Preparation method of nano-metal oxide and porous activated carbon composite

A porous activated carbon, nano-metal technology, applied in the directions of alkali metal oxides/hydroxides, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of loss, limited amount of inorganic components, clogging of activated carbon, etc. High utilization and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 4 grams of FeSO4·7H2O, stir and dissolve in 100ml of water; add 40 grams of potato starch into the solution, and stir until completely dissolved. Subsequently, the mixed solution was placed in a 200 ml sealed reaction kettle with a polytetrafluoroethylene liner, and reacted in an oven at 200° C. for 5 hours. After taking it out, the reactor was cooled naturally, and the mixed solution was filtered, and the solid was dried in an oven at 100° C. for 12 hours.

[0035] The above-mentioned solid obtained after drying was placed in a tube furnace, and CO2 gas was passed through, and the gas flow rate was 48L / h; the tube furnace was heated to 800°C at a speed of 10°C / min, and kept for 2 hours. After the reaction furnace is naturally cooled, the composite material of nano ferric oxide grains and activated carbon is obtained.

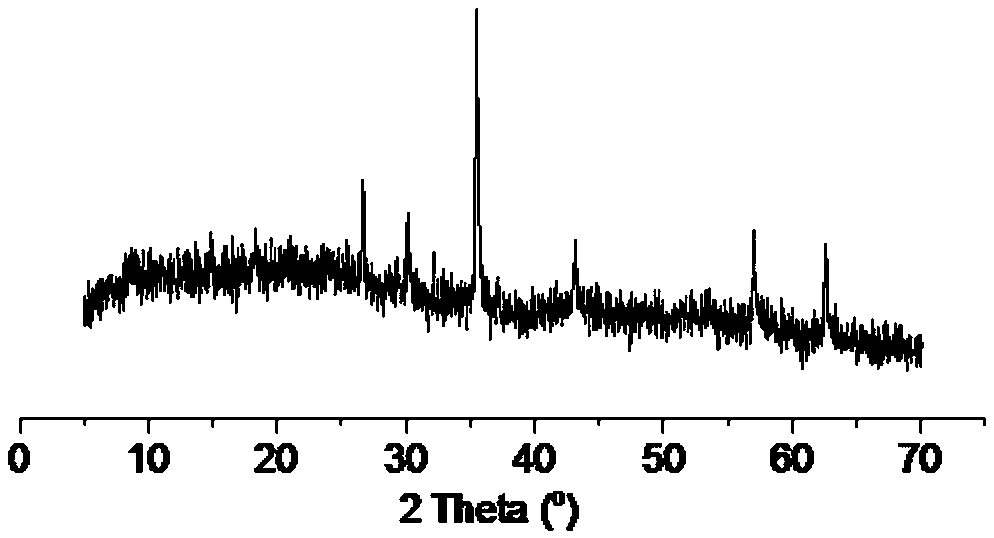

[0036] The XRD spectrogram shows the amorphous peak package of activated carbon, and the characteristic peak of Fe3O4 crystal (see the appendix f...

Embodiment 2

[0039] Take 0.354 g of ZrOCl2·8H2O, stir and dissolve in 12.5 ml of water, add 5 g of potato starch into the solution, and stir until completely dissolved. The mixed solution was placed in 50 ml sealed reaction kettle with polytetrafluoroethylene liner, and reacted in an oven at 200° C. for 24 hours. After taking it out, the reactor was cooled naturally, and the mixed solution was filtered, and the solid was dried in an oven at 100° C. for 12 hours.

[0040]The above-mentioned solid obtained after drying was placed in a tube furnace, and CO2 gas was passed through, and the gas flow rate was 48L / h; the tube furnace was heated to 800°C at a speed of 10°C / min, and kept for 2 hours. The composite material of zirconia and activated carbon can be obtained after the reaction furnace is naturally cooled.

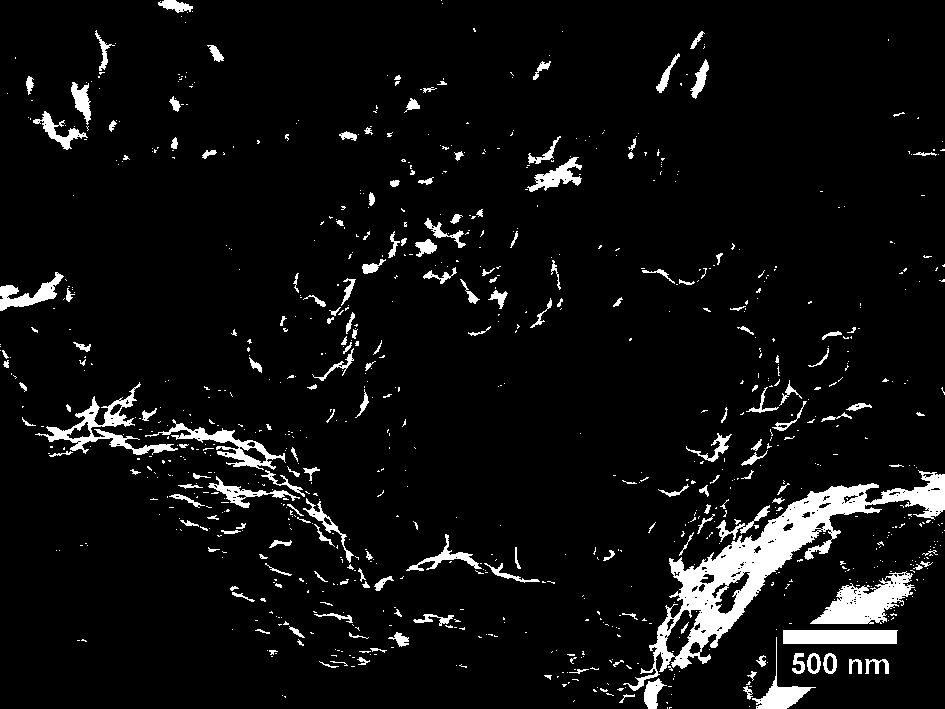

[0041] The XRD spectrogram shows the amorphous peak package of activated carbon, as well as the characteristic peaks of ZrO2 crystals (see the appended Figure 6 ); scanning elect...

Embodiment 3

[0043] Take 0.726 g of MgCl2, stir and dissolve in 12.5 ml of water, add 5 g of potato starch into the solution, and stir until completely dissolved. The mixed solution was placed in 50 ml sealed reaction kettle with polytetrafluoroethylene liner, and reacted in an oven at 200° C. for 24 hours. After taking it out, the reactor was cooled naturally, and the mixed solution was filtered, and the solid was dried in an oven at 100° C. for 12 hours.

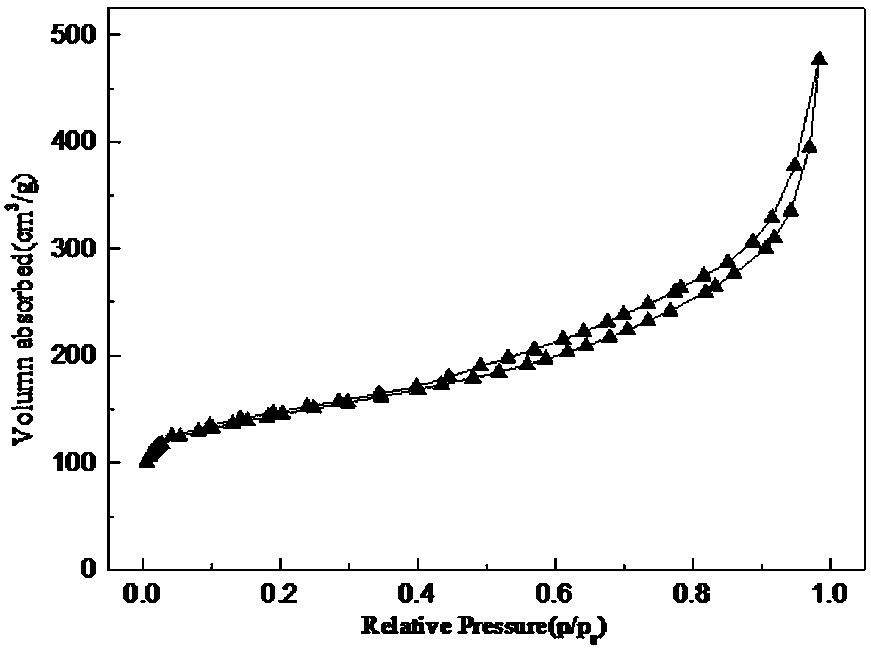

[0044] The above-mentioned solid obtained after drying was placed in a tube furnace, and CO2 gas was passed through, and the gas flow rate was 48L / h; the tube furnace was heated to 800°C at a speed of 10°C / min, and kept for 2 hours. The composite material of magnesium oxide and activated carbon can be obtained after the reaction furnace is naturally cooled. The XRD spectrogram shows the amorphous peak package of activated carbon, as well as the characteristic peaks of MgO crystals (see the appended Figure 10 ); the BET specific surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com