Method for preparing rear earth Y type molecular sieve

A molecular sieve and rare earth technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as uneven distribution of rare earth ions, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

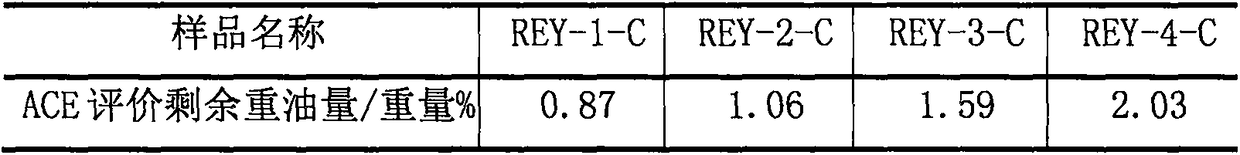

Embodiment 1

[0053] Weigh 177 grams of NaY molecular sieve (about 150 grams on a dry basis), add 750 grams of deionized water at 70°C, add 9 grams of lanthanum chloride while stirring, stir and exchange at 70°C for 60 minutes, and then add oxalic acid with a concentration of 15% solution, continue to stir for 20 minutes, then wash and filter with 225 grams of deionized water at 70°C, and discard the waste filtrate to obtain a reuse filter cake; add 525 grams of deionized water at 50°C to the reuse filter cake, while Add 52.5 grams of lanthanum chloride while stirring, stir for 60 minutes at 50°C, then wash and filter with 225 grams of 70°C deionized water to obtain product filter cake A and reuse filtrate C; 177 grams of NaY molecular sieve ( about 150 grams on a dry basis), was added to 750 g of recycled filtrate C, stirred at 70°C for 60 minutes, then added with a concentration of 15% oxalic acid solution, continued to stir for 20 minutes, and then deionized with 225 grams of 70°C Wash w...

Embodiment 2

[0055] Weigh 177 grams of NaY molecular sieve (about 150 grams on a dry basis), add 750 grams of deionized water at 60°C, add 9 grams of lanthanum chloride while stirring, stir and exchange at 60°C for 60 minutes, and then add oxalic acid with a concentration of 15% solution, continue stirring for 20 minutes, then wash and filter with 225 grams of deionized water at 60°C, and discard the waste filtrate to obtain a reuse filter cake; add 525 grams of deionized water at 50°C to the reuse filter cake, and Add 45.0 grams of lanthanum chloride while stirring, stir for 60 minutes at 60° C., then wash and filter with 225 grams of deionized water at 60° C. to obtain product filter cake A and reuse filtrate C; 177 grams of NaY molecular sieve ( about 150 grams on a dry basis), was added to 750 g of recycled filtrate C, stirred at 60°C for 60 minutes, then added with a concentration of 15% oxalic acid solution, continued to stir for 20 minutes, and then deionized with 225 grams of 60°C ...

Embodiment 3

[0057]Weigh 177 grams of NaY molecular sieve (about 150 grams on a dry basis), add 750 grams of deionized water at 50°C, add 9 grams of lanthanum chloride while stirring, stir and exchange at 50°C for 60 minutes, and then add oxalic acid solution with a concentration of 15% , continue to stir for 20 minutes, then wash and filter with 225 grams of deionized water at 50°C, and discard the waste filtrate to obtain a reuse filter cake; add 525 grams of deionized water at 50°C to the reuse filter cake, while stirring While adding lanthanum chloride 37.5 grams, stirred at 50 DEG C for 60 minutes, then washed and filtered with 225 grams of deionized water at 50 DEG C to obtain product filter cake A and reuse filtrate C; 177 grams of NaY molecular sieve (dry base about 150 grams), added to 750 g of reuse filtrate C, stirred for 60 minutes at 50°C, then added a 15% oxalic acid solution, continued to stir for 20 minutes, and then used 225 grams of 50°C deionized water Washing, filtering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com