Novel data cable and manufacture process thereof

A cable and data technology, applied in the field of new data cables and their manufacturing processes, can solve problems such as reducing production costs, restricting the production efficiency of data cables, and affecting the transmission performance of inner core wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

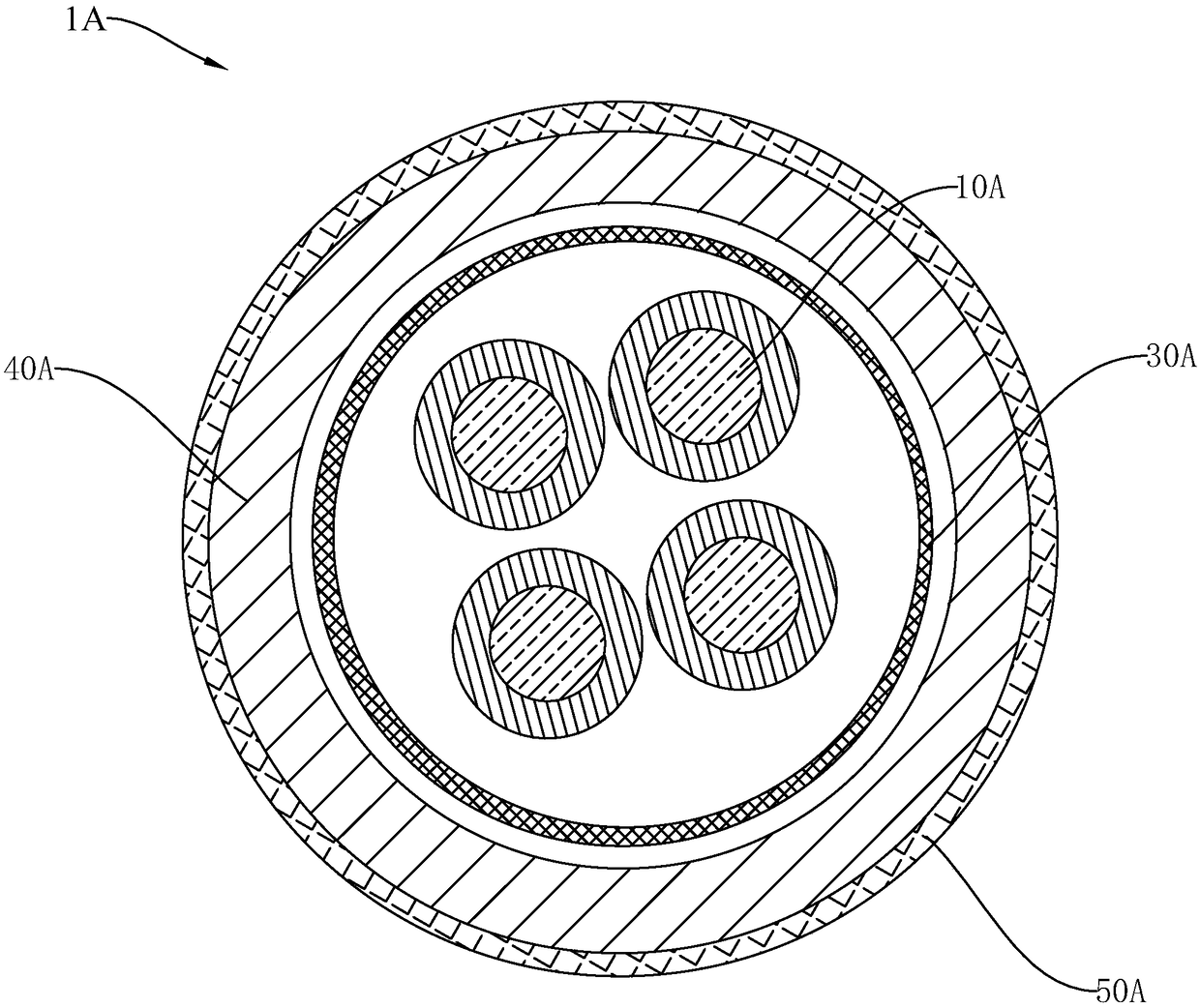

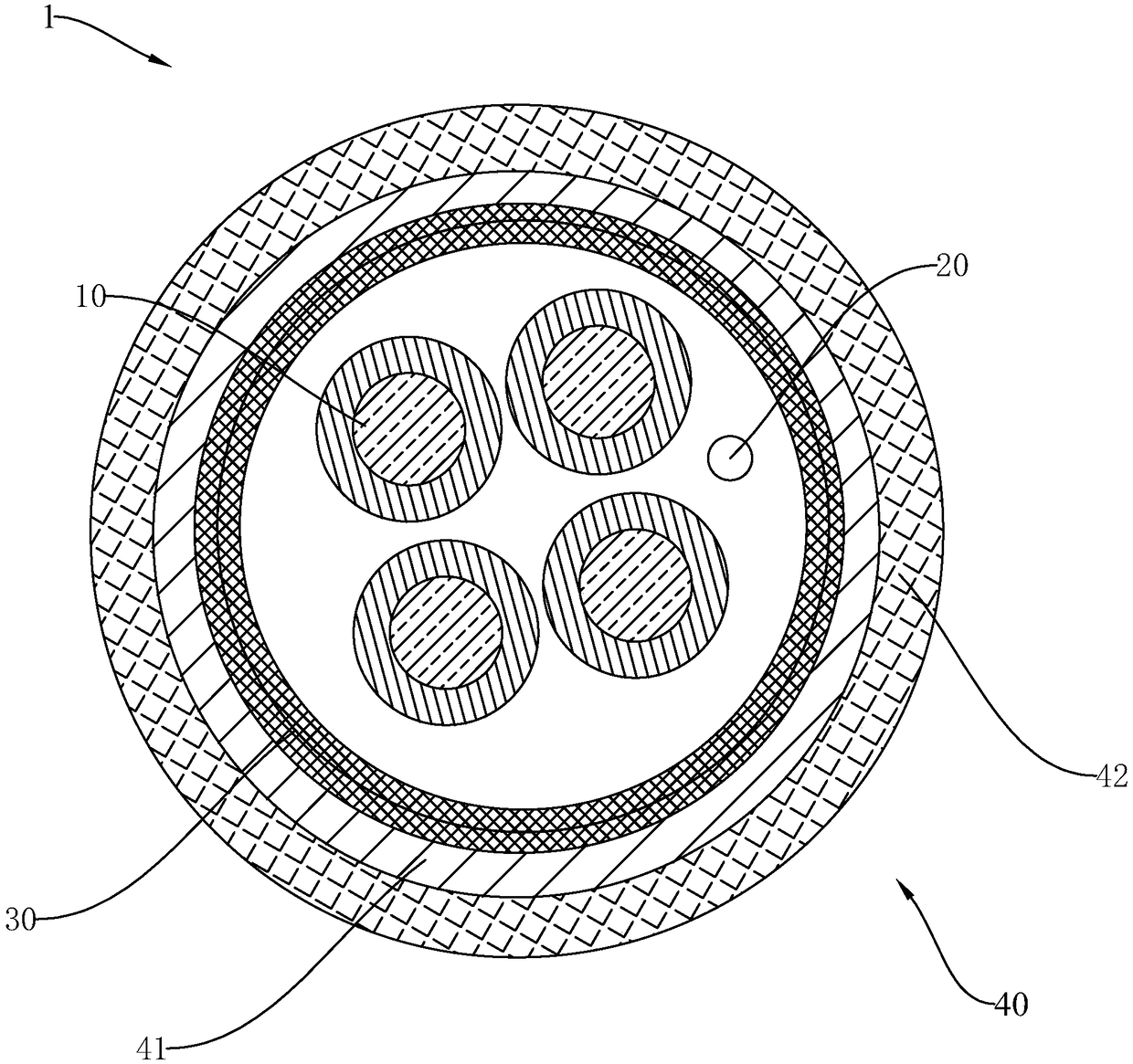

[0049] A manufacturing process of a novel data cable 1, comprising the steps of:

[0050] (1) 10 inner core wires are twisted into a cable;

[0051] (2) Double-sided aluminum foil wraps a plurality of inner core wires 10 and a ground wire 20 to form a double-sided aluminum foil layer 30; and

[0052] (3) feeding, setting the feeding speed, and uniformly transmitting the cable coated with the double-sided aluminum foil layer 30, wherein the feeding speed is 100m / min;

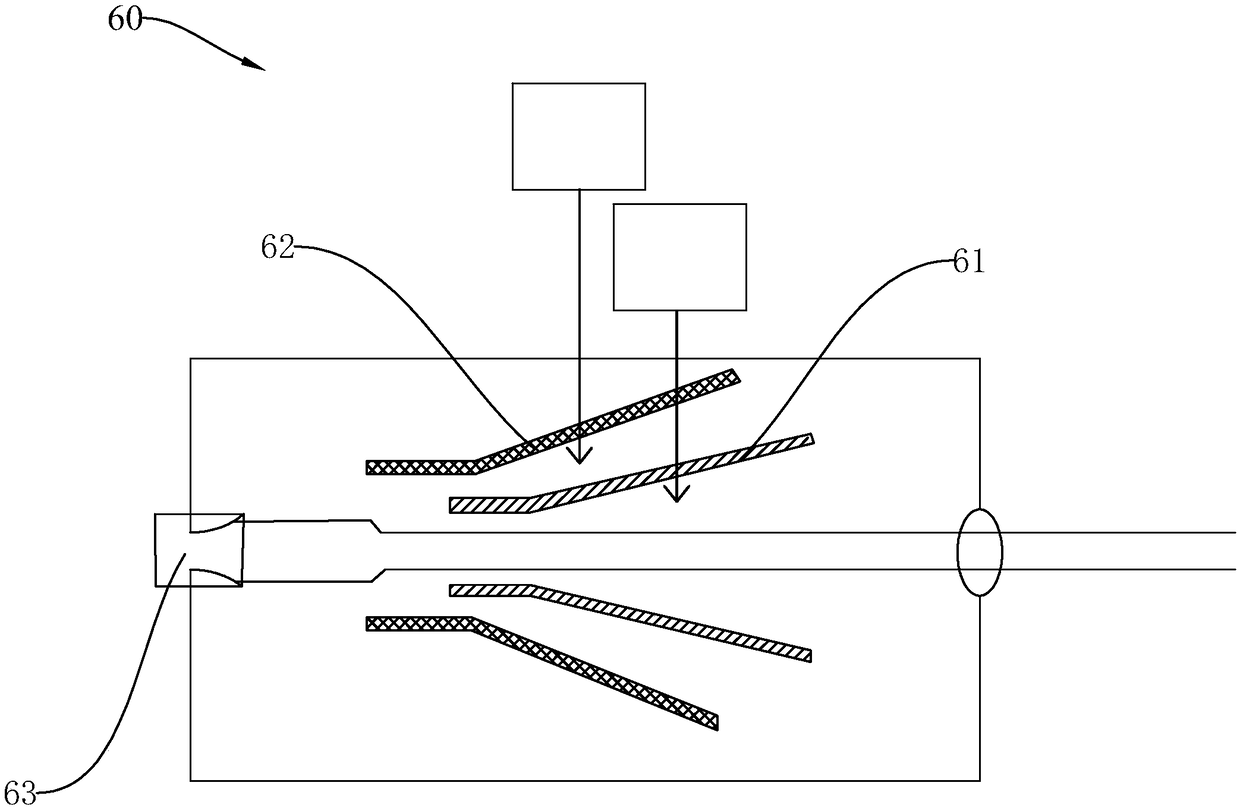

[0053] (4) Feeding, adding the conductive rubber material to the first inner mold 61 of the double-layer wall compactor 60, adding the outer wall rubber material to the second inner mold 62 of the double-layer wall compactor 60, and in the process of transmission, conductive The rubber material is firstly fed on the outer surface of the double-sided aluminum foil layer 30 synchronously, and the outer wall rubber material is then synchronously fed on the outer surface of the conductive rubber material of the cabl...

Embodiment 2

[0057] A manufacturing process of a novel data cable 1, comprising the steps of:

[0058] (1) 10 inner core wires are twisted into a cable;

[0059] (2) Double-sided aluminum foil wraps a plurality of inner core wires 10 and a ground wire 20 to form a double-sided aluminum foil layer 30; and

[0060] (3) feeding, setting the feeding speed, and uniformly transmitting the cable coated with the double-sided aluminum foil layer 30, wherein the feeding speed is 130m / min;

[0061] (4) Feeding, adding the conductive rubber material to the first inner mold 61 of the double-layer wall compactor 60, adding the outer wall rubber material to the second inner mold 62 of the double-layer wall compactor 60, and in the process of transmission, conductive The rubber material is firstly fed on the outer surface of the double-sided aluminum foil layer 30 synchronously, and the outer wall rubber material is then synchronously fed on the outer surface of the conductive rubber material of the cabl...

Embodiment 3

[0065] A manufacturing process of a novel data cable 1, comprising the steps of:

[0066] (1) 10 inner core wires are twisted into a cable;

[0067] (2) Double-sided aluminum foil wraps a plurality of inner core wires 10 and a ground wire 20 to form a double-sided aluminum foil layer 30; and

[0068] (3) feeding, setting the feeding speed, and uniformly transmitting the cable coated with the double-sided aluminum foil layer 30, wherein the feeding speed is 120m / min;

[0069] (4) Feeding, adding the conductive rubber material to the first inner mold 61 of the double-layer wall compactor 60, adding the outer wall rubber material to the second inner mold 62 of the double-layer wall compactor 60, and in the process of transmission, conductive The rubber material is firstly fed on the outer surface of the double-sided aluminum foil layer 30 synchronously, and the outer wall rubber material is then synchronously fed on the outer surface of the conductive rubber material of the cabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com