Easy-to-operate hollow sand cylinder sample preparation device and method

A technology for hollow cylindrical samples and sandy soil, which is applied in sample preparation devices and the field of sample preparation, can solve the problems of large layer thickness, obvious difference between layers, and easy inclination, etc., achieve smooth and uniform surface, simplify sample preparation process, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

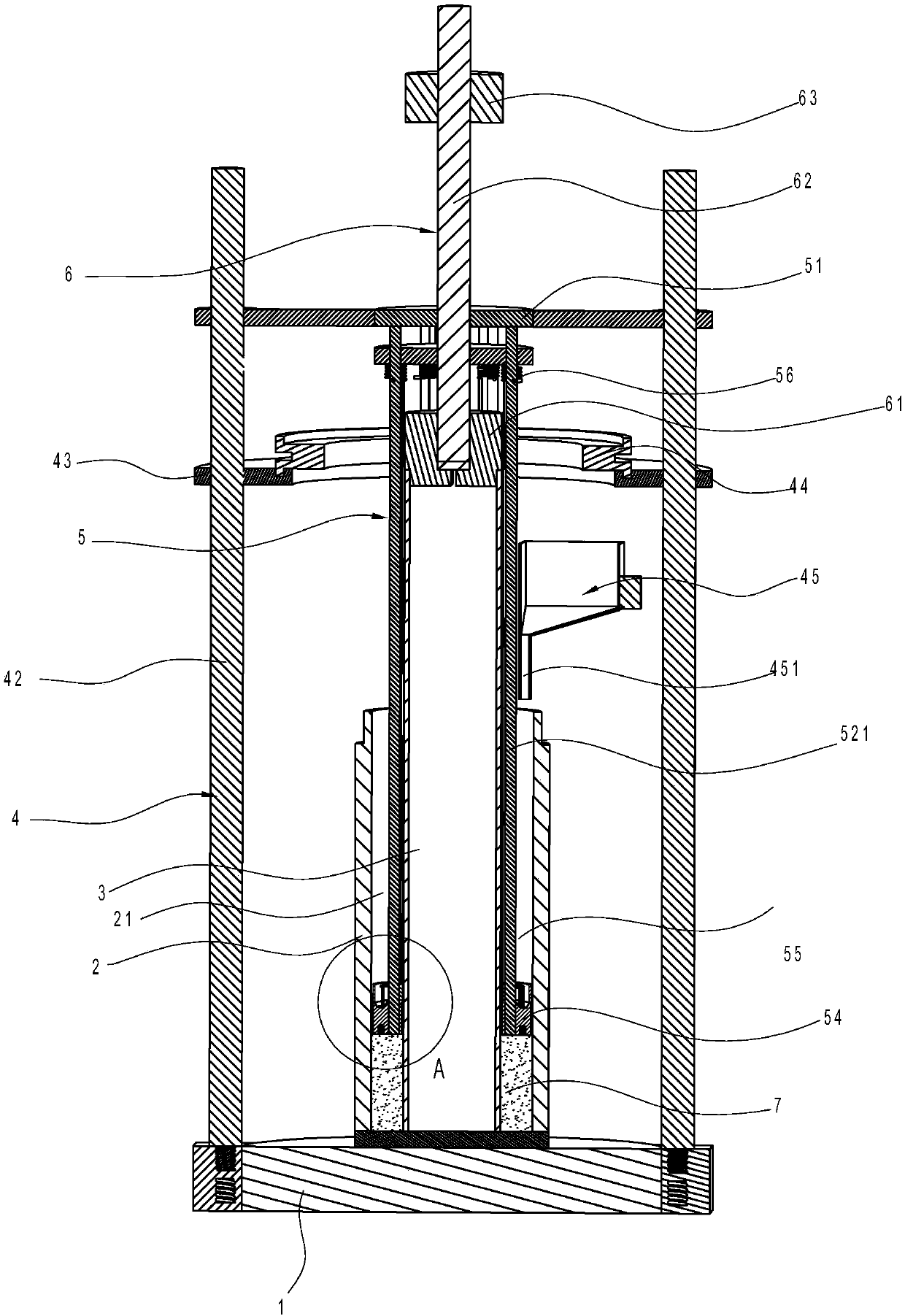

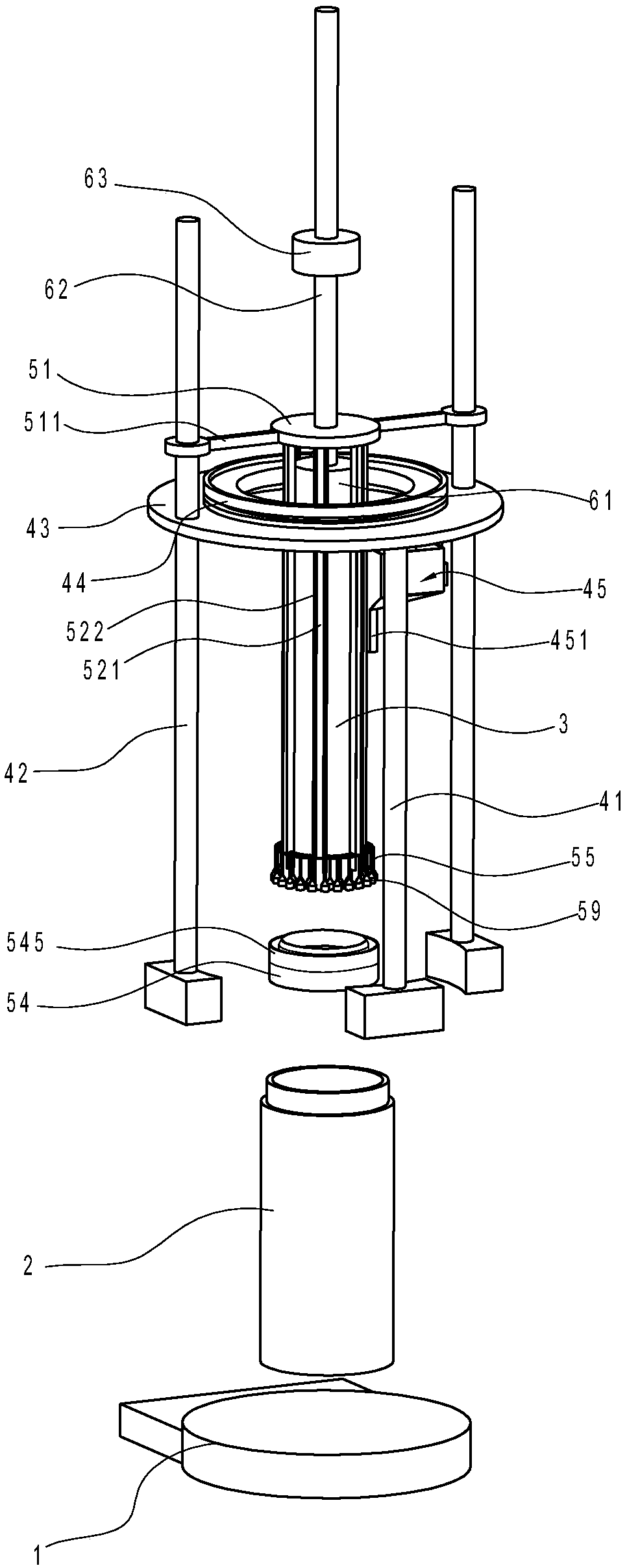

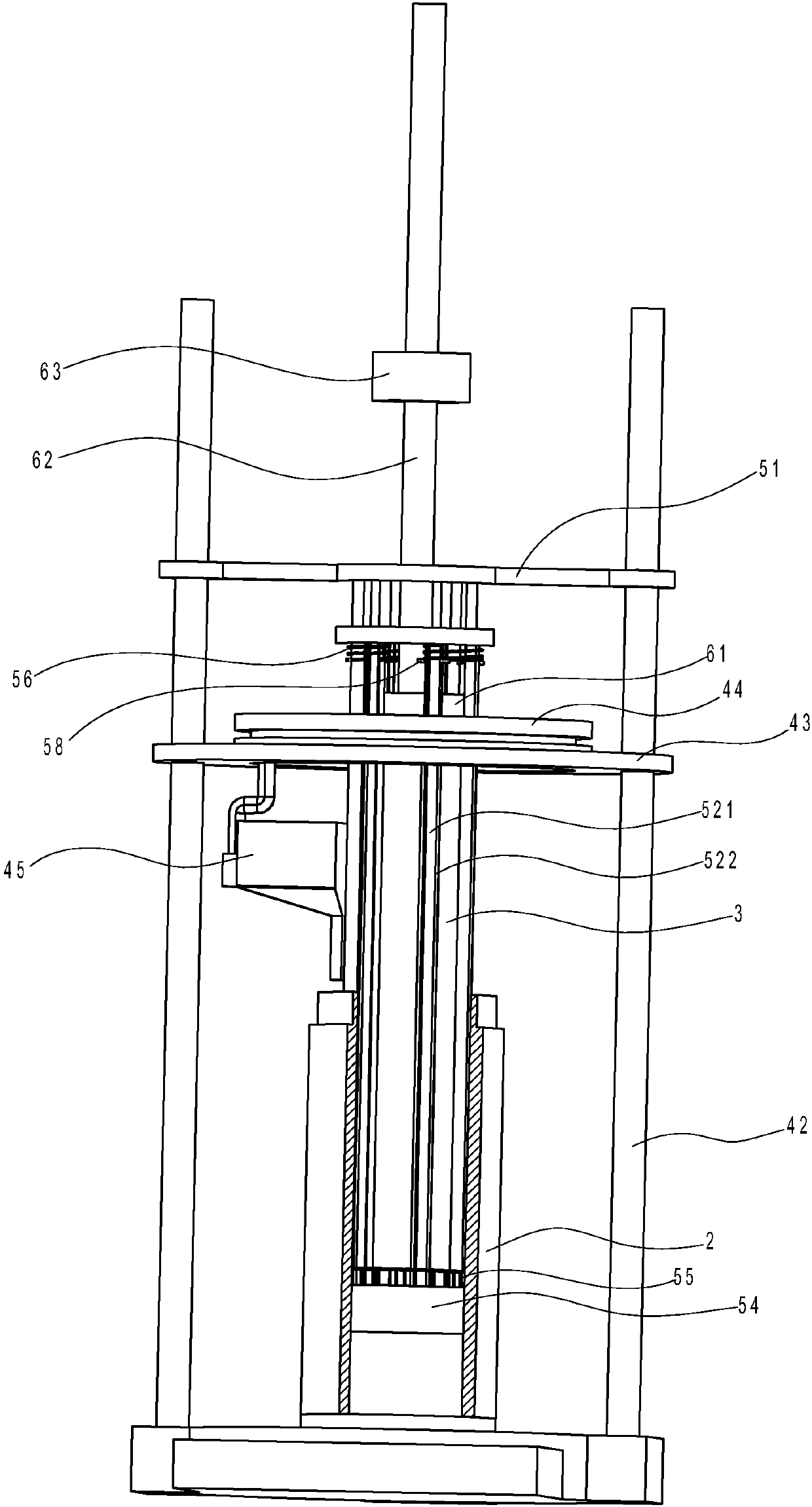

[0032] Such as Figures 1 to 8As shown, the easy-to-operate hollow cylindrical sample preparation device for sand and soil in this implementation includes a base 1 , an outer mold 2 , an inner mold 3 , a blanking assembly 4 , an unloading compaction assembly 5 and a tamping assembly 6 .

[0033] Wherein, the outer mold 2 is composed of three-lobed circular stainless steel metal sheets with a central angle of 120° of a certain thickness, and is fixed by upper and lower clamping rings. The inner mold 3 is composed of two semicircular stainless steel cylinders and a stainless steel pumping plate butt joint. The bottom ends of the outer mold 2 and the inner mold 3 are embedded in the annular shallow groove on the top surface of the base 1 . The inner mold 3 is arranged in the outer mold 2 , and a sample cavity 21 for forming a sample is formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com