Bottom line cutting device, sewing machine and control method thereof

A control method and technology for a sewing machine, which are applied to a ferrule mechanism for a sewing machine, a mechanism for cutting threads in a sewing machine, and sewing machine components, etc., can solve the problems of high labor cost, high time cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

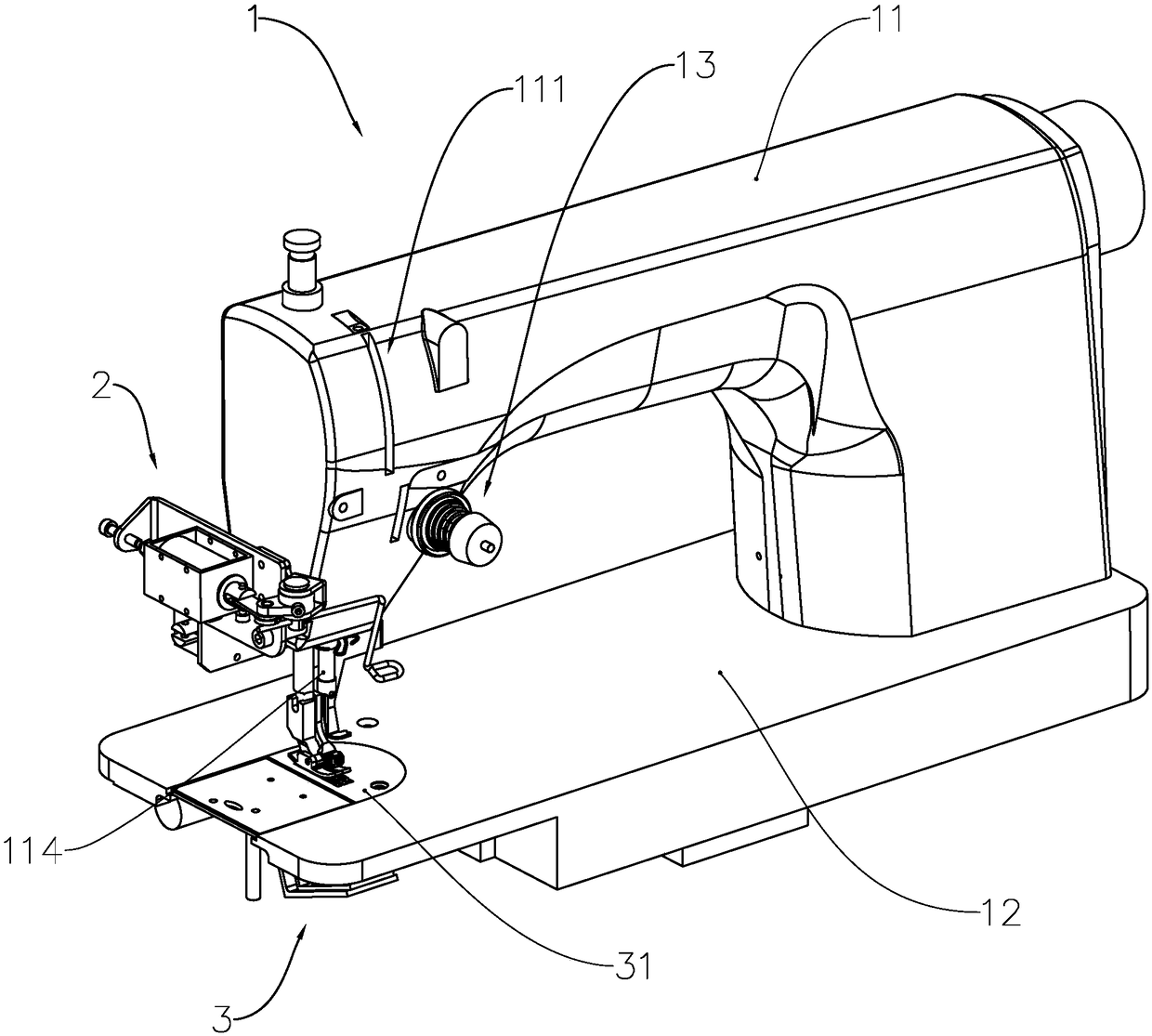

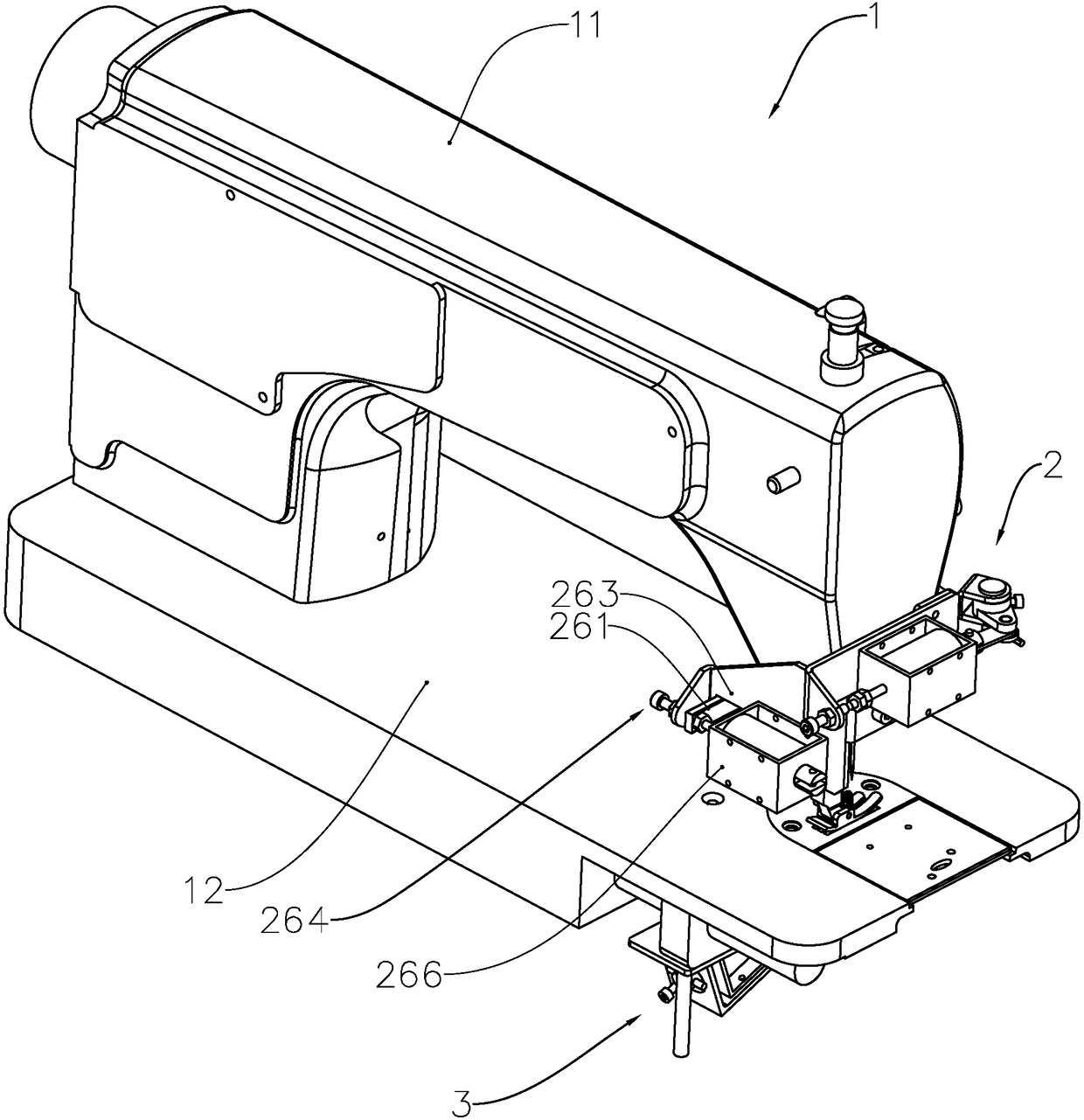

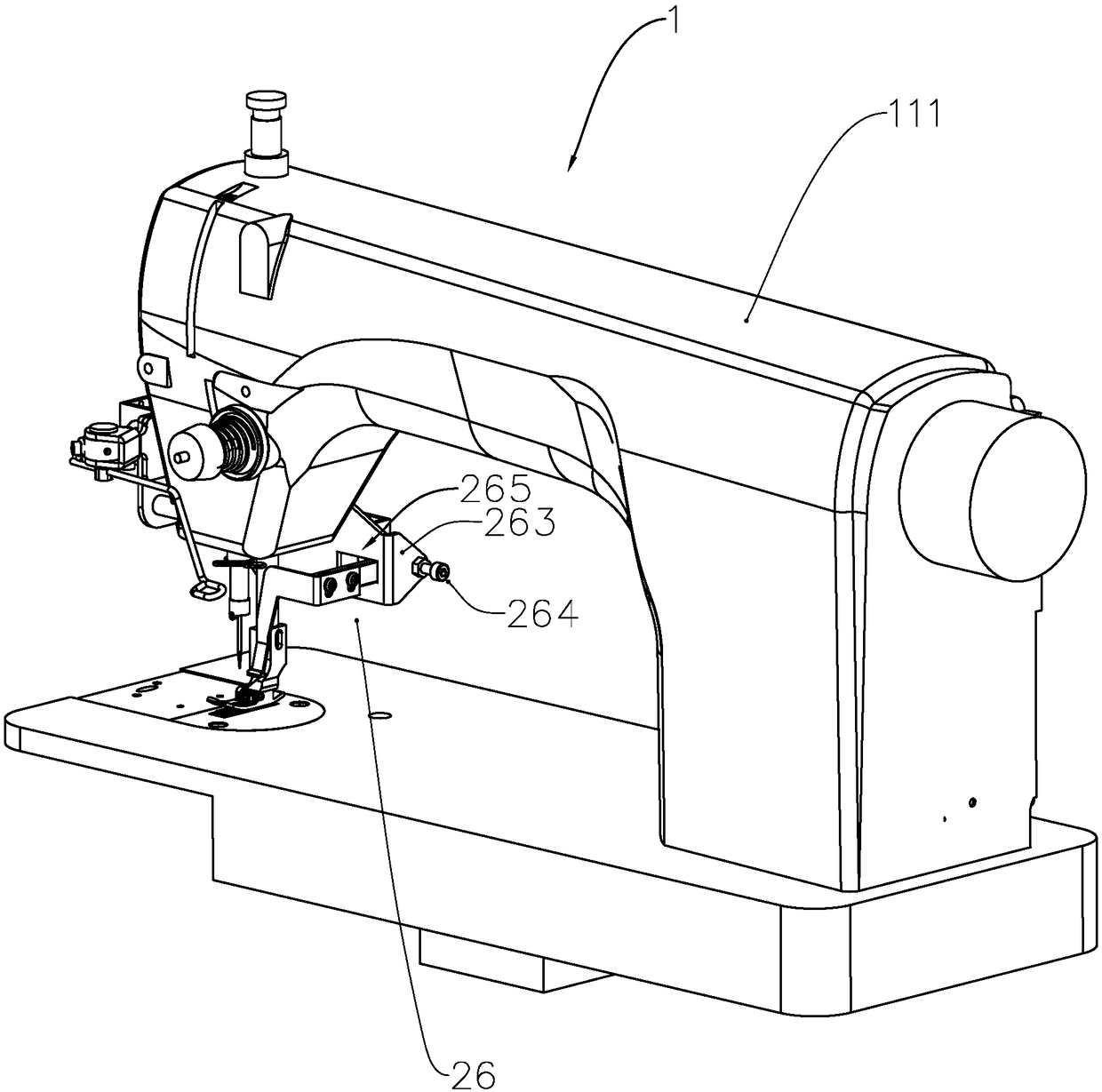

[0050] refer to Figure 1 to Figure 3 , the sewing machine 1 includes a machine head 11 and a machine base 12, the machine head 11 is arranged on the machine base 12, a vertical groove 111 is arranged on the machine head 11, a thread take-up rod is arranged in the groove 111, and a thread take-up rod is arranged at the bottom of the chute 111. Thread clamp 13 is arranged. The machine head 11 is also provided with a cloth presser 112 and a machine needle 114. The cloth presser 112 is provided with a needle position 113 through the through hole. The needle position is the space for the machine needle to run. Above, it is the upper needle position, the lowest running point of the machine needle is below the needle plate, which is the lower needle position, the needle moves back and forth between the upper needle position and the lower needle position for sewing, and the needle 114 is used to The needle position 113 of the cloth presser 112 moves back and forth. The machine head...

no. 2 example

[0078] The second embodiment is mainly to improve the cutting surface thread device 4, refer to Figure 14 to Figure 16 , The thread cutting device 4 includes a thread cutting device, a thread loosening device, a thread sweeping device and a support 41. The support 41 is arranged on the side of the sewing machine, and the thread releasing device in the above-mentioned embodiment is arranged on the support 41.

[0079] The wire-sweeping device is arranged on the bracket 41, and the wire-sweeping device includes a wire-sweeping driving device 43, a wire-sweeping bracket 421, a rotating bracket 423, a connecting bracket 424, a swinging bracket 425, a limiting bracket 426, an installation bracket 441 and a limiting column 444, The mounting bracket 441 is horizontally installed on the bracket 41, the bracket 41 is provided with an overhanging hinged part 411 on the lower side, and the wire sweeping drive device 43 is a rotating electromagnet, which is arranged on the mounting bracke...

no. 3 example

[0085] The third embodiment of the sewing machine mainly improves the bottom thread cutting device 5. The bottom thread cutting device 5 includes a bracket, a swing bracket 52, a connecting bracket 54 and a rotating electromagnet 51. The bracket includes a rotating bracket 55 and a bearing bracket 56. The rotating bracket and the bearing bracket and Same as above-mentioned embodiment, rotating electromagnet 51 drives swinging bracket 52 to rotate, and connecting bracket 54 is hinged between swinging bracket 52 and rotating bracket 55, is also provided with positioning column 53 on one side of swinging bracket 52, and positioning column 53 is used. Play a position-limiting effect on the swing bracket 52.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com