Power rotation-angle output case capable of achieving positive and negative rotation

A forward and reverse, output box technology, applied in the direction of transmission components, transmission devices, transportation and packaging, etc., can solve the problems of many forward gears, unfavorable overall layout, high manufacturing cost, etc., to achieve front and rear double power output, easy to be independent Shifting operation, the effect of meeting the needs of multi-purpose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

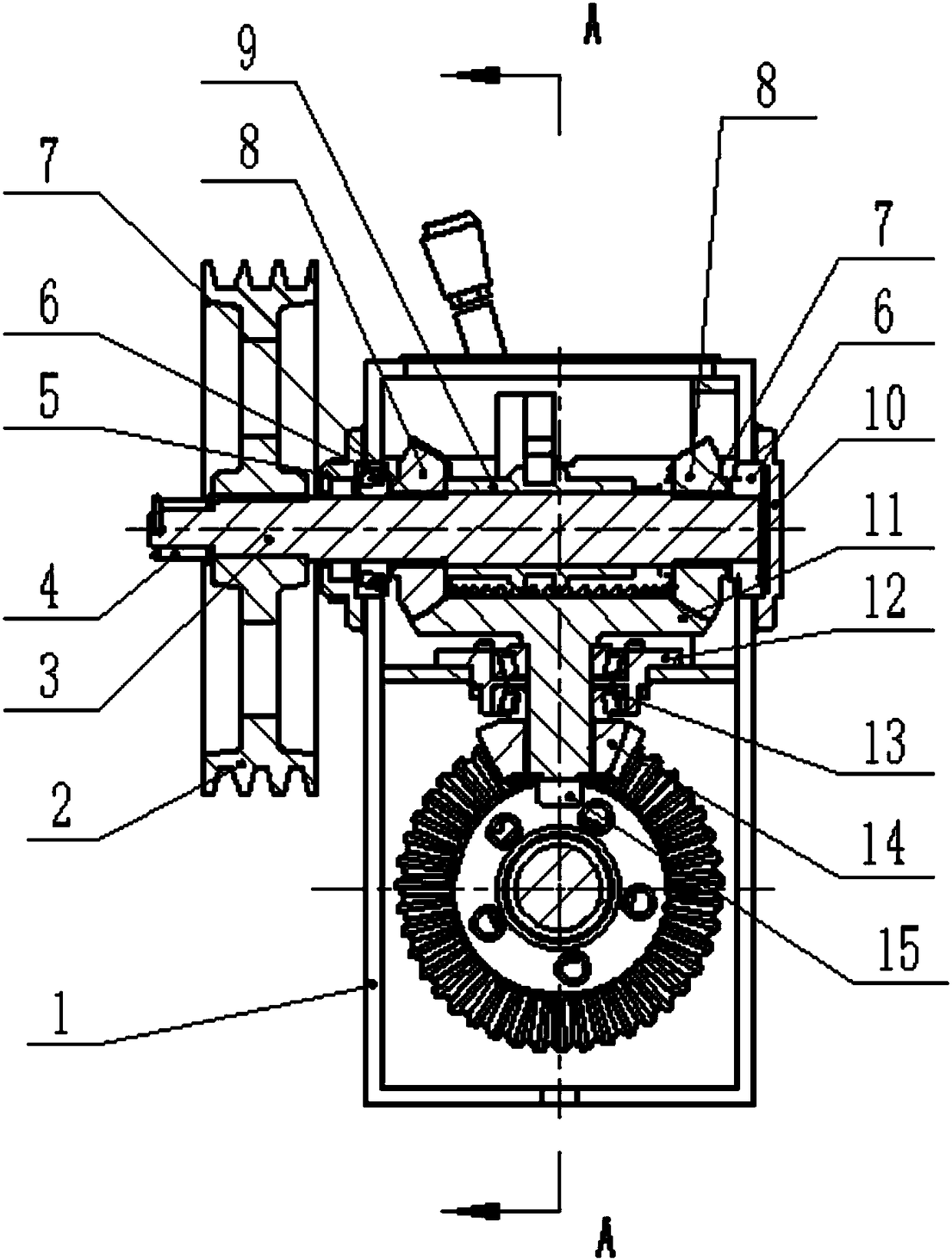

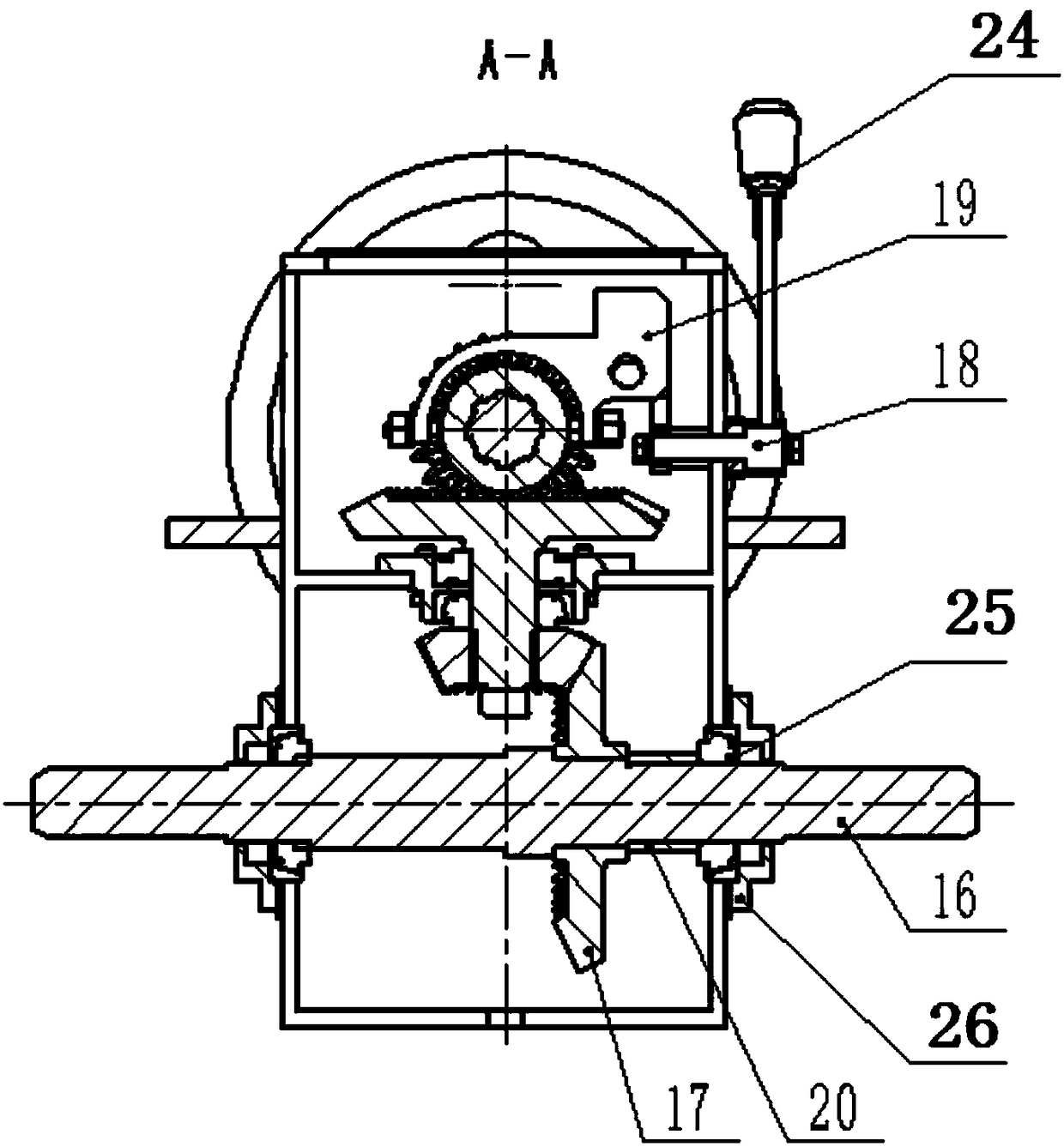

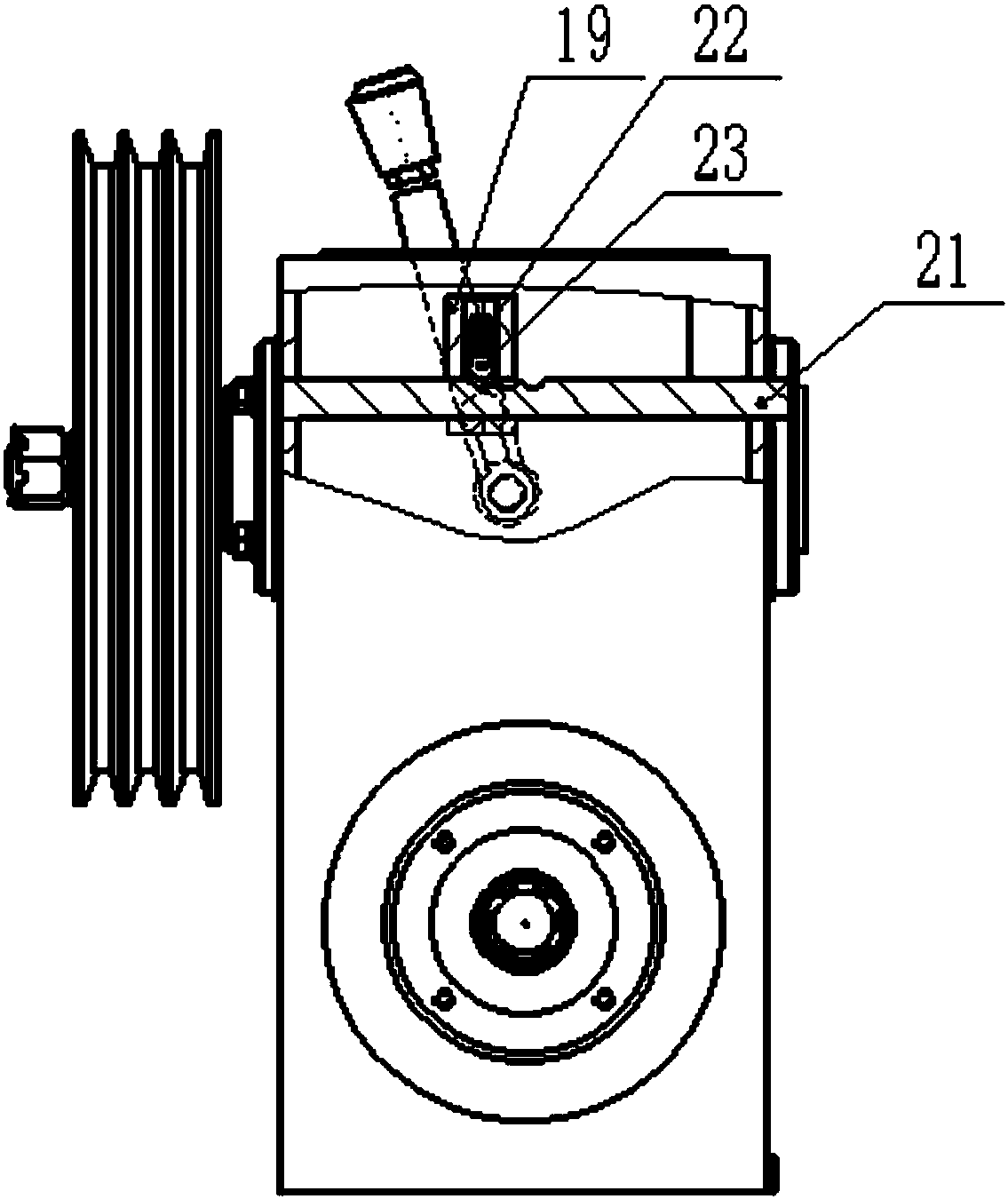

[0018] As shown in the drawings, the present invention realizes the forward and reverse power angle output box, which includes a box body 1 and a clutch 2. There are input shafts 3 and output shafts 16 arranged in a cross in the box body 1, and the input shaft 3 is on the top. , the output shaft 16 is below. The two ends of input shaft 3 are installed on the box body 1 by bearing one 6, and bearing cover one 5 is installed on the outside of bearing one 6 on the left side, and bearing cover two 10 is installed on the outside of bearing one 6 on the right side; End is installed on the casing 1 by bearing three 25 respectively, and the outside of bearing three 25 is equipped with bearing cover three 26. In the inner cavity of the box body 1, the middle part of the input shaft 3 is connected with a shift sliding sleeve 9 that can move left and right through a spline, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com