Multi-seal ultrahigh pressure oil way filter

A filter and ultra-high pressure technology, used in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as affecting hydraulic pressure, destroying hydraulic oil pressure, leakage pressure, etc., to ensure oil Road pressure, improve sealing performance, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

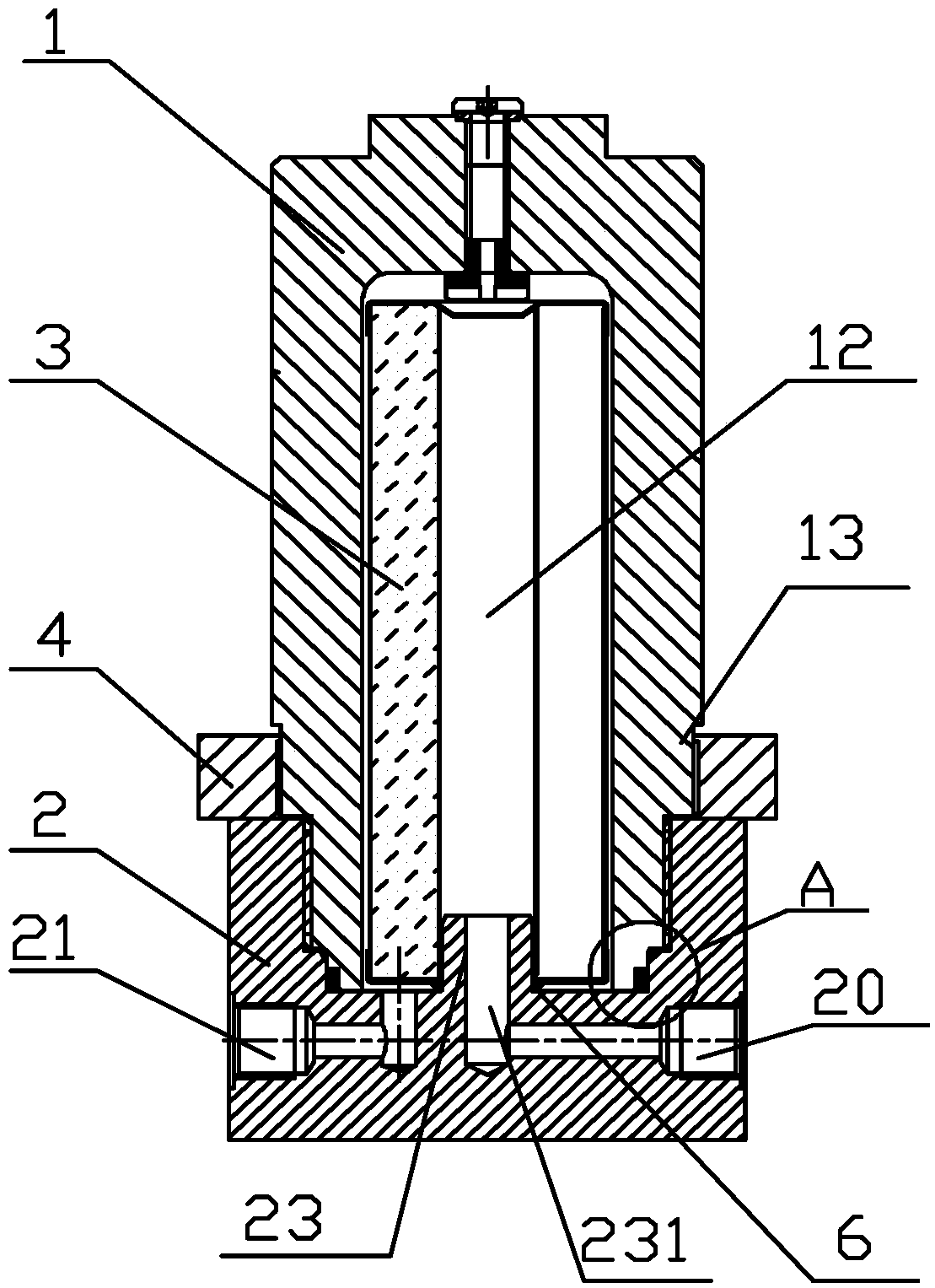

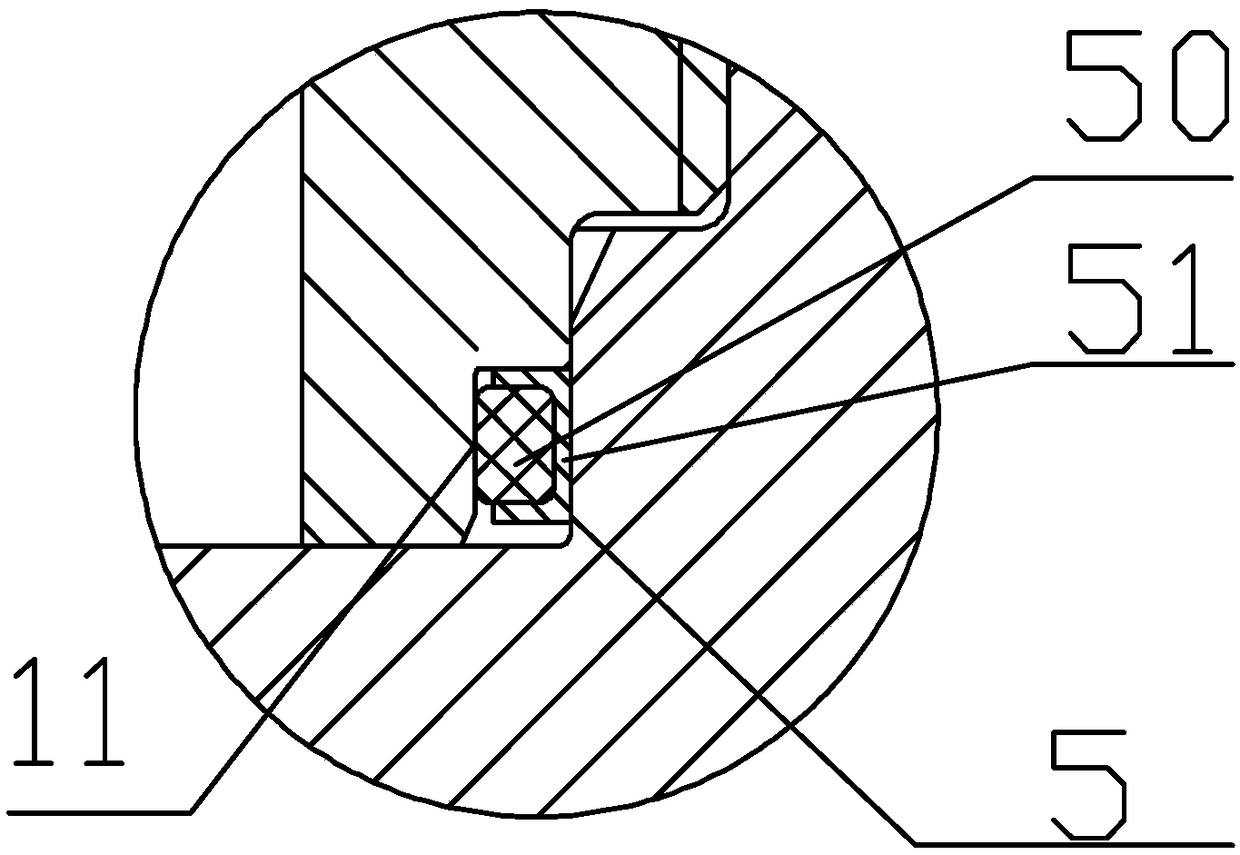

[0015] refer to figure 1 and 2 The multi-seal ultra-high pressure oil circuit filter shown includes a filter cartridge 1, a filter seat 2 and a filter element 3. The filter seat 2 is concave, with its notch facing upwards. The filter seat 2 is provided with Oil inlet 20 and oil outlet 21, the filter cartridge 1 is fastened in the notch of the filter seat 2, and fixed by threaded connection, the filter cartridge 1 is at the bottom of the threaded section of the filter seat 2 There is a step 11, the step 11 is introverted, and a closed annular space is formed between the step 11 and the inner side wall and the bottom wall of the filter seat 2, and a slip ring seal assembly 5 for holes is installed in the annular space. The slip ring seal combination 5 includes a U-shaped sealing ring 51 and a square sealing ring 50 matching it. The sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com