Aquatic feed stirring granulatingdevice for groupers

An aquatic feed, mixing and granulation technology, applied in the direction of feed, animal feed, and animal feed molding or processing, can solve the problems of inability to weigh feed, inability to granulate feed, and unfavorable staff operations, saving time and efficiency. The effect of labor force, work efficiency improvement, and work quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

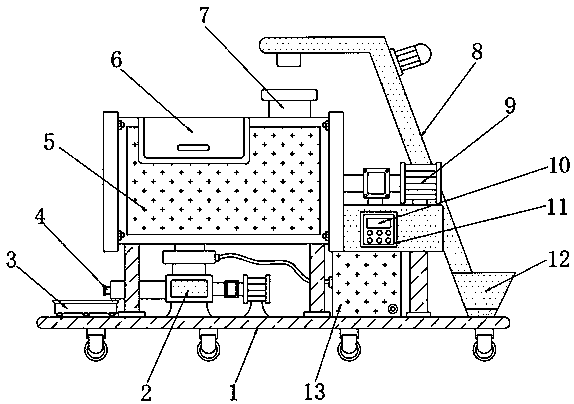

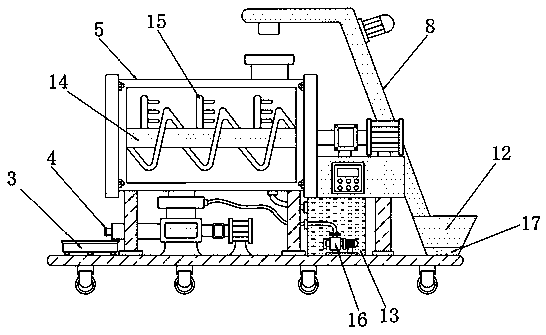

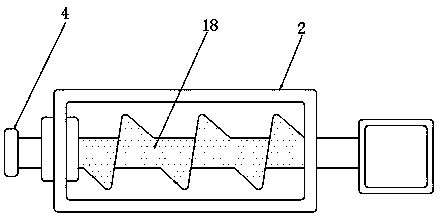

[0026] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a grouper aquatic feed mixing and granulation device, including a base 1, the upper end of the base 1 is provided with a granulation box 2, and the upper end of the base 1 is close to the bottom of the granulation box 2 A grain outlet 4 is provided at one end, a collection tank 3 is provided at the upper end of the base 1 near the grain outlet 4, and a water tank 13 is provided at the upper end of the base 1 near the granulation box 2, The upper end of the base 1 is provided with an upper hopper 12 near the side of the water tank 13, the upper end of the upper hopper 12 is provided with a feeder 8, the upper end of the granulation box 2 is provided with a mixing box 5, and the upper end of the mixing box 5 is provided with an inlet. The feed opening 7, and the upper end of the mixing box 5 is provided with an inspection door 6 near the side position of the feeding opening 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com