Ferrocenyl ruthenium metal cluster as well as preparation method and application thereof

A ferrocene ruthenium and cluster compound technology is applied in the field of ferrocene ruthenium metal cluster compound and its preparation, which can solve the problems of reducing propellant pressure index, easy volatility, easy migration and the like, and achieves increased conjugation , low vapor pressure and volatility, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

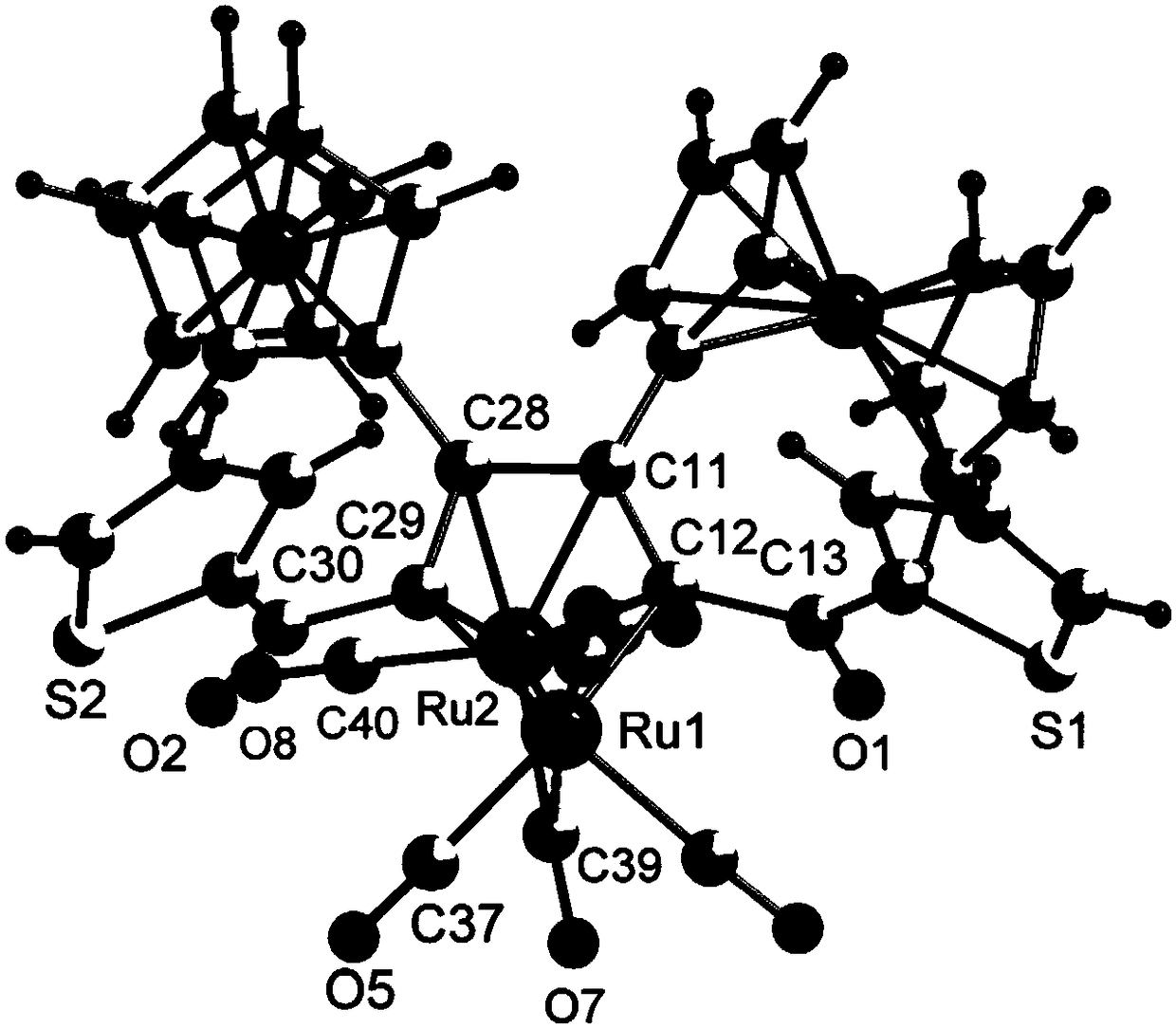

[0029] Add 0.2826g (0.9mmol) 1-phenyl-3-ferrocenyl prop-2-yn-1-one and 0.1918g (0.3mmol) triruthenium dodecacarbonyl to a 50mL reaction flask, add 15mL dry Toluene, stirred and reacted at 90° C. for 2 hours, and separated by column chromatography (with the volume ratio of dichloromethane and petroleum ether being 5:1 as the eluent), the ferrocene ruthenium metal cluster compound with the following structural formula was obtained:

[0030]

[0031] Its yield is 27%, and the structural characterization data is: FT-IR (KBr, cm -1 ):3090w, 3058w, 2926w, 2078vs, 2050vs, 2011vs, 1982vs; 1 H NMR (400MHz, CDCl 3 )δ7.93-7.94(d,2H),7.76-7.78(t,2H),7.30-7.58(m,6H),3.67-4.05(m,18H); 13 C NMR (101MHz, CDCl 3 )δ=197.26,196.56,196.06,193.98,193.72,193.33,164.65,136.31,135.58,134.81,133.73,132.43,129.58,129.33,128.89,128.48,128.03,97.25,81.90,75.61,71.21,70.72,70.24,69.72 , 68.63, 68.56, 68.52, 68.42, 68.18, 67.49; ESI-MS: C 44 h 28 Fe 2 o 8 Ru 2 ([M+Na] + ) The theoretical value...

Embodiment 2

[0033]Add 0.2826g (0.9mmol) 1-phenyl-3-ferrocenyl prop-2-yn-1-one and 0.1918g (0.3mmol) triruthenium dodecacarbonyl to a 50mL reaction flask, add 15mL dry Toluene, stirred and reacted at 90° C. for 2 hours, and separated by column chromatography (with the volume ratio of dichloromethane and petroleum ether being 4:1 as the eluent), the ferrocene ruthenium metal cluster compound with the following structural formula was obtained:

[0034]

[0035] Its yield is 25%, and the structural characterization data is: FT-IR (KBr, cm -1 ):3090w, 2926w, 2852w, 2096vs, 2060vs, 2035vs, 2014vs, 1854m; 1 H NMR (400MHz, CDCl 3 )δ7.93-8.19(m,2H),7.77-7.83(m,2H),7.32-7.62(m,6H),3.98-4.90(m,18H); 13 C NMR (101MHz, CDCl 3 )δ=203.50,198.49,197.25,195.72,195.05,189.09,184.19,164.07,137.18,136.76,136.55,133.72,133.29,133.17,132.94,132.85,132.42,129.63,129.58,129.33,128.91,128.62,128.55,128.17 ESI-MS: C 44 h 28 Fe 2 o 8 Ru 2 ([M+H] + ) The theoretical value is 1001.858, and the measured v...

Embodiment 3

[0037] Add 0.2826g (0.9mmol) 1-phenyl-3-ferrocenyl prop-2-yn-1-one and 0.1918g (0.3mmol) triruthenium dodecacarbonyl to a 50mL reaction flask, add 15mL dry Toluene, stirred and reacted at 90° C. for 2 hours, and separated by column chromatography (with the volume ratio of dichloromethane and petroleum ether being 3:1 as the eluent), the ferrocene ruthenium metal cluster compound with the following structural formula was obtained:

[0038]

[0039] Its yield is 29%, and the structural characterization data is: FT-IR (KBr, cm -1 ):3095w, 3056w, 2962w, 2926w, 2852w, 2085s, 2056vs, 2027vs, 20013vs, 1988vs, 1637m; 1 H NMR (400MHz, CDCl 3 )δ8.01-8.03(d,4H),7.46-7.56(m,6H),4.21-4.22(d,2H),4.14-4.15(d,2H),4.02-4.03(d,2H),3.96- 3.97(d,2H),3.02(s,10H); 13 C NMR (101MHz, CDCl 3 )δ=195.56, 195.05, 194.83, 193.14, 135.61, 132.69, 130.14, 128.91, 128.04, 84.26, 74.28, 71.58, 70.40, 68.73, 68.55, 67.58; ESI-MS: C 44 h 28 Fe 2 o 8 Ru 2 ([M+Na] + ) The theoretical value is 1001.85...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com