Fabric defect detection method based on distance matching function and perceptual hash algorithm

A perceptual hash algorithm, distance matching technology, applied in computing, image data processing, instruments, etc., to achieve the effect of fast computing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

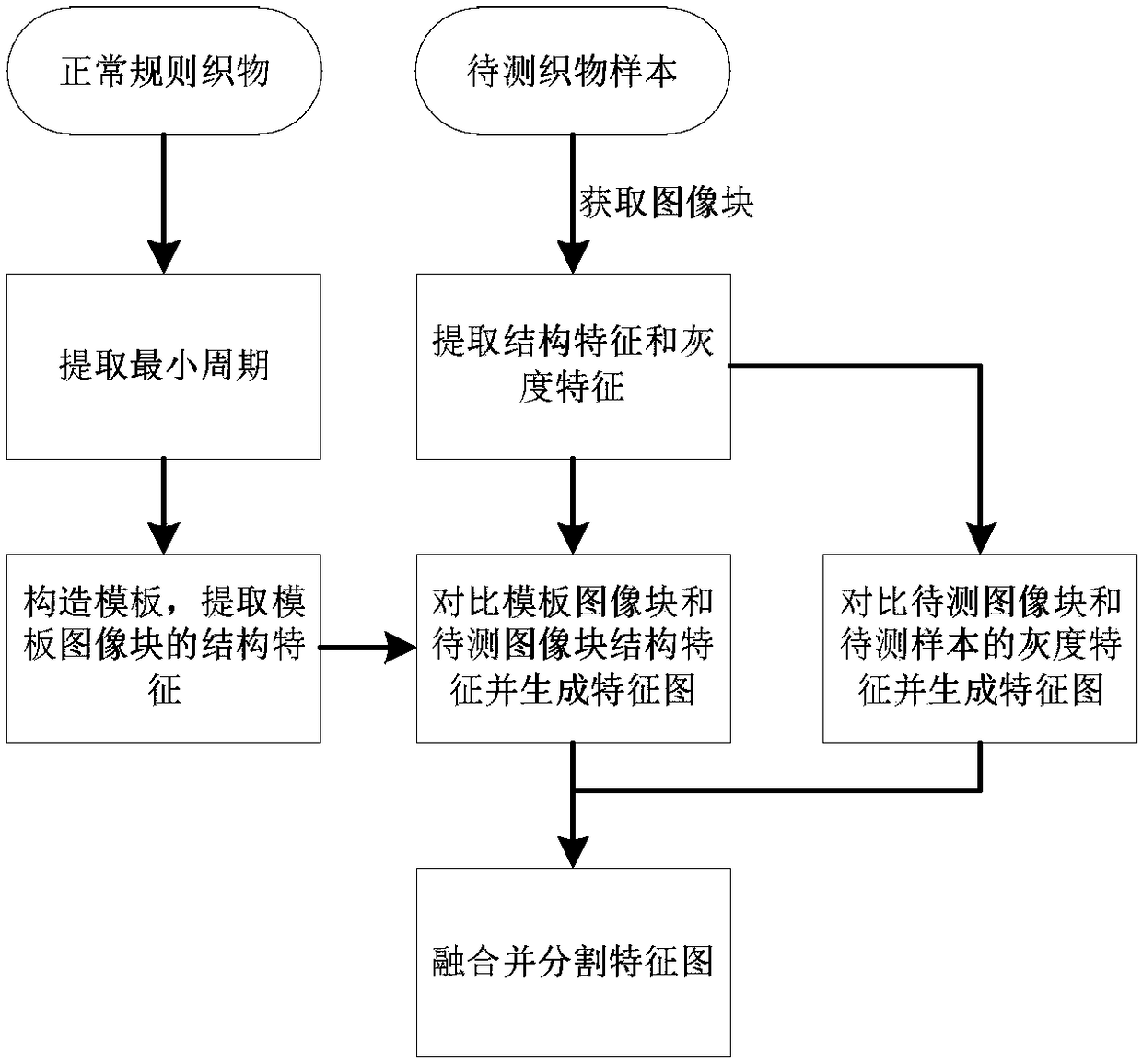

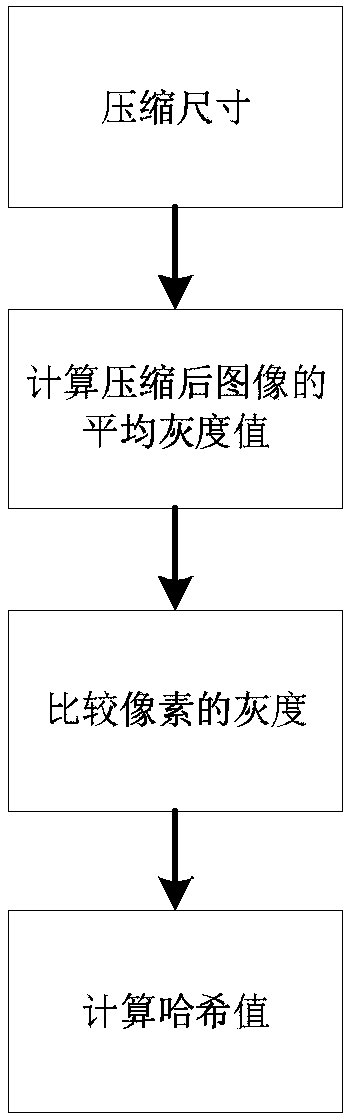

Method used

Image

Examples

Embodiment

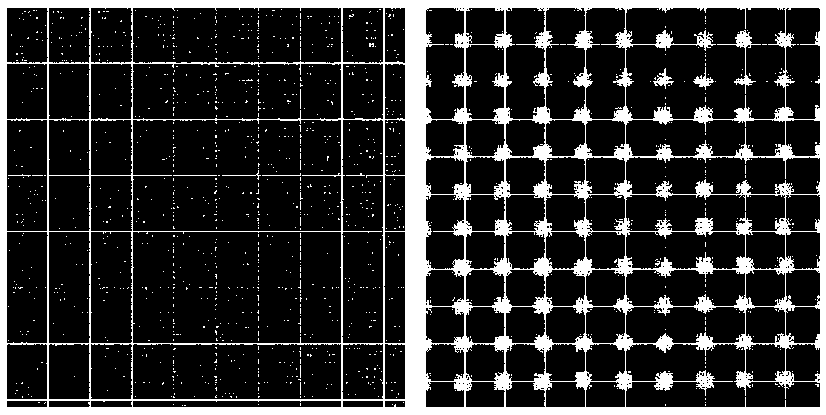

[0050] Embodiment: Select several types of common fabric defect images (holes, warp breaks, oil stains, scratches, etc.) from the fabric image library, and the size of the pictures is 256pixel×256pixel. Select some images, such as Figure 5 (first row). Using the algorithm of the present invention to obtain the structure feature map and the grayscale feature map, such as Figure 5 (second row, third row). Finally, the fusion feature map and defect segmentation image are obtained, where θ 1 =6, θ 2 =8, the result is as Figure 5 (line 4, line 5), the final result (line 6) is obtained, and it can be seen that the defect has been detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com