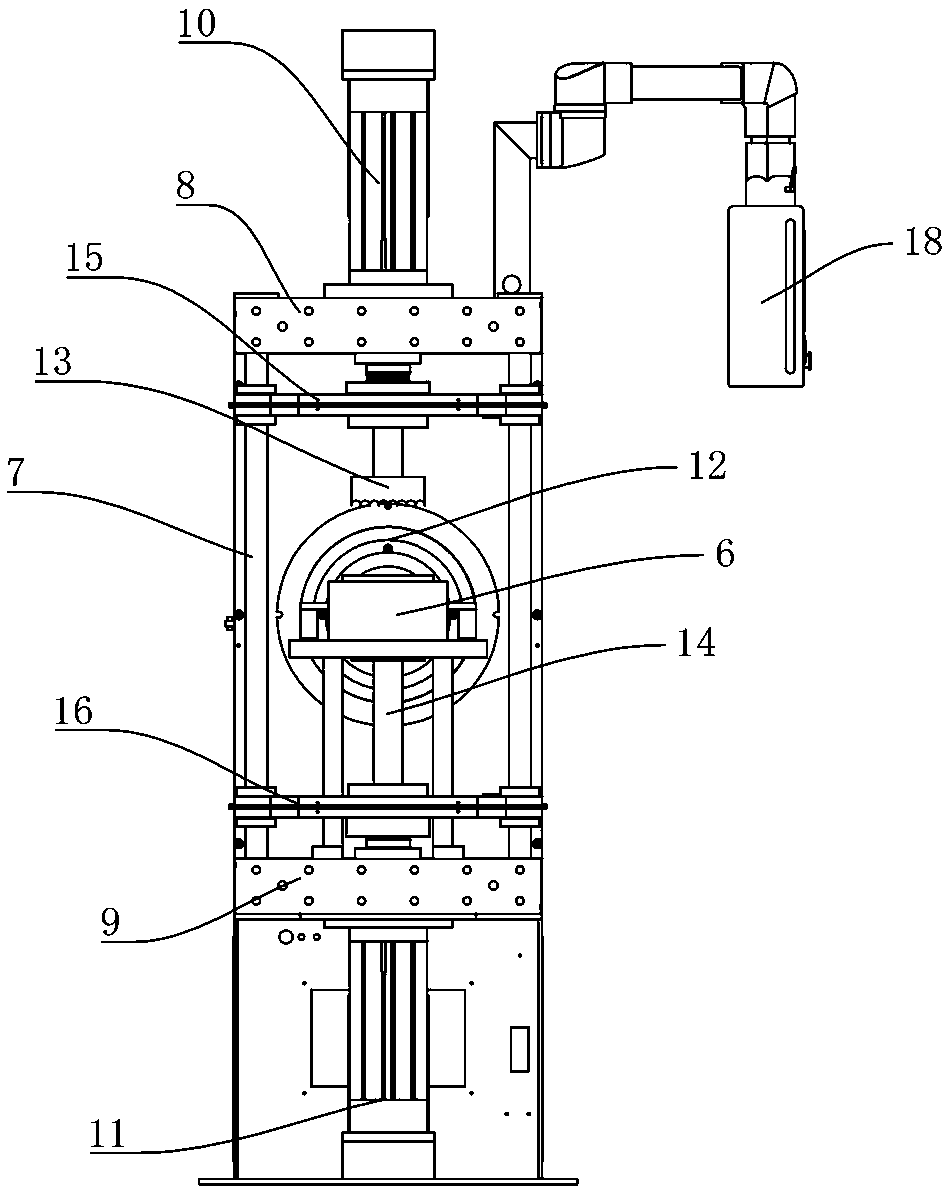

Full servo automatic press

An automatic press and servo technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problem of low scrap rate, and achieve the effect of low scrap rate, high control accuracy, and less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0024] Examples, see Figure 1 to Figure 3 Shown: a full-servo automatic press, including a frame 1, on which a barrel 2, a powder weighing device 3, a feeding device 4 and a forming device 5 are hermetically installed, and the material barrel 2 is located on the powder weighing device 3 Above, the frame 1 is also equipped with an air hammer that cooperates with the material barrel 2 to prevent the accumulation of NdFeB powder in the material barrel 2, and ensure that the NdFeB powder in the material barrel 2 can smoothly enter the weighing device 3, Stairs are also provided beside the frame 1, and because the position of the material tank 2 is relatively high, it is convenient to feed materials in the material tank 2 through the stairs. The powder weighing device 3, the feeding device 4 and the forming device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com