Crossing hole mesh slotting and permeability increasing method

A technology of drilling through layers and slitting, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc. problems, to achieve the effect of increasing the effective scope of influence, widely promoting the application value, and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

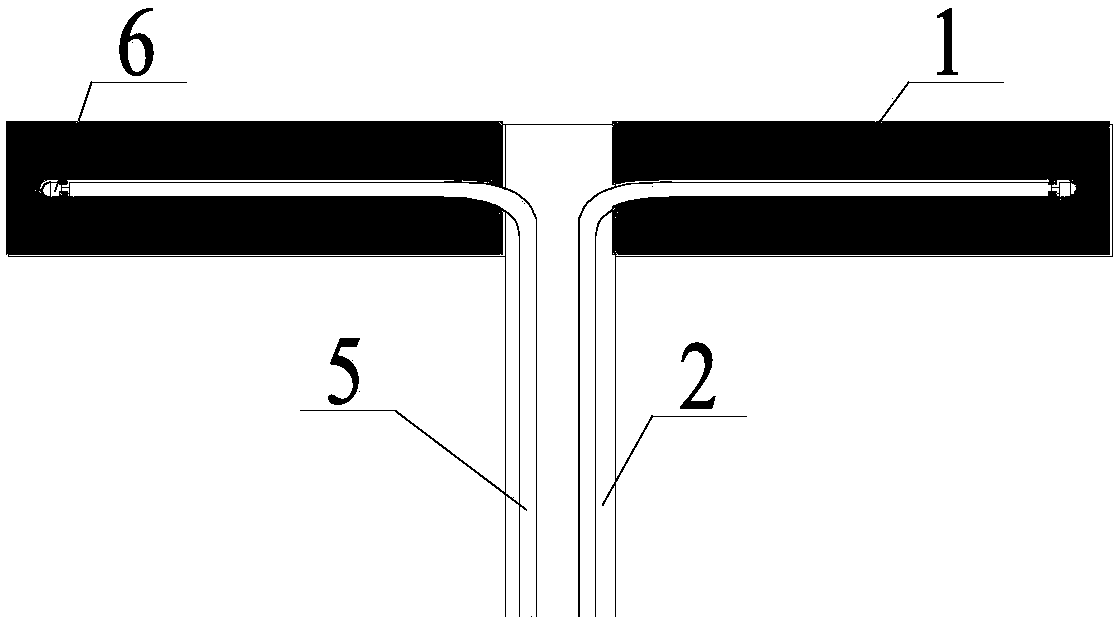

[0026] 1. First, use a drilling rig to construct a layer-penetrating drilling 2 to the design depth of the coal body 1 on the working face to be excavated or to be mined, such as figure 1 shown;

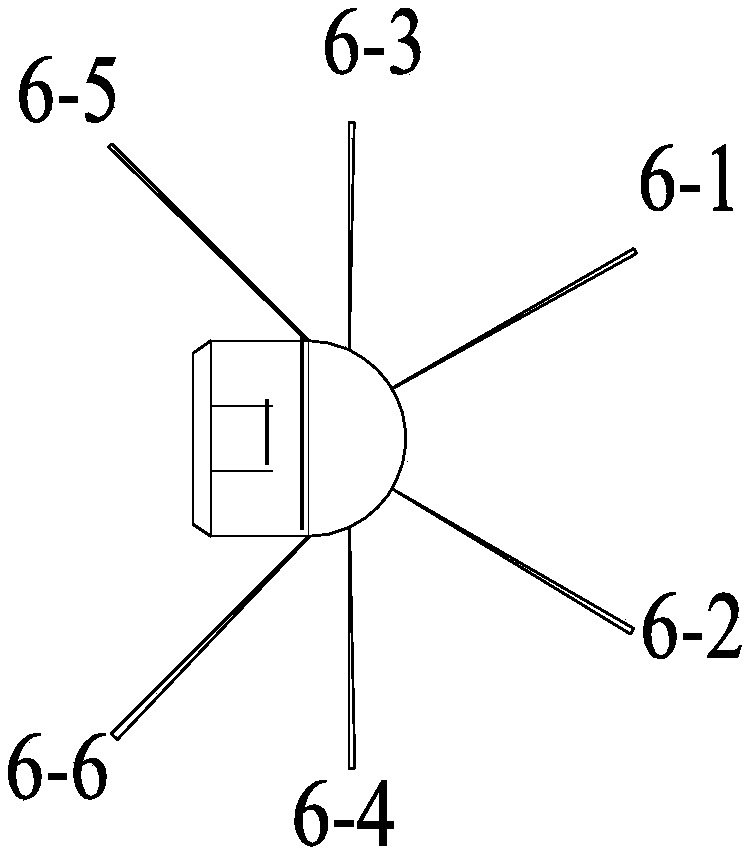

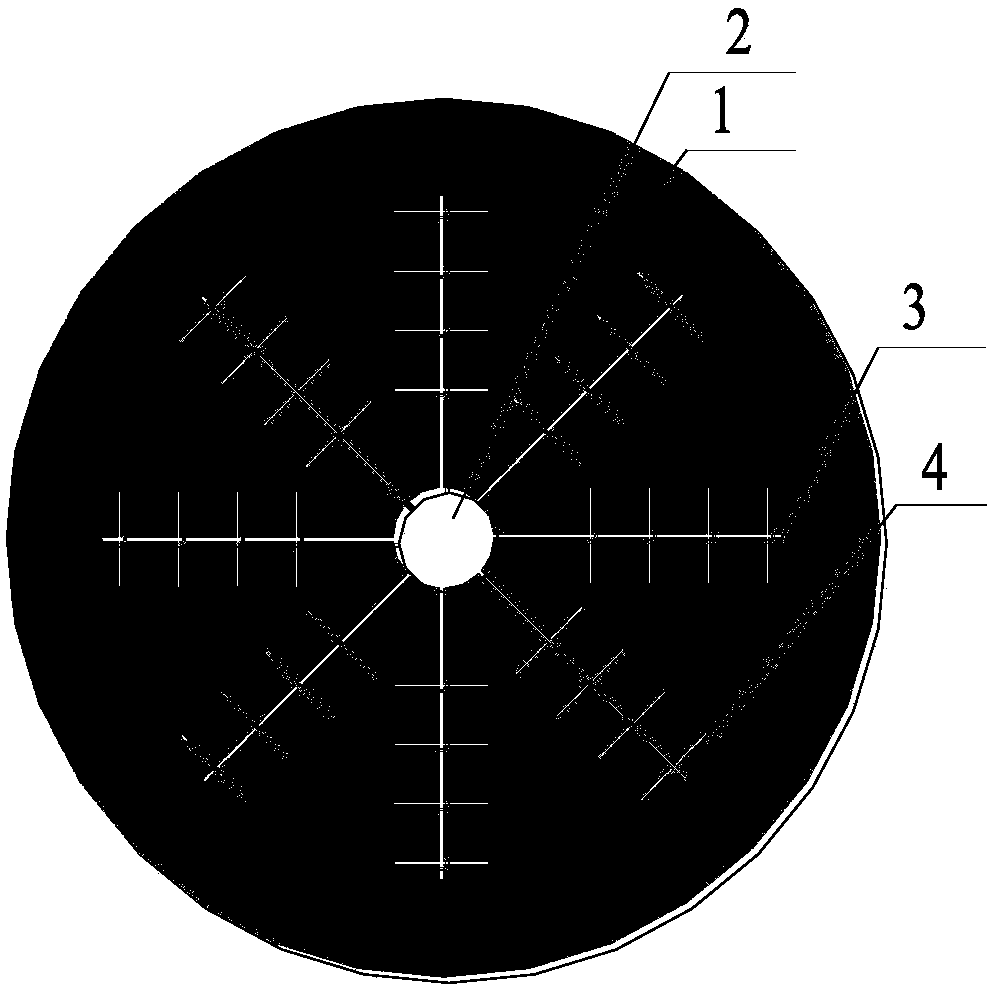

[0027] 2. After the construction of the through-bed drilling 2 is completed, the drill pipe is withdrawn, and the medium-pressure water with a pressure of 10-30 MPa is introduced to advance to the middle of the coal seam through the self-advancing high-pressure hose 5, and enters the coal seam by bending 90° through the guide device. A coal seam drilling 3 with a vertical drilling length of 5 to 15 m around the seam drilling 2;

[0028] 3. After the completion of the drilling 3 along the coal seam, during the retreat process of the self-propelled high-pressure hose 5, the high-pressure water with a pressure of 30-100 MPa is input every 1-3m to cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com