Synthesis method of cellulose carbonate material and application of cellulose carbonate material

A synthesis method and technology of cellulose, applied in the direction of additive processing, etc., can solve the problems of high price of ionic liquid, limited economic performance, high cost of recovery, purification, and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

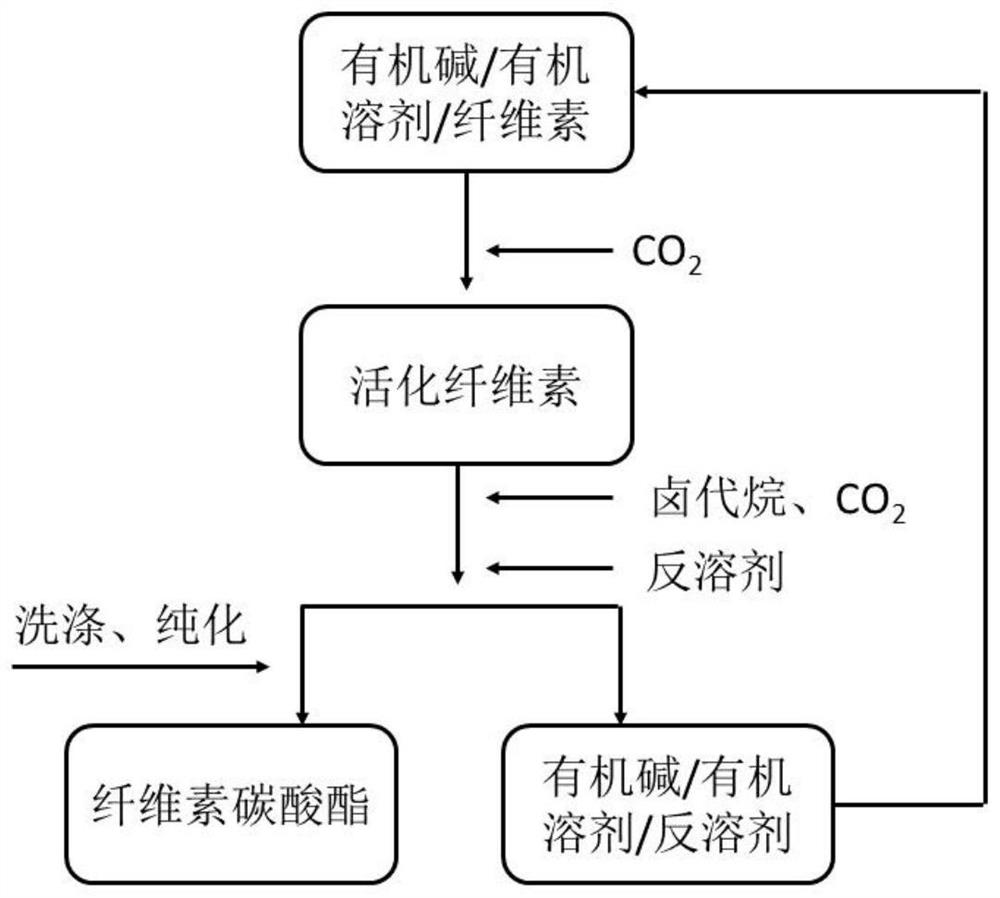

Method used

Image

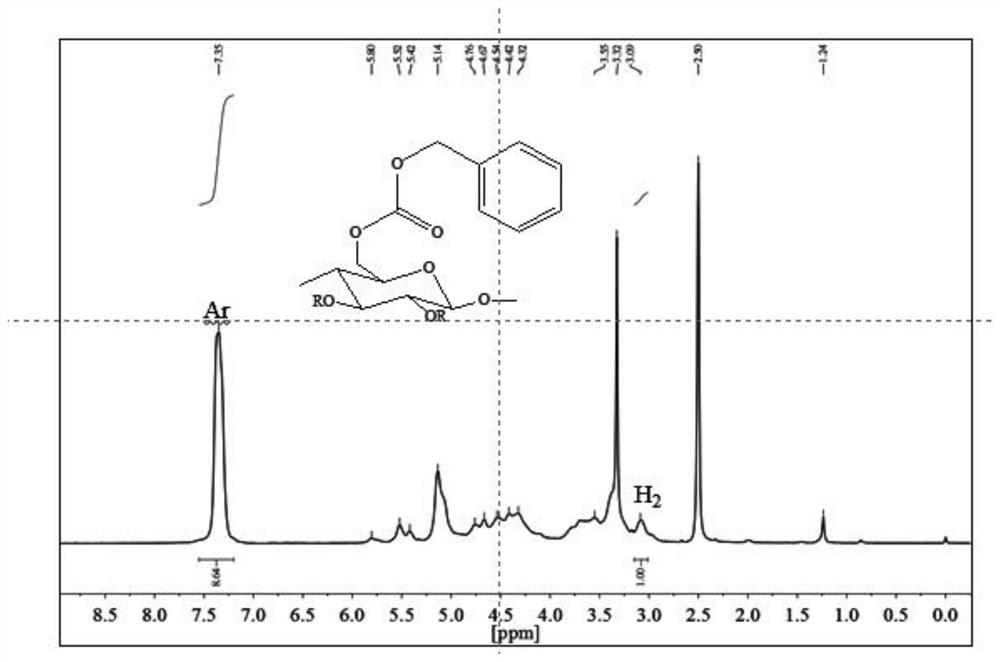

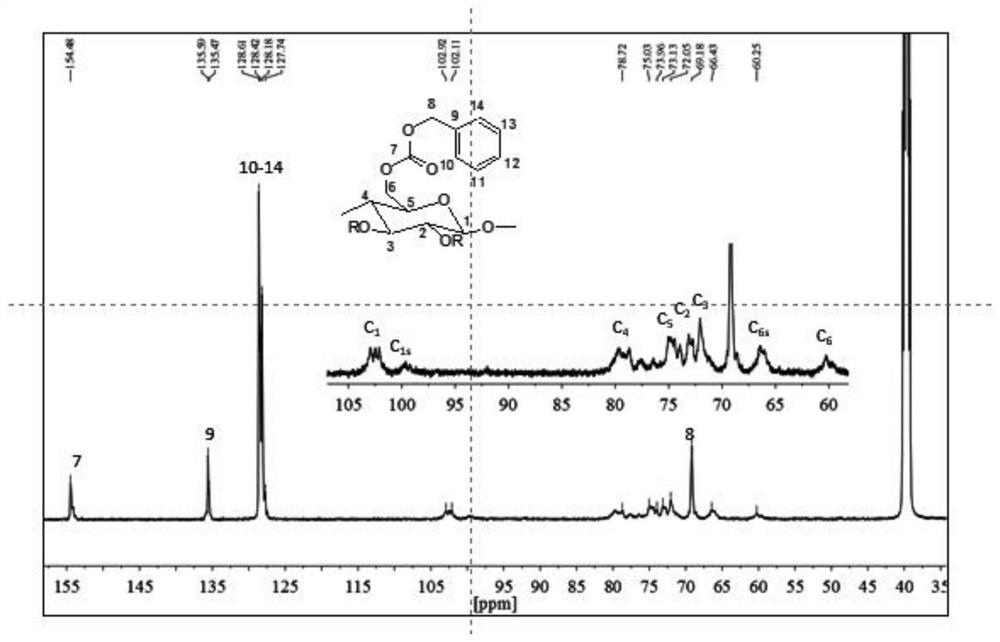

Examples

Embodiment 1

[0154] Embodiment 1: a kind of synthetic method of cellulose carbonate material, comprises the steps:

[0155] 1) The cellulose content is 30%, the structural formula is Wherein x=50 microcrystalline cellulose, structural formula is The organic base and dimethyl sulfoxide are mixed to obtain product A, wherein the mass concentration of cellulose is 2%, and the mass concentration of dimethyl sulfoxide is 0.5%;

[0156] 2) Put product A into a closed environment and fill it with carbon dioxide, so that the pressure in the closed environment is 0.1MPa, and then react at 30°C for 24 hours to generate cellulose-based CO 2 Reversible ionic liquid compound, product B;

[0157] 3) Add cellulose-based CO to product B 2 The molecular formula of the reversible ionic liquid compound with a molar ratio of 0.1:1 is IC 10 h 21 Saturated halogenated alkanes, at 0.1MPa CO 2 atmosphere, 10 oC Down reaction 48 hours, obtain C product;

[0158] 4) Add water with a volume ratio of 0.5:1 ...

Embodiment 2

[0160] Embodiment 2: a kind of synthetic method of cellulose carbonate material, comprises the steps:

[0161] 1) The cellulose content is 50%, the structural formula is Wherein the plant cellulose isolated in the cotton of x=400, structural formula is where R 1 is an alkyl group with 5 carbon atoms, R 2 , R 3 , R 4 The organic base that is methyl is mixed with tetramethylurea to obtain product A, wherein the mass concentration of cellulose is 7%, and the mass concentration of tetramethylurea is 15%;

[0162] 2) Put product A into a closed environment and fill it with carbon dioxide, so that the pressure in the closed environment is 3MPa, and then react at 50°C for 19h to generate cellulose-based CO 2 Reversible ionic liquid compound, product B;

[0163] 3) Add cellulose-based CO to product B 2 The structural formula of the reversible ionic liquid compound with a molar ratio of 0.5:1 is , where: X=Cl, R is a proton halogenated compound, CO at 3 MPa 2 atmosphere, 30...

Embodiment 3

[0166] Embodiment 3: a kind of synthetic method of cellulose carbonate material, comprises the steps:

[0167] 1) The cellulose content is 70%, the structural formula is Wherein the plant cellulose separated in the bamboo pulp of x=800, structural formula is The organic base and N,N-diethylacetamide are mixed to obtain product A, wherein the mass concentration of cellulose is 15%, and the mass concentration of N,N-diethylacetamide is 30%;

[0168] 2) Put product A into a closed environment and fill it with carbon dioxide, so that the pressure in the closed environment is 5MPa, and then react at 60°C for 12 hours to generate cellulose-based CO 2 Reversible ionic liquid compound, product B;

[0169] 3) Add cellulose-based CO to product B 2 The structural formula of the reversible ionic liquid compound with a molar ratio of 1:1 is , where: X=Br; R is a n-propyl halogenated compound, in 6MPa of CO 2 atmosphere, 70 oC Down reaction 25 hours, obtain C product;

[0170] 4) Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com