Efficient slice loading and unloading system and pathological slice scanner

A loading and unloading system and loading system technology, applied in the field of pathological slice scanners, can solve the problems of difficult time compression, unbalanced scanning platform, slice damage, etc., and achieve the effect of halving the slice loading and unloading time and improving the overall efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to illustrate the technical solutions of the present invention more clearly, specific implementations of the present invention will be described below in conjunction with the accompanying drawings.

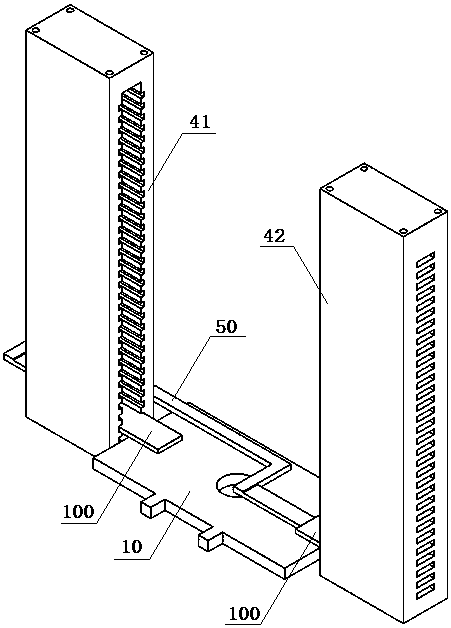

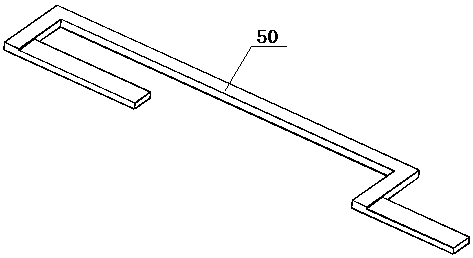

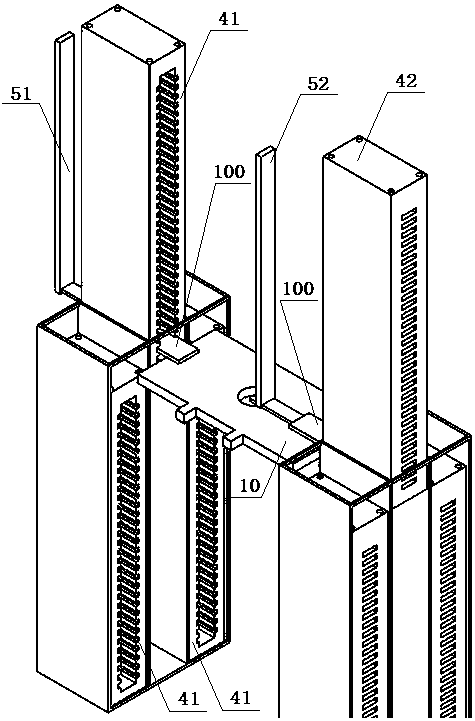

[0021] Such as figure 1 As shown, the slice loading and unloading system of the present invention includes: a loading slice box 41, an unloading slice box 42, a loading and unloading manipulator 50, and a slice box position adjustment device; the loading and unloading manipulator 50 is used to move the scanned slices on the stage into The unloading slice box 42 on one side of the stage 10; at the same time, the loading and unloading manipulator 50 moves the slices in the slice box 41 from the other side of the stage 10 into the stage; the position adjustment device for the slice box is used for The loading and unloading slice boxes are lifted and lowered, so that different slice grooves of the unloaded slice boxes are aligned with the unloading stations of the stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com