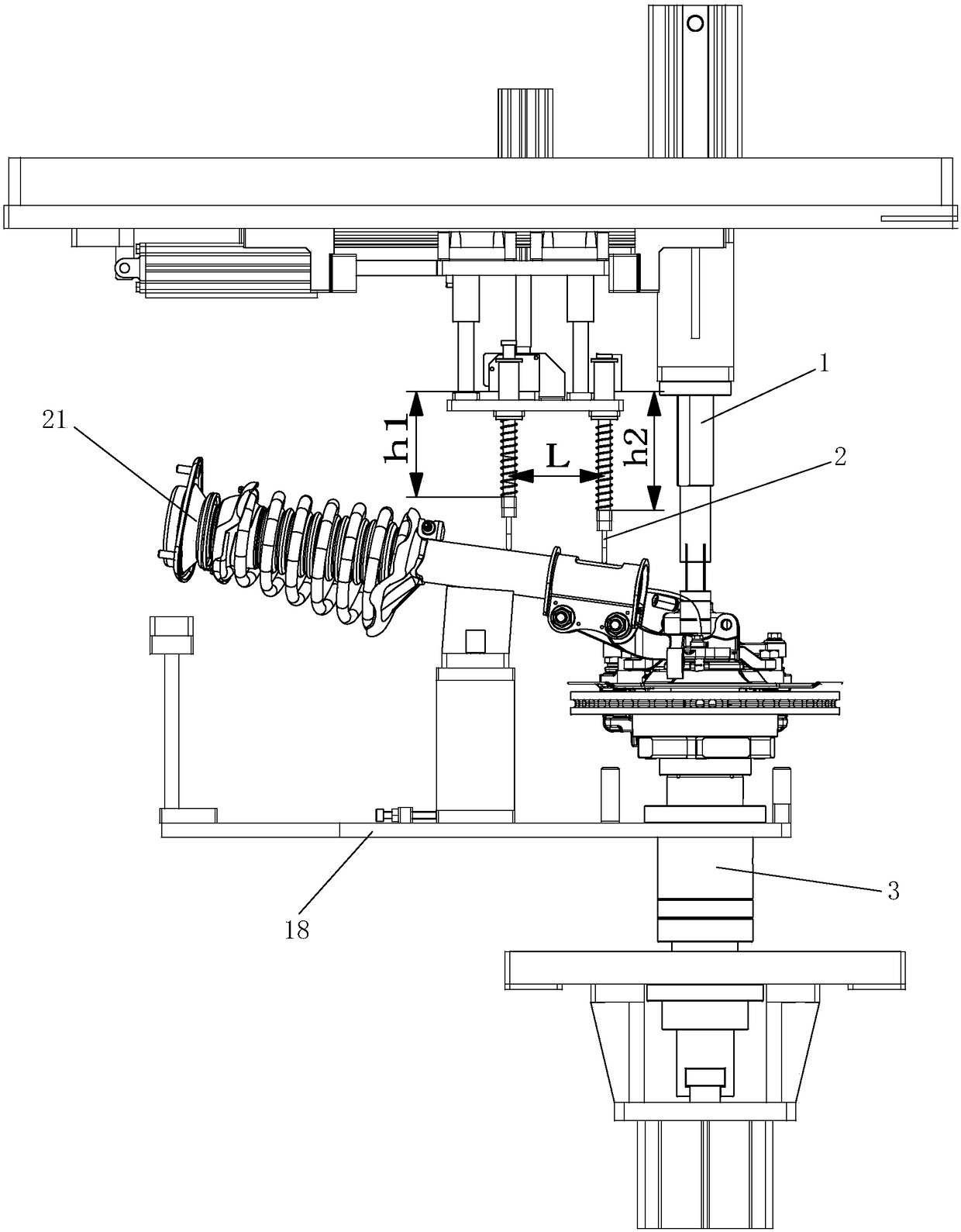

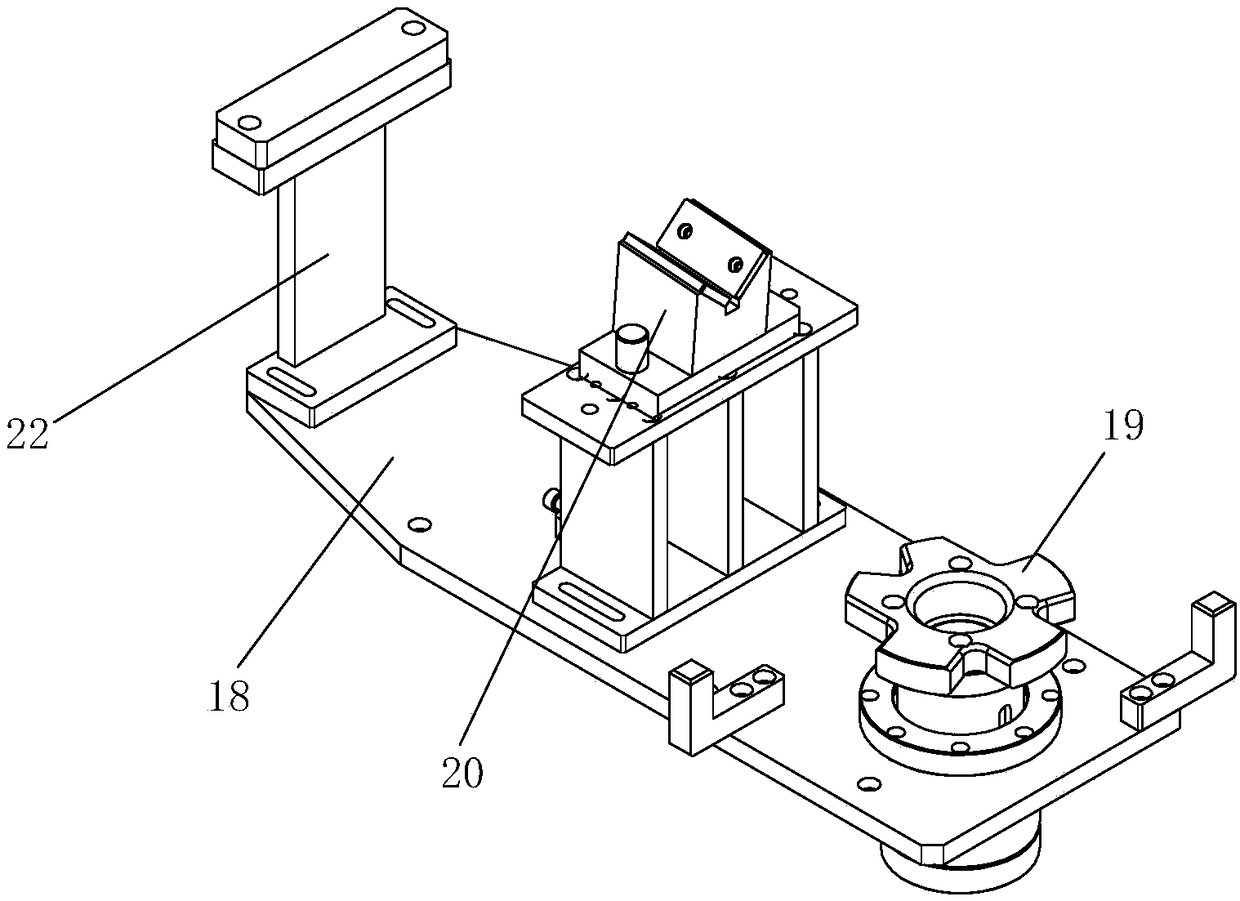

[0022] A front suspension camber angle detection system, comprising a pressing mechanism, a detection mechanism, a lifting mechanism, a front suspension rotary assembly platform, a tooling board and an industrial computer, the compression mechanism and the detection mechanism are arranged on the front suspension rotary assembly platform through a bracket Above, the lifting mechanism is set under the front suspension rotating assembly platform through the bracket. The detection mechanism includes measuring head I, measuring head II, sensor, measuring head connecting plate, cylinder I, cylinder IV and horizontal connecting plate. The cylinder I is set on the support, the connecting plate of the measuring head is connected with the cylinder I, the sensor is set on the connecting plate of the measuring head, the measuring head I and the measuring head II are respectively set on the measuring head through springs On the connecting plate, the cylinder IV is fixedly arranged on the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com