Chipping device of efficient bamboo chipper

A slicing machine and bamboo technology, which is applied in the directions of wood splitting devices, mechanical equipment, and mechanical processing of plant materials, can solve the problems of low slicing efficiency and achieve the effect of improving slicing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

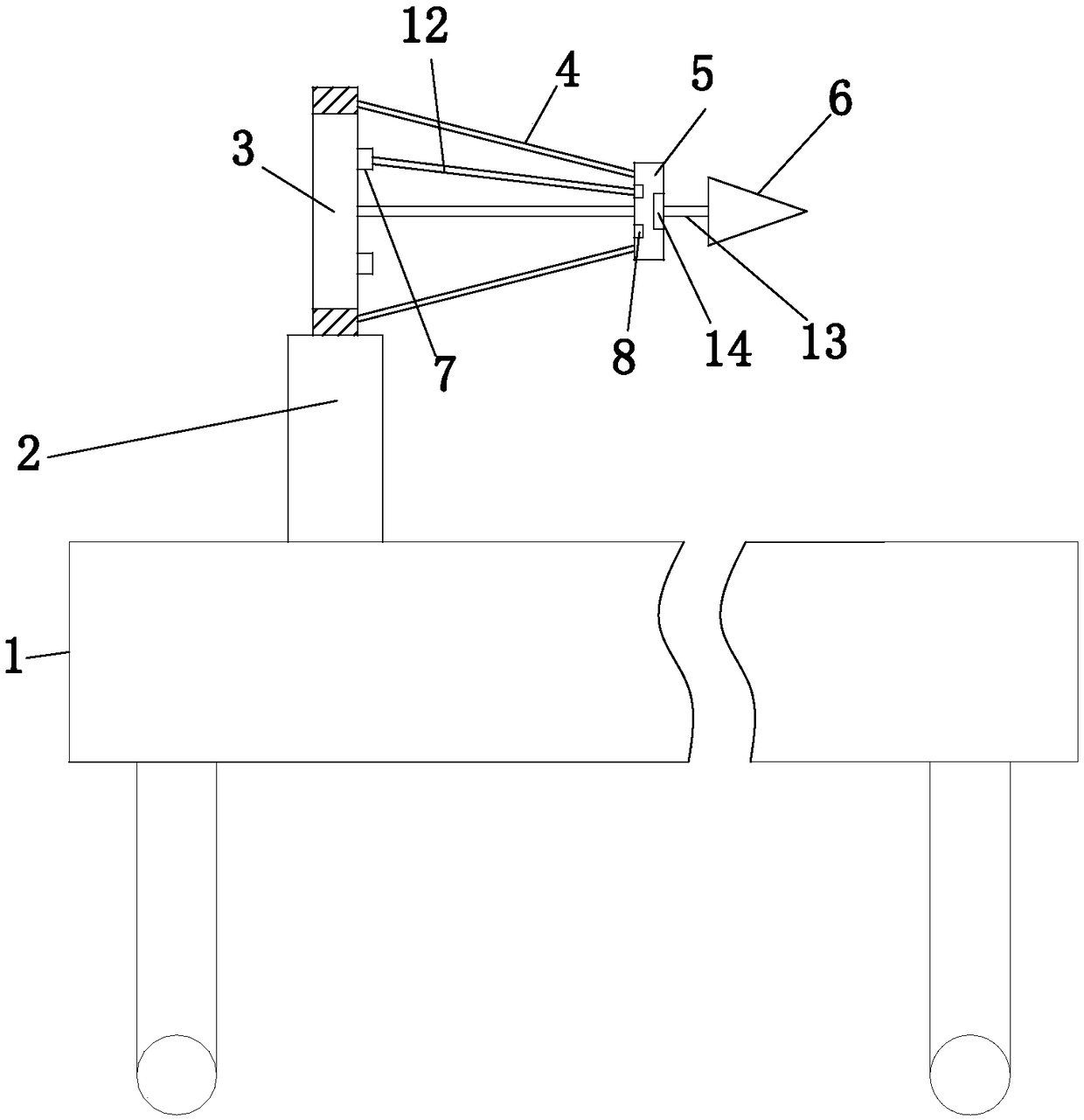

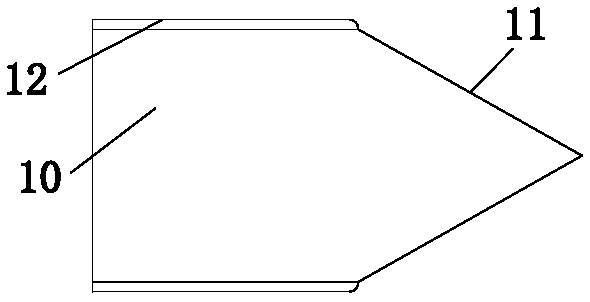

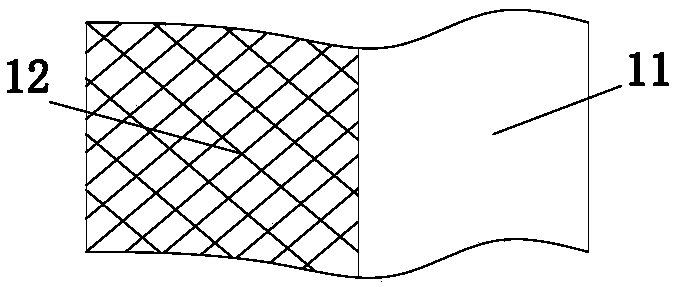

[0014] Example. A kind of opening device of high-efficiency bamboo slicer, constitutes as Figure 1 to Figure 3 As shown, including frame 1, frame 1 is provided with fixed support 2, and fixed support 2 is provided with ring frame 3, and the side of ring frame 3 is provided with a group of fixed blades 4 that are arranged in conical structure, and fixed blade 4 ends A fixed plate 5 is provided at the top of the fixed plate 5, and a wall breaking knife 6 is provided on the side of the fixed plate 5; a plurality of first installation bayonets 7 are uniformly provided on the ring frame 3, and a plurality of first installation bayonets 7 are evenly provided on the fixed disk 5. Corresponding second installation bayonet 8, be provided with movable blade 9 between two adjacent first installation bayonet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com