Lighting method for LED illumination light guide plate

A technology of LED lighting and LED light source, which is applied to the light guides of lighting devices, light guides of lighting systems, components of lighting devices, etc. Good uniformity of brightness, improved light distribution efficiency and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

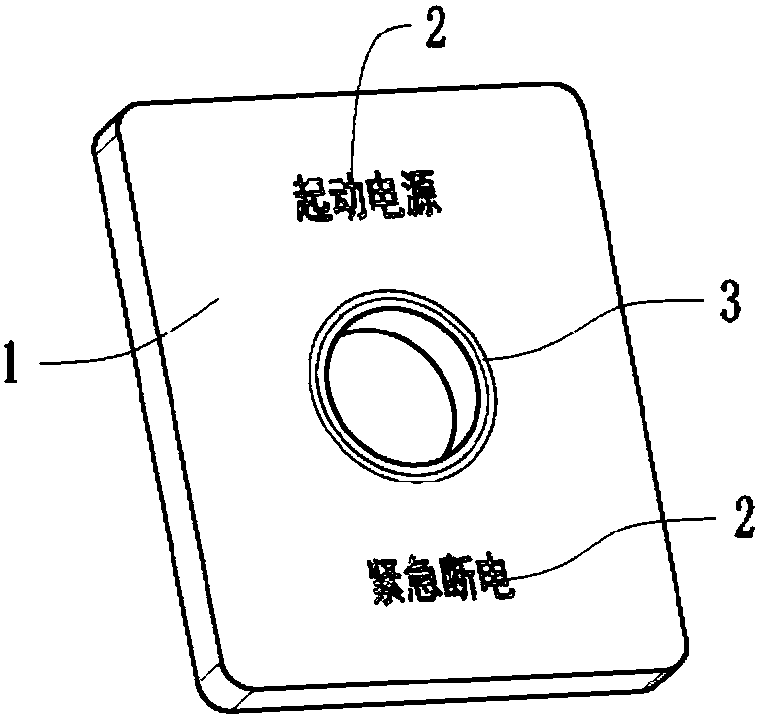

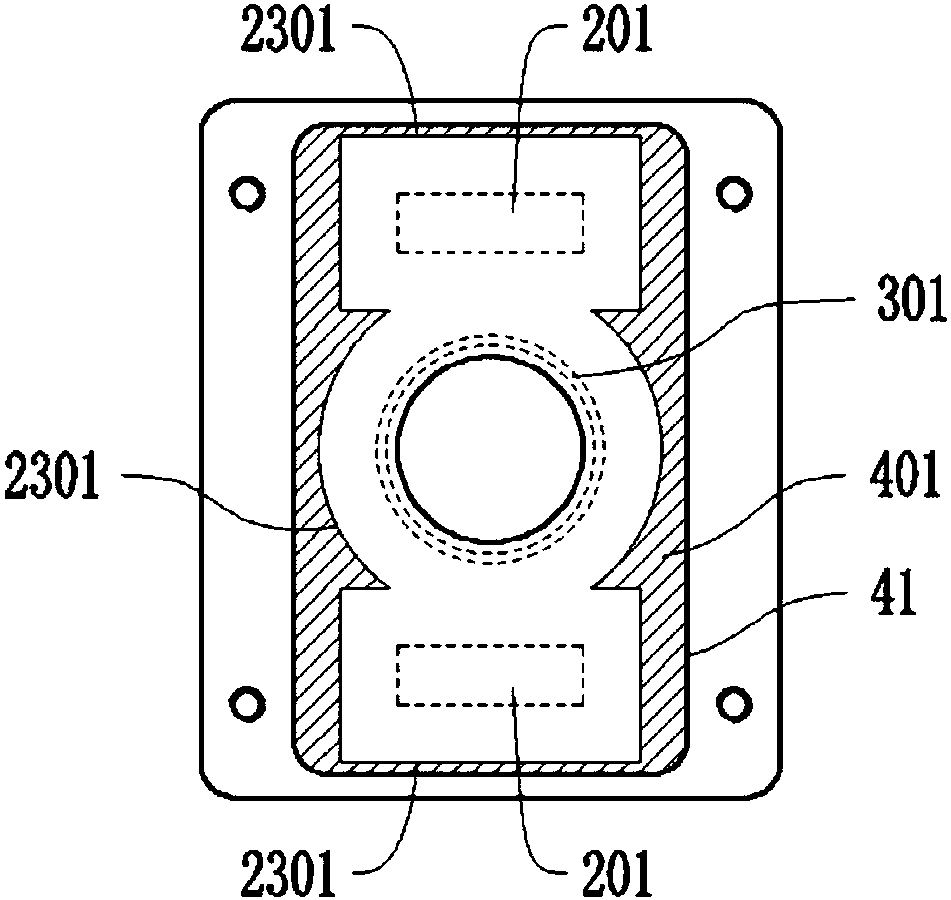

[0019] This see Figure 1 to Figure 6 , shown in the figure is a specific embodiment of a light distribution structure and method for an LED lighting light guide plate, including a light guide panel 1 , characters 2 , engraved lines 3 and a sunken surface area 4 . Wherein, the characters 2 and the engraved lines 3 are placed on the front of the light guide panel 1, and the characters 2 and the engraved lines 3 need to emit light; The back of the panel 1 is used for accommodating the light source circuit board. The present invention is characterized in that the following lighting steps are performed in sequence:

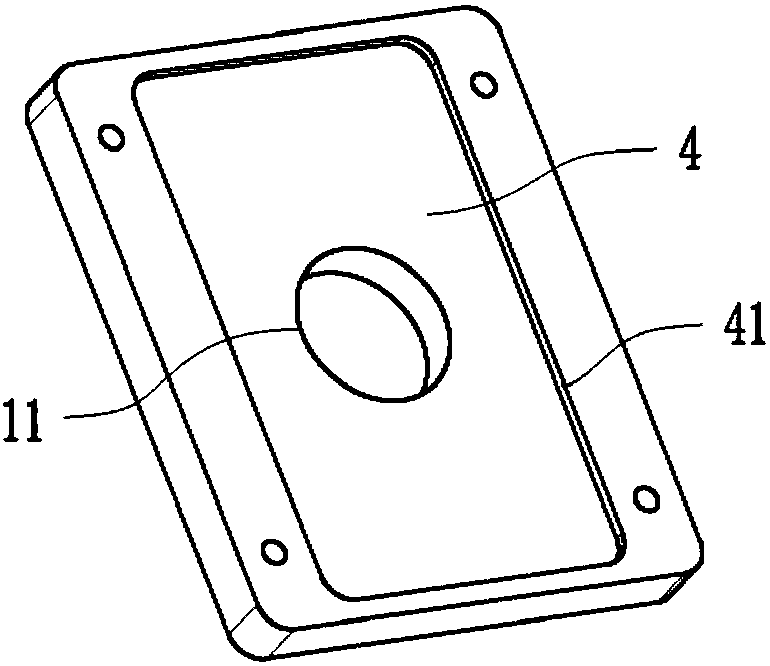

[0020] Step 1. According to the back structure of the light guide panel 1, the inner contour line 11 and the outer contour line 41 are formed by shape offset, and the area included by the inner contour line 11 and the outer contour line 41 is for accommodating light sources plate sink area 4, see figure 2 ;

[0021] Step 2: In the sunken surface area 4, obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com