Fibre optic fusion splicer

一种光纤熔接机、光纤的技术,应用在光纤熔接领域,能够解决电极棒或V-槽破损等问题,达到消除排列误差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Other objects, features, and advantages of the present invention will be clarified through the detailed description of the embodiments with reference to the accompanying drawings.

[0034] Below, the structure and function of the embodiments of the present invention will be described with reference to the accompanying drawings. The structure and function of the present invention illustrated and illustrated with the help of figures can be described as at least one embodiment. Its core composition and function are not limited by the above description.

[0035] Hereinafter, preferred embodiments of the optical fiber fusion splicer according to the present invention will be described in detail with reference to the accompanying drawings.

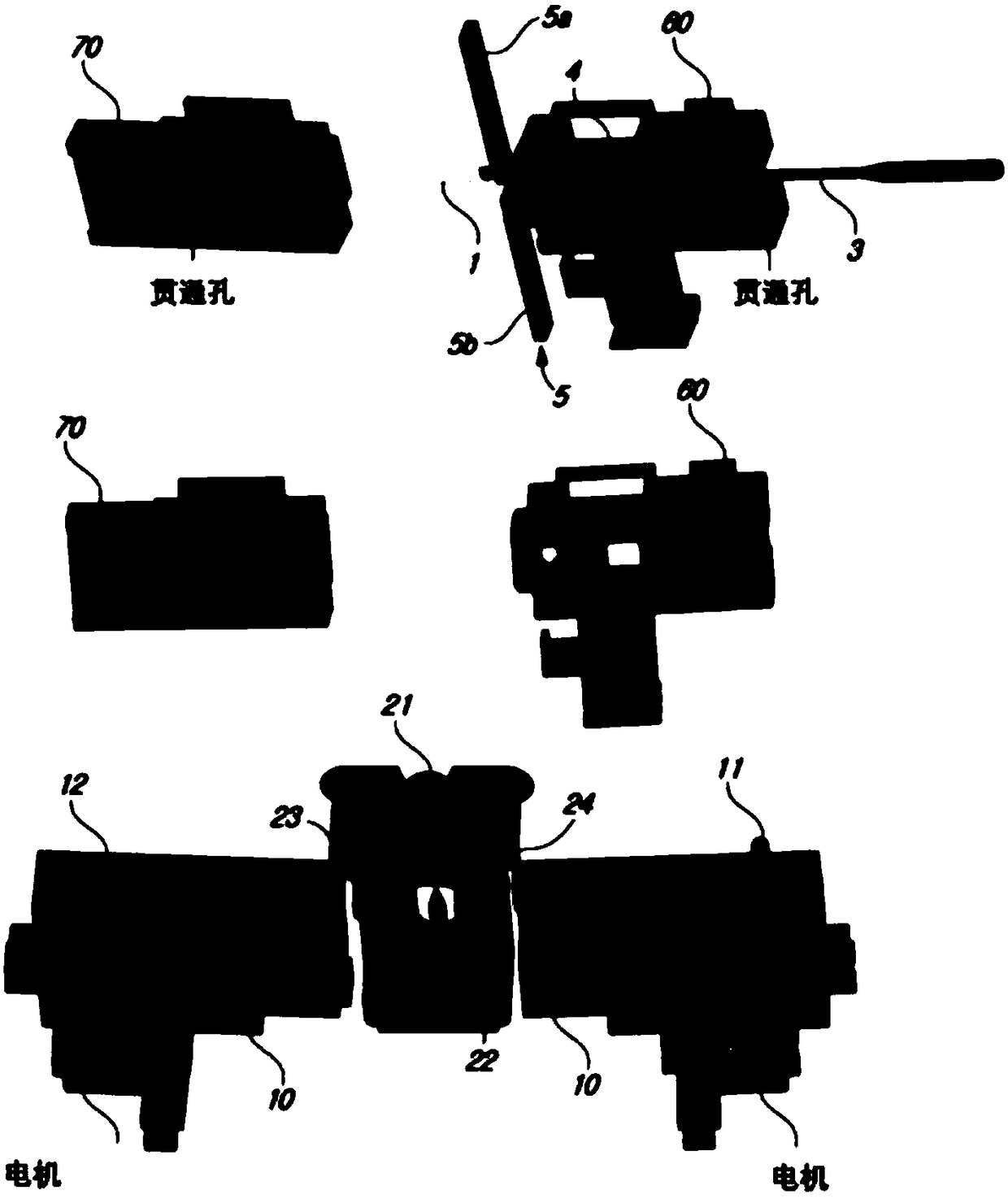

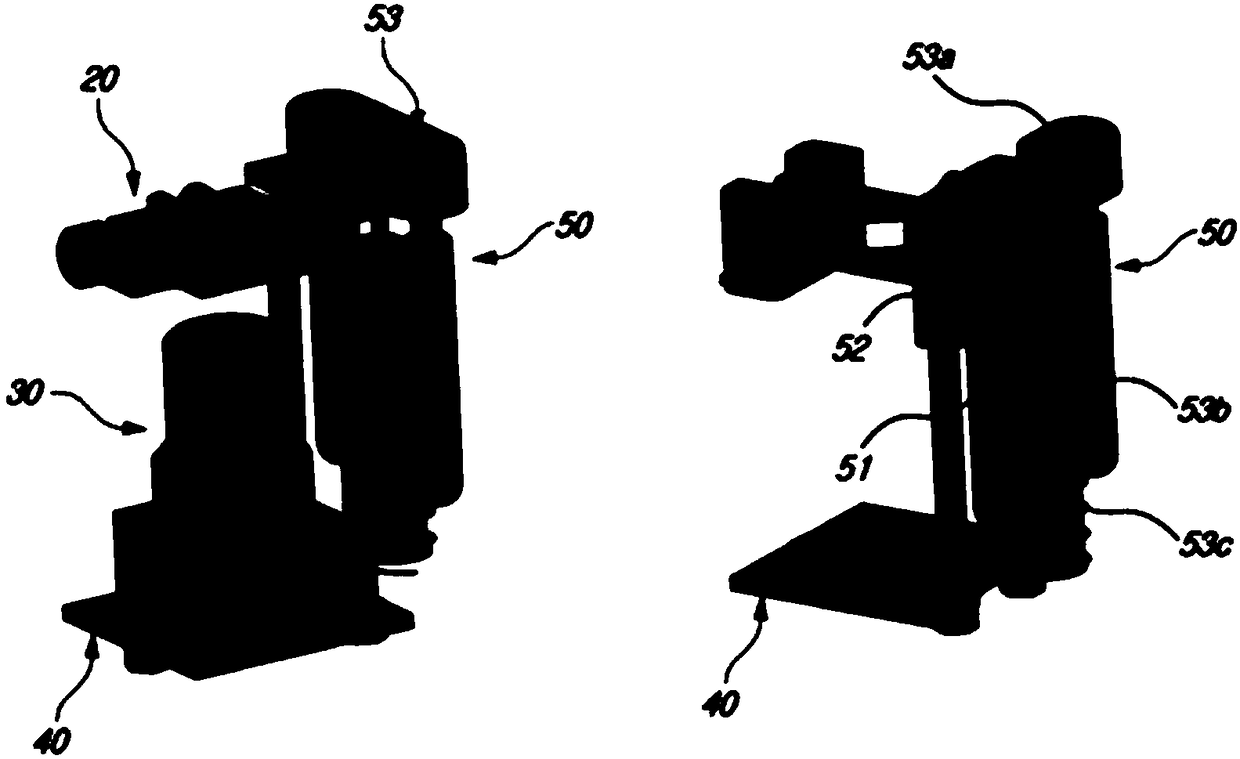

[0036] figure 1 In order to show the perspective view and block diagram of the overall composition of the optical fiber fusion splicer according to the present invention, figure 2 It is a perspective view showing the structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com