A method for simultaneous measurement of stress and displacement in saturated granular media based on transparent photoelastic materials

A photoelastic particle and particle medium technology, applied in the field of pore liquid, digital image correlation technology to measure the internal stress of particles and particle displacement, which can solve the problem that there is no better method, it is difficult to popularize and apply, and it is difficult to measure the stress and displacement of granular materials, etc. problems and reduce the cost of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

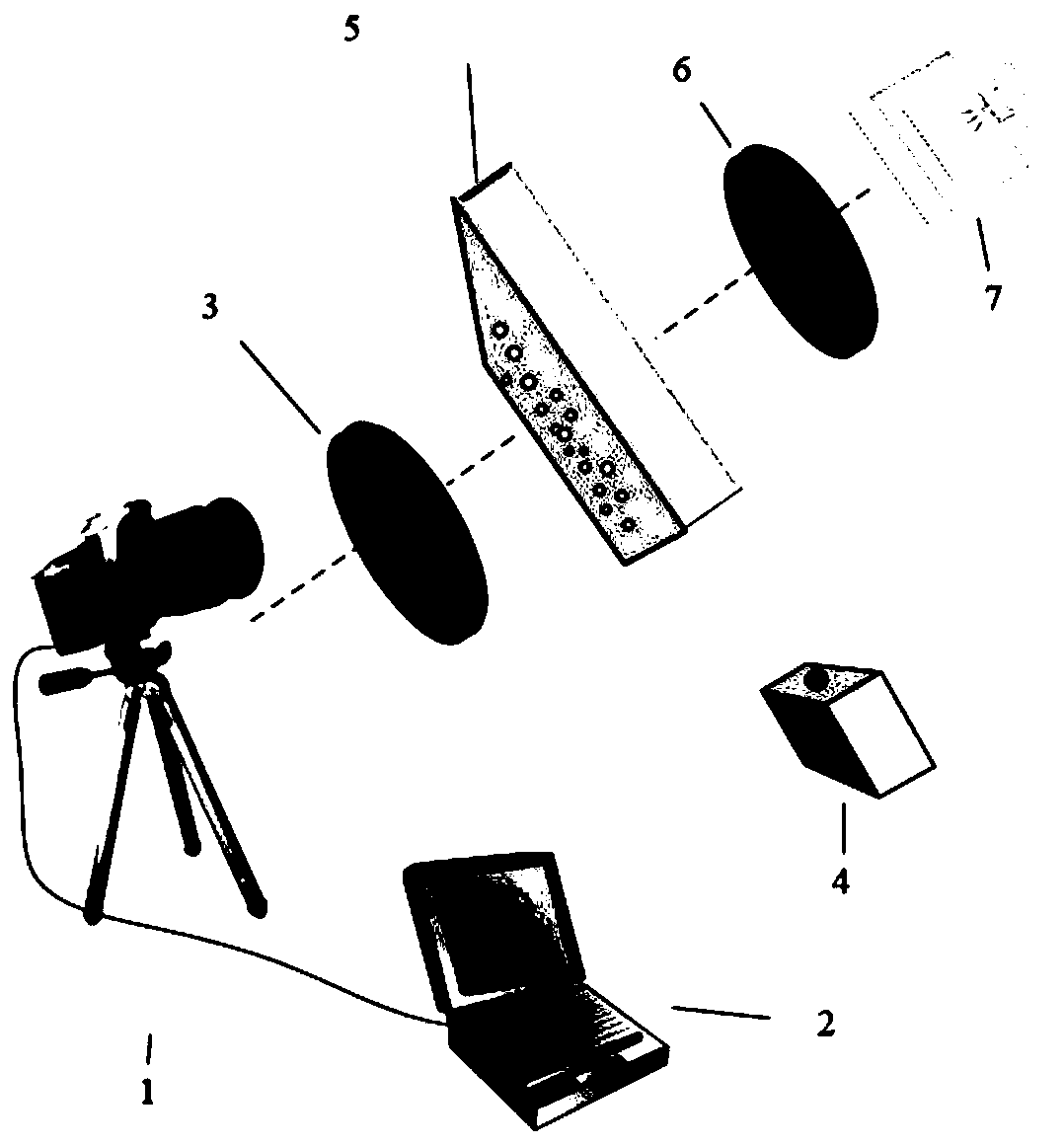

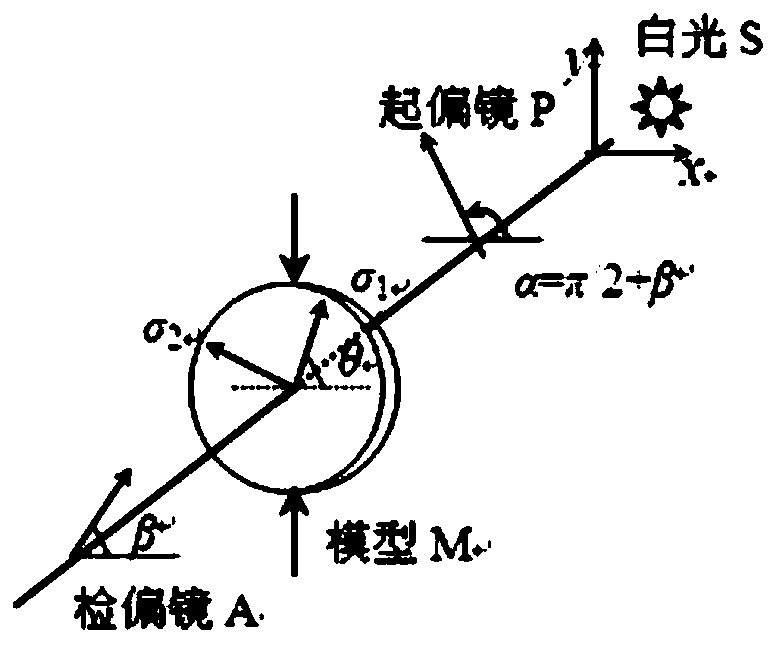

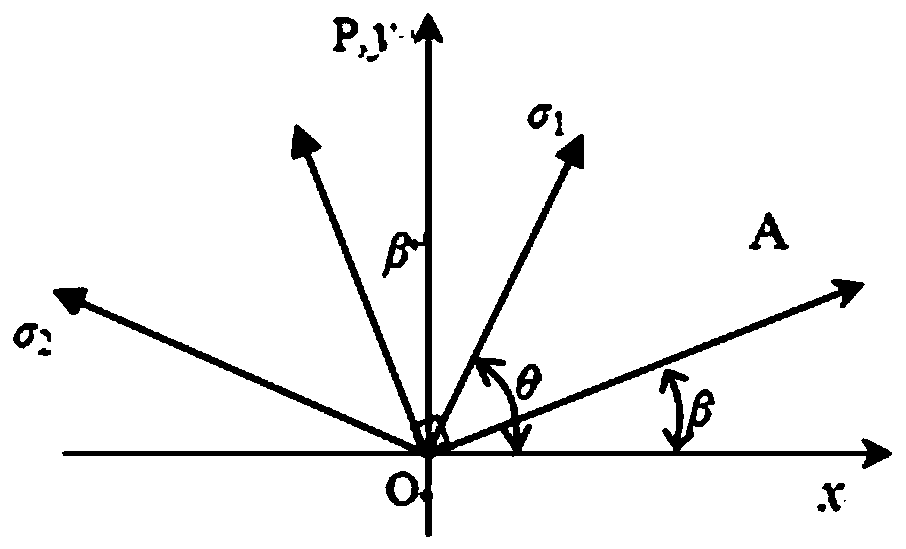

[0022] A method for measuring the internal stress and displacement of saturated granular materials based on transparent photoelastic granular materials, consisting of artificially configured saturated transparent photoelastic granular medium materials, laser generators and lenses placed on the side, loading control devices, digital cameras, and interpolated images The acquisition card is composed of a PC. An analysis lens 3 and a polarizing lens 6 are placed before and after the saturated transparent particle model sample, and a light source 7 is placed behind the polarizing lens.

[0023] The laser provides a continuous laser light source, which generates a fan-shaped laser through a cylindrical lens, and produces a laser speckle effect after entering the transparent photoelastic particle model. The exter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com