Operation control method of three-section walking beam

A technology of operation control and walking beam, which is applied in the field of steel rolling reheating furnace, and can solve problems such as failure to meet the requirements of linkage or different synchronous distances between two sections of beams, damage to walking equipment, and billet jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

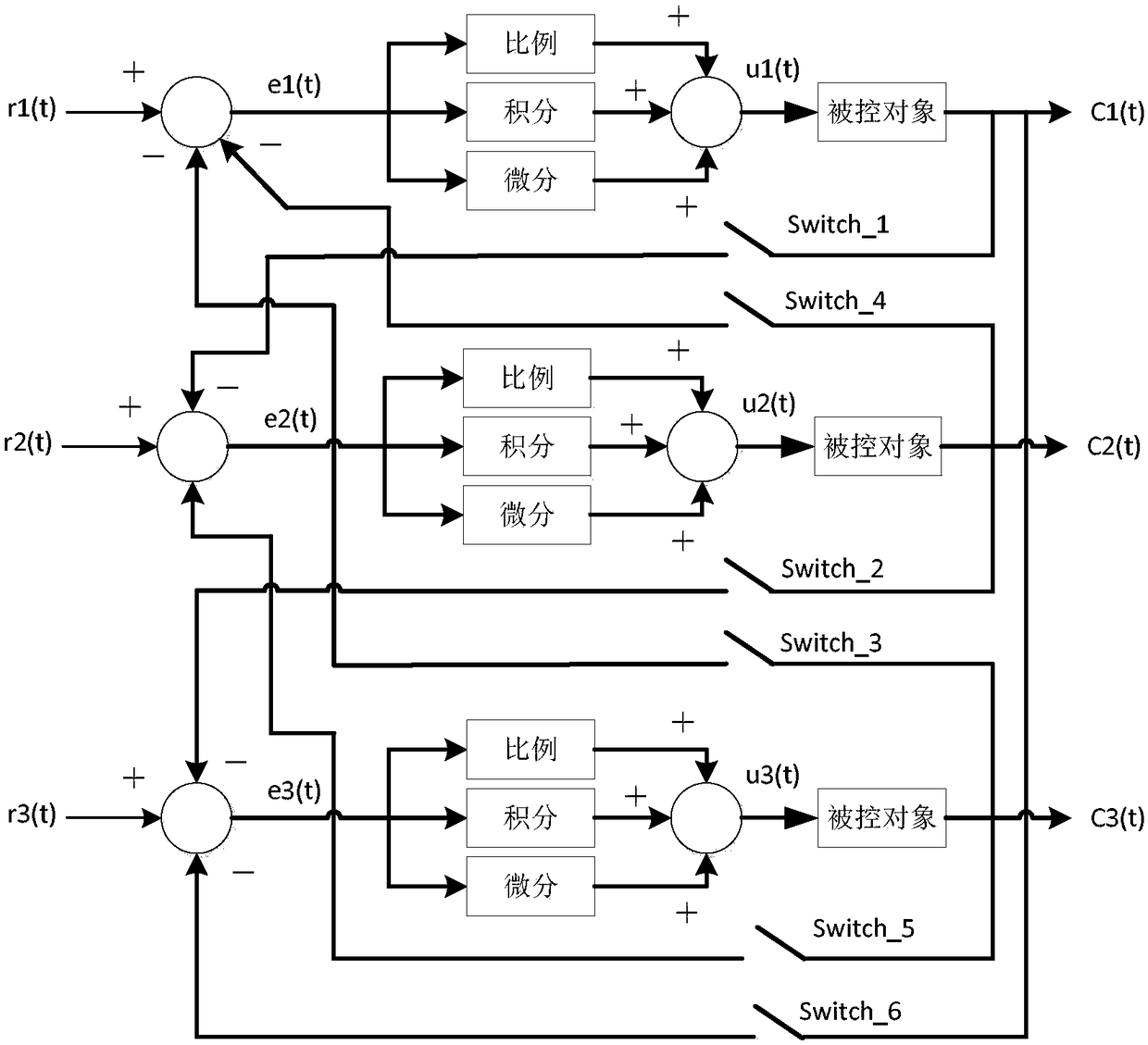

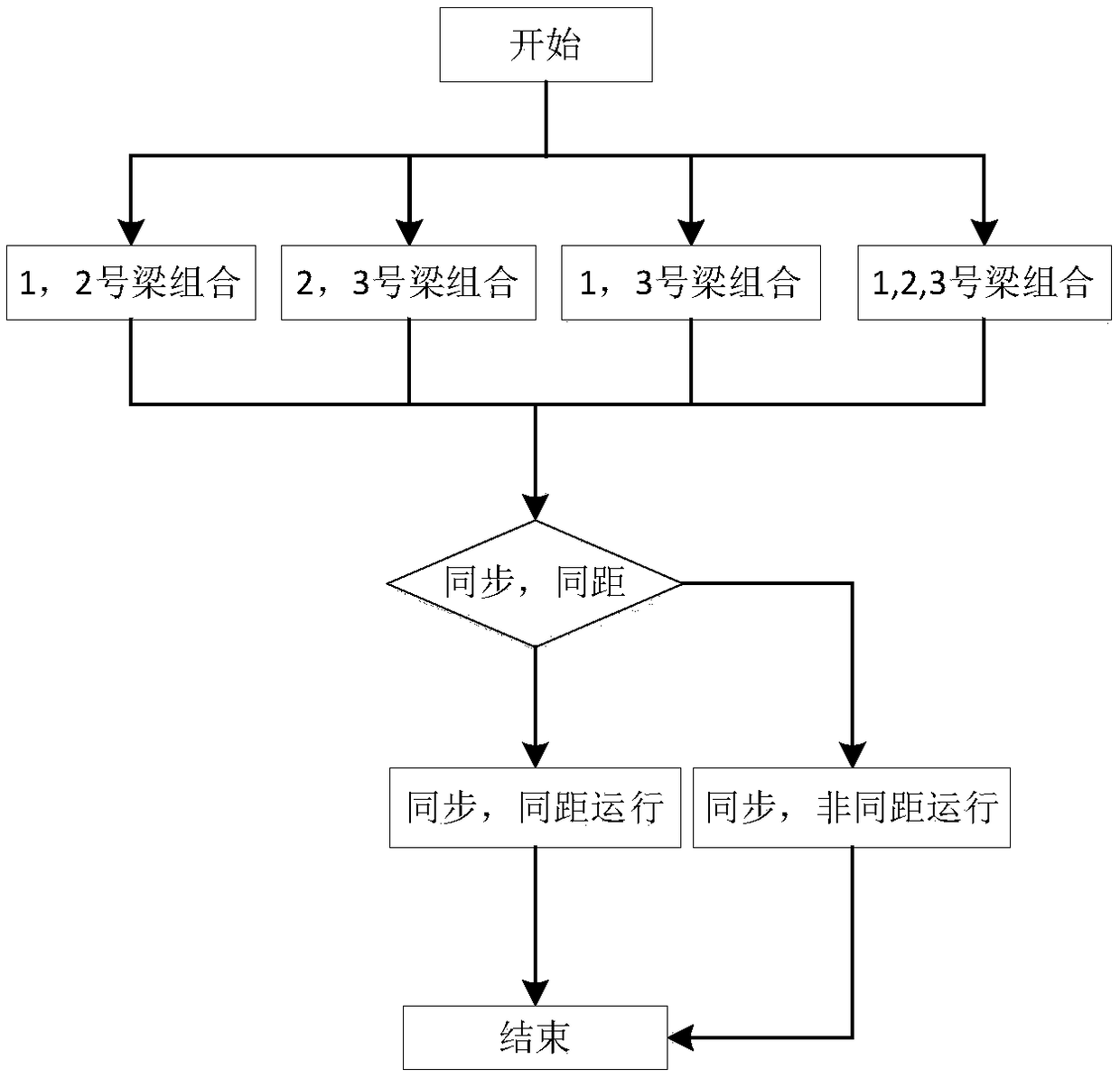

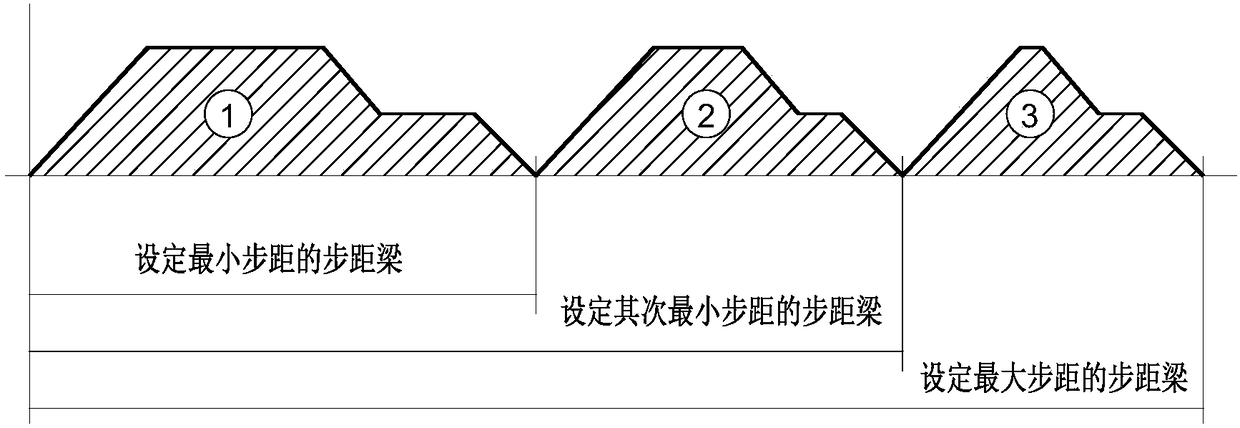

[0036] An embodiment of the present invention discloses a method for controlling the operation of a three-stage walking beam. The operation of the three-stage walking beam adopts feedback control combining PID three-cross and double-cross. Specifically, such as figure 1 As shown, the feedback control of the PID three-cross and double-cross combination includes: when the three-section walking beam is running synchronously, the operation result of each section of the walking beam is fed back to the control loop of the other two walking beams; or,

[0037] When any two sections of the three-section w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com