Plunger part of high pressure plunger type hydraulic pump

A hydraulic pump and plunger technology, applied in the hydraulic field, can solve the problems of short service life, poor high pressure effect, and large friction, and achieve the effect of improving service life, increasing stability and reducing closing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

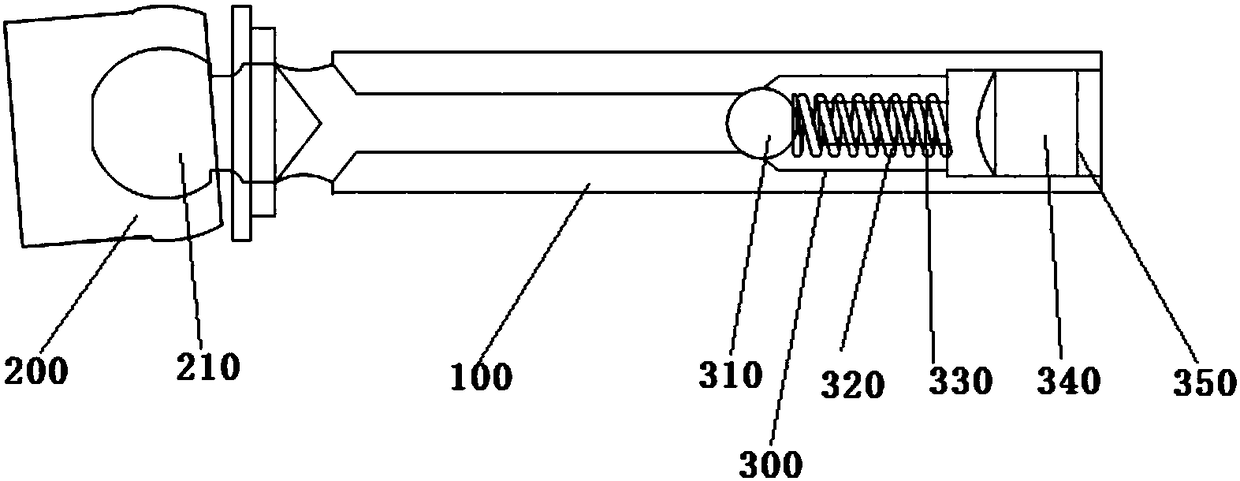

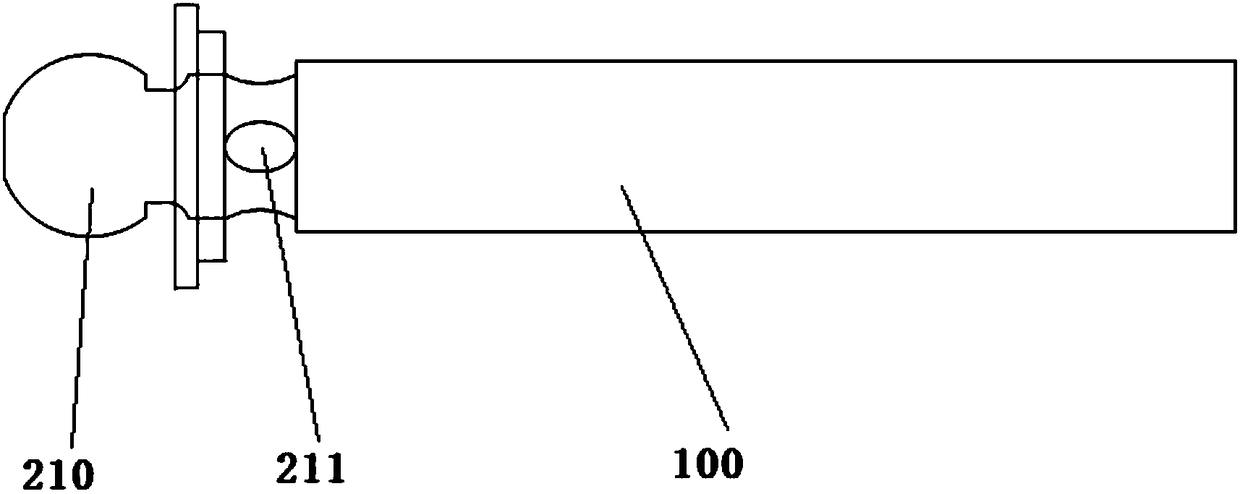

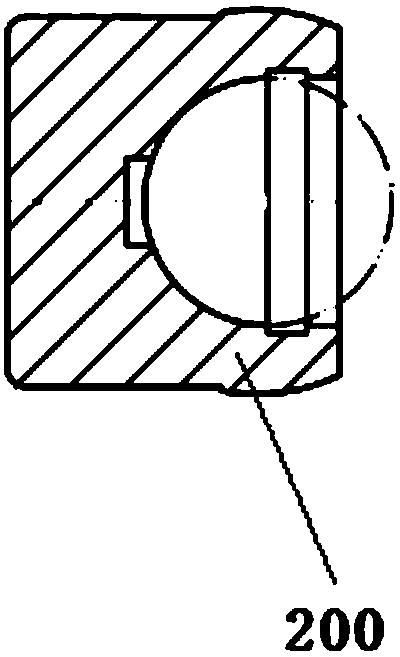

[0022] Such as figure 1 As shown, a plunger component 500 of a high-pressure plunger hydraulic pump includes a plunger body 100 and a slide shoe 200 connected to the front end of the plunger body 100, and the bottom end of the slide shoe 200 is provided with a rounded corner with a radius of 1 mm. The front end of the plunger body 100 is provided with a ball head 210 for wrapping the sliding shoe 200, and the plunger body 100 is provided with a cavity for hydraulic oil flow. Such as figure 2 As shown, the plunger body 100 behind the ball head 210 is provided with a through hole 211 communicating with the cavity, and a check valve 300 for ensuring the one-way flow of hydraulic oil is provided in the cavity. When the hydraulic pump is wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com