Detection tool for detecting pressure transducer

A technology for detecting tooling and pressure, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of rubber tube damage, waste of rubber tube, etc., to achieve convenient placement and fixation, optimized sealing effect, fast multi-station measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

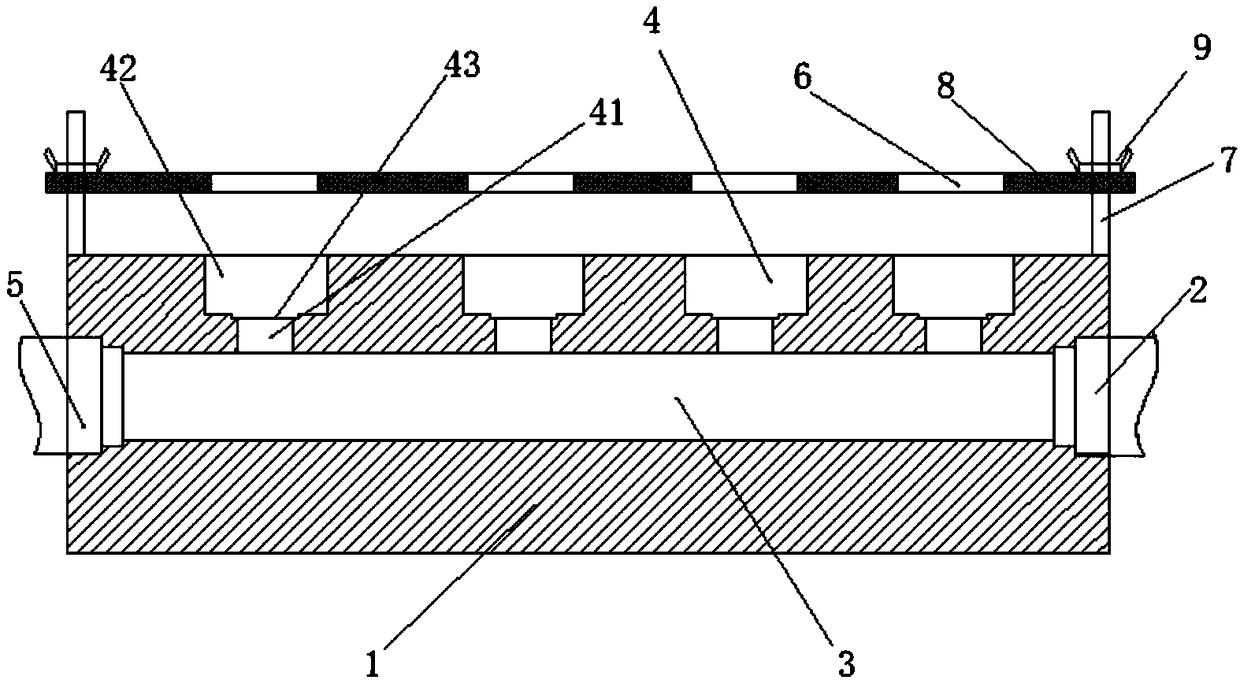

[0022] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

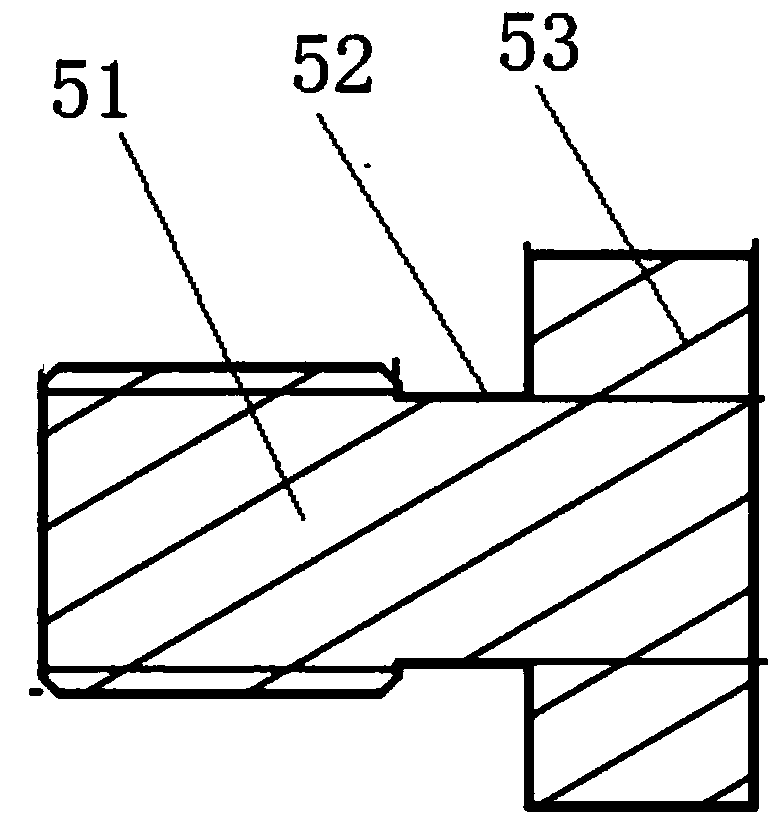

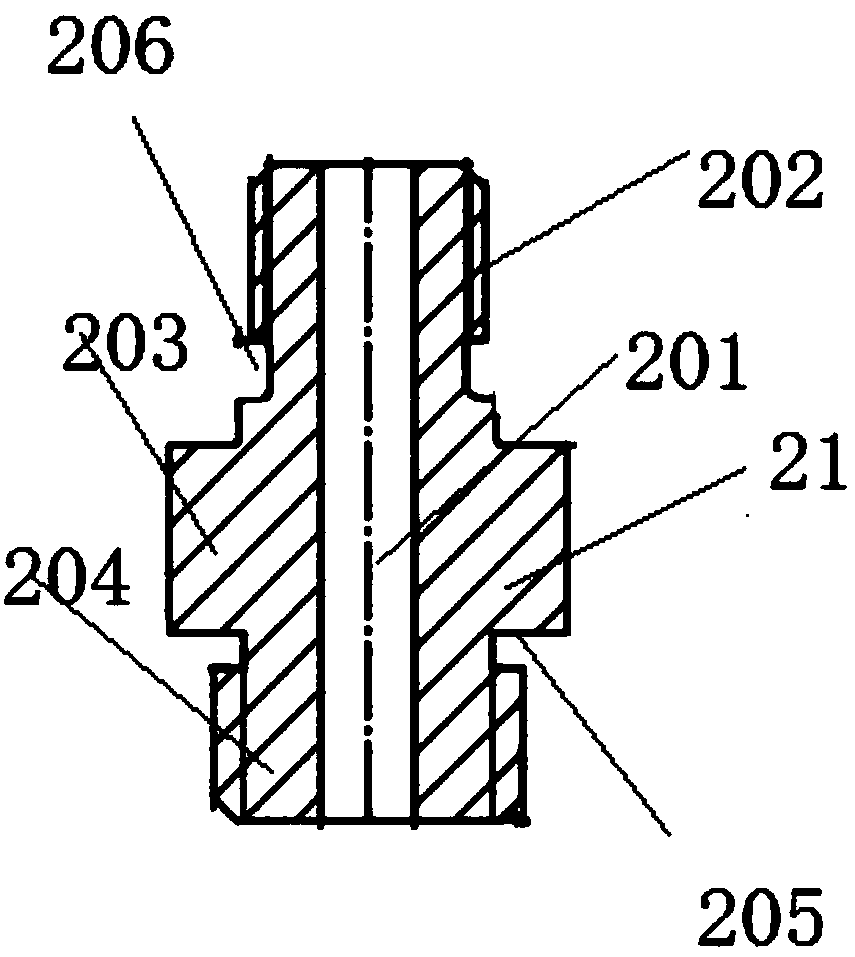

[0023] A detection tool for detecting a pressure sensor, the detection tool includes a detection base 1, a mainstream channel 3 for gas circulation is provided in the detection base 1, and at least one placement groove 4 for placing a sensor is provided on the detection base 1, each Each placement groove 4 is all communicated with the main flow channel 3, and the end of the main flow channel 3 is connected with an air intake assembly; the air intake assembly disclosed by the present invention is a known technology, as long as all air supply equipment that can provide air intake for the present invention are all Yes, it is well known to those skilled in the art, and will not be repeated here; at the same time, one of the purposes of the present invention is to change the connection mode of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com