Flue gas desulfurization efficiency enhancing agent for wet flue gas desulfurization system, and preparation method and application of flue gas desulfurization efficiency enhancing agent

A wet desulfurization and flue gas technology, applied in the field of desulfurization process, can solve the problems of the desulfurization system being unable to operate normally, the clogging of the absorption tower equipment, the poor adaptability of the sulfur content of the coal, etc., to promote the absorption of sulfur dioxide and achieve good environmental benefits. and economic benefits, the effect of shortening the desulfurization reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

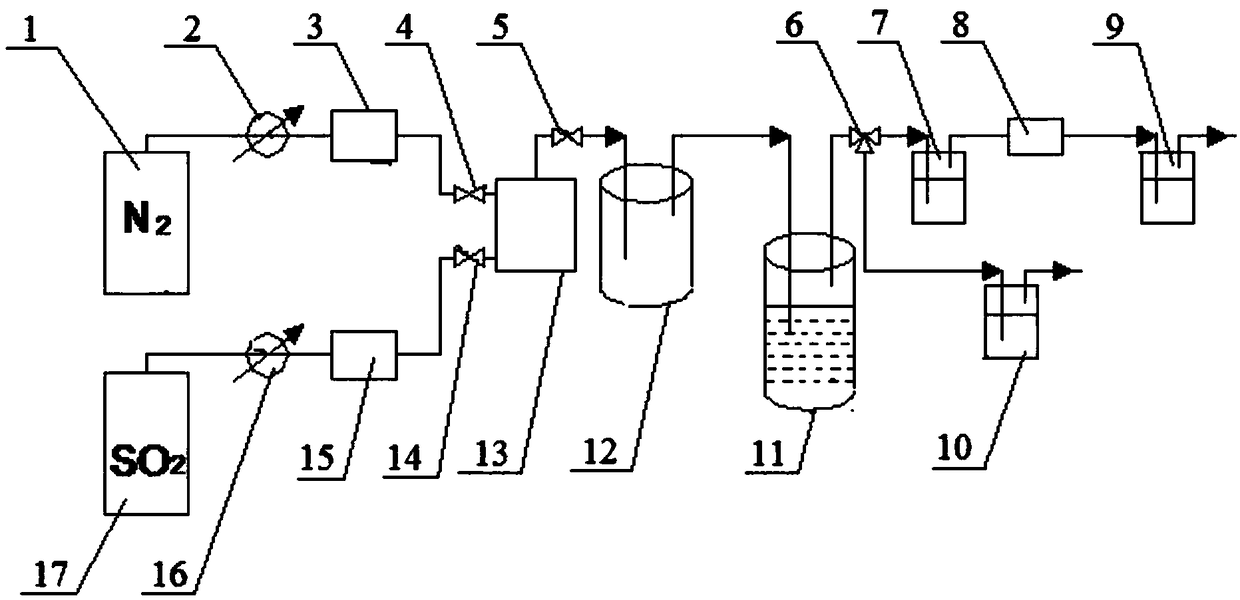

Image

Examples

Embodiment 1

[0030] The flue gas desulfurization efficiency enhancer used in wet desulfurization system, by weight percentage, its composition and content are as follows: adipic acid 68%, sodium adipate 6%, succinic acid 16%, sodium succinate 5% , glutaric acid 5%;

[0031] The preparation method of the flue gas desulfurization efficiency-enhancing agent specifically comprises the following steps: after mixing adipic acid, sodium adipate, succinic acid, sodium succinate and glutaric acid in the formula amount and stirring evenly, the obtained The above-mentioned flue gas desulfurization efficiency-enhancing agent.

Embodiment 2

[0033] The flue gas desulfurization efficiency enhancer used in the wet desulfurization system has the following composition and content by weight percentage: 70% adipic acid, 5% sodium adipate, 15% succinic acid, and 5% sodium succinate , glutaric acid 5%;

[0034] The preparation method of the flue gas desulfurization efficiency-enhancing agent specifically comprises the following steps: after mixing adipic acid, sodium adipate, succinic acid, sodium succinate and glutaric acid in the formula amount and stirring evenly, the obtained The above-mentioned flue gas desulfurization efficiency-enhancing agent.

Embodiment 3

[0036] The flue gas desulfurization efficiency enhancing agent used in wet desulfurization system has the following composition and content in terms of weight percentage: 71% adipic acid, 6% sodium adipate, 13% succinic acid, and 6% sodium succinate , glutaric acid 4%;

[0037] The preparation method of the flue gas desulfurization efficiency-enhancing agent specifically comprises the following steps: after mixing adipic acid, sodium adipate, succinic acid, sodium succinate and glutaric acid in the formula amount and stirring evenly, the obtained The above-mentioned flue gas desulfurization efficiency-enhancing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com