Micro normally closed electromagnetic valve with two-stage gag bit structures

A technology of normally closed solenoid valve and solenoid valve, which is applied in valve details, valve device, valve operation/release device, etc., can solve the problem of miniature solenoid valve relying on imports, etc., to improve product opening electromagnetic force and reduce product opening voltage. , the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

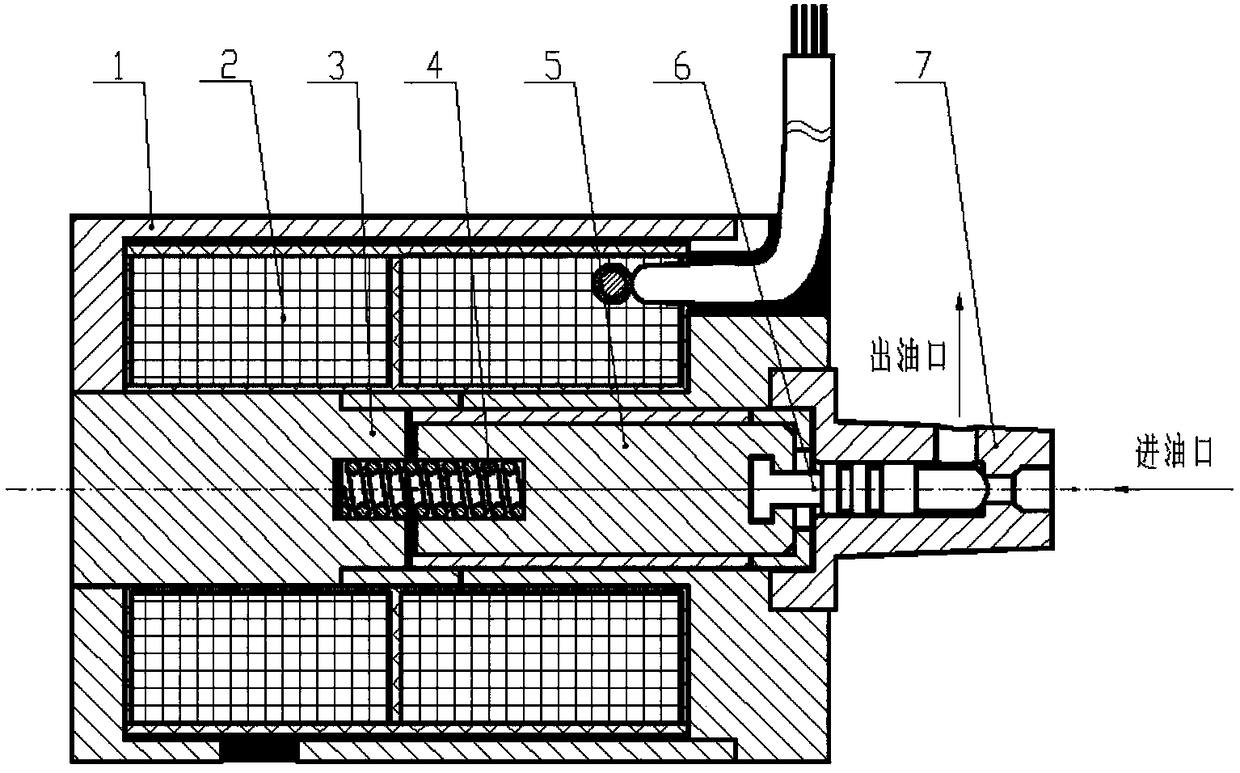

[0026] see Figure 1-Figure 4 : The present invention is mainly made up of coil cover 1, coil 2, pole shoe assembly 3, spring 4, armature assembly 5, ejector rod 6 and valve body 7.

[0027] During the assembly process, the coil 2 and the coil cover 1 are successively put on the pole shoe assembly 3, and the right end of the coil cover 1 and the pole shoe assembly 3 are welded and fixed; then the ejector rod 6 is installed into the armature assembly 3 and then together with the spring 4 Press into the pole shoe assembly 3, and finally press the valve body 7 into the pole shoe assembly 3, after the left end of the valve body 7 and the pole shoe assembly 3 are welded and fixed, the assembly of the entire valve assembly is completed.

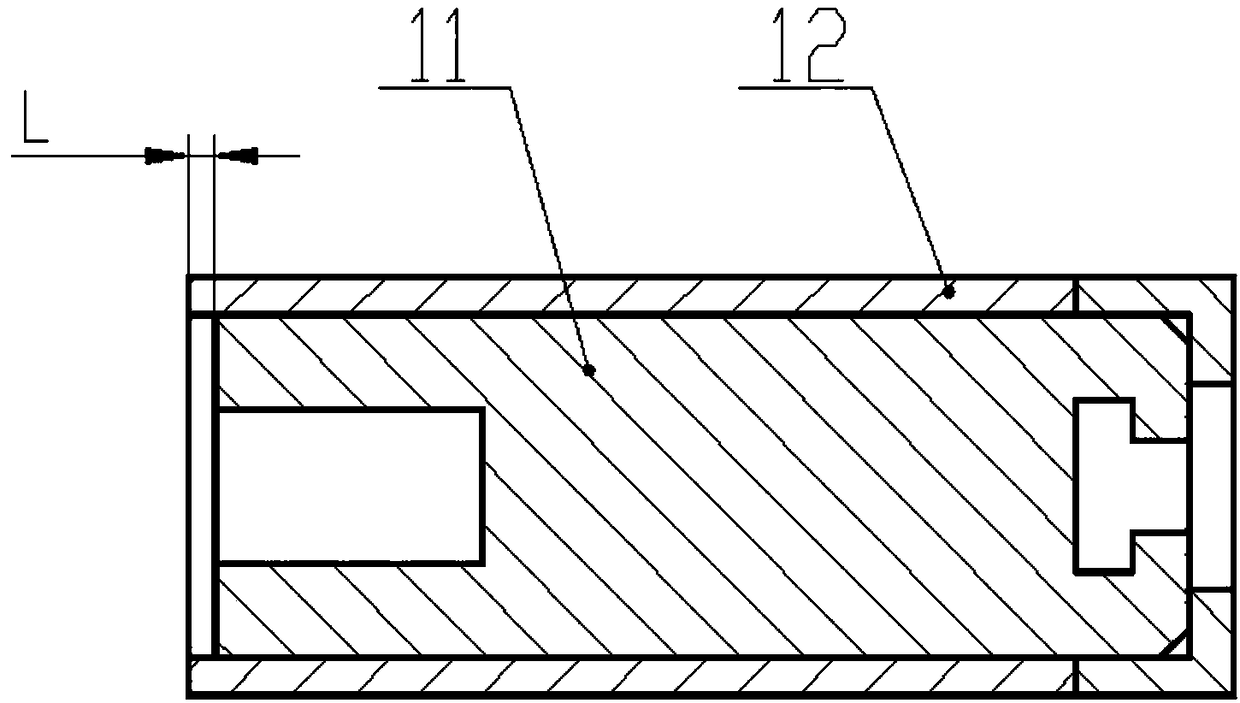

[0028] Such as figure 2 As shown, the pole shoe assembly 3 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com