Coal mixing method and apparatus suitable for coal gasification apparatus

A coal gasification and mixing technology, which is used in the feeding tools of gasification units, the manufacture of combustible gas, and the petroleum industry, etc., can solve the problems of unfavorable economic operation of the start-up and parking companies, and the inability to achieve continuous long-term stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. The technical solutions of the present invention will be described in detail below in conjunction with the examples, but the scope of protection is not limited thereto.

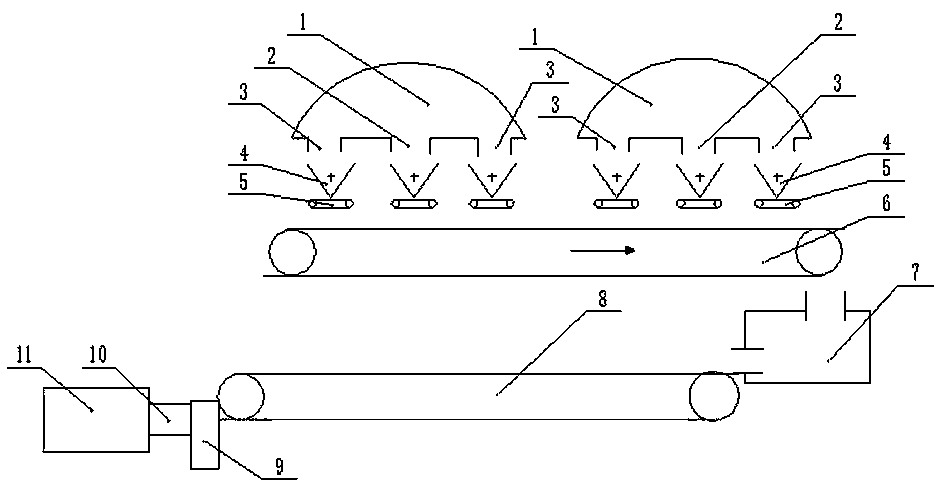

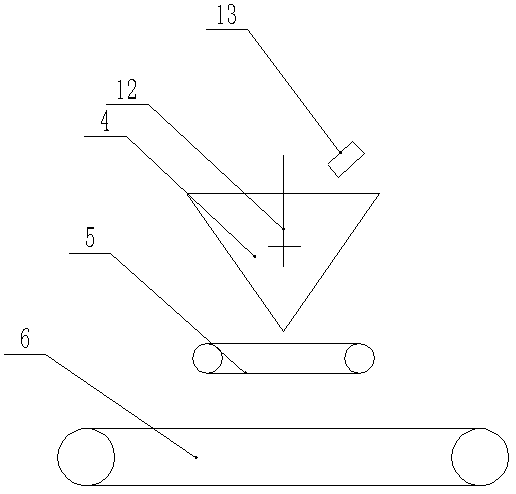

[0015] The present invention has a coal mixing device suitable for coal gasification treatment, including two semi-enclosed circular bunkers 1, and a set of car coal storage system and a train coal storage system are built for the semi-closed round bunkers 1. The system provides a coal source for the semi-enclosed circular bunker 1. The bottom of each semi-enclosed circular silo 1 is provided with a central discharge port 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com