Unconsolidated sandstone reservoir protection drilling fluid and preparation method thereof

A reservoir protection and drilling fluid technology, applied in the field of loose sandstone reservoir protection drilling fluid and its preparation, can solve problems such as increasing difficulty, and achieve the effects of reducing drilling tool corrosion, avoiding the formation of cuttings beds, and strong inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

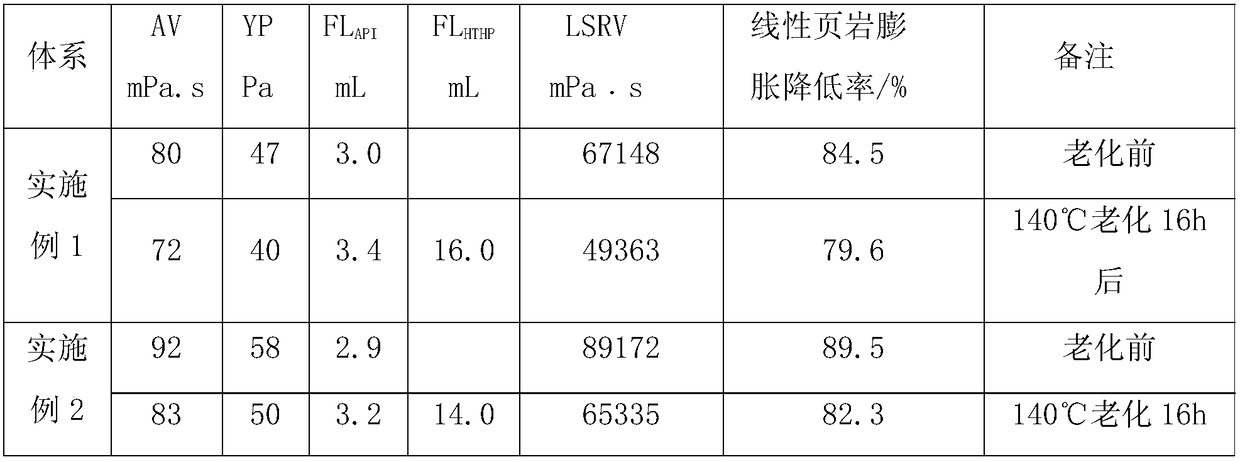

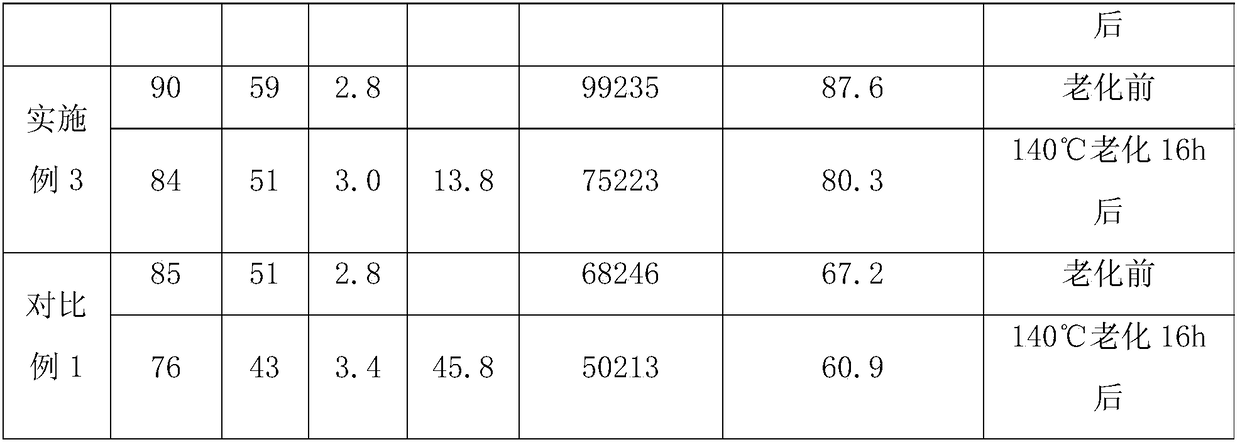

Embodiment 1

[0017] A kind of unconsolidated sandstone reservoir protection drilling fluid provided by the invention comprises 1% modified cassava flour, 1% xanthan gum, 1% hydroxyethyl cellulose, 1% sodium hydroxide, 0.5% sodium sulfite, 1% Polyethylene wax, 5% fine calcium, 1% potassium amino trimethylene phosphonate.

[0018] The preparation method of described loose sandstone reservoir protection drilling fluid is as follows:

[0019] (1) Add modified cassava flour, xanthan gum, and hydroxyethyl cellulose to water in turn, and stir for 40 minutes;

[0020] (2) Add sodium hydroxide and sodium sulfite, and stir for 10 minutes;

[0021] (3) Add polyethylene wax and fine-grained calcium, and stir for 10 minutes;

[0022] (4) Potassium aminotrimethylene phosphonate was added and stirred for 40 minutes to prepare the drilling fluid for protecting the loose sandstone reservoir.

Embodiment 2

[0024] A kind of unconsolidated sandstone reservoir protection drilling fluid provided by the invention comprises 2% acetylated distarch phosphate, 1% xanthan gum, 0.5% hydroxyethyl cellulose, 2% sodium hydroxide, 0.1% sodium sulfite, 1.5% polyethylene wax, 15% fine calcium, 2% potassium aminotrimethylene phosphonate.

[0025] The preparation method of described loose sandstone reservoir protection drilling fluid is as follows:

[0026] (1) Add the acetylated distarch phosphate, xanthan gum, and hydroxyethyl cellulose in water successively, and stir for 60 minutes;

[0027] (2) Add sodium hydroxide and sodium sulfite, and stir for 15 minutes;

[0028] (3) Add polyethylene wax and fine-grained calcium, and stir for 15 minutes;

[0029] (4) Potassium aminotrimethylene phosphonate was added and stirred for 45 minutes to prepare the drilling fluid for protection of loose sandstone reservoirs.

Embodiment 3

[0031] A kind of unconsolidated sandstone reservoir protection drilling fluid provided by the invention comprises 1% modified cassava flour, 1% acetylated distarch phosphate, 1.5% xanthan gum, 0.5% hydroxyethyl cellulose, 1.5% Sodium Hydroxide, 0.3% Sodium Sulfite, 1% Polyethylene Wax, 5% Fine Calcium, 1.5% Potassium Amino Trimethylene Phosphonate.

[0032] The preparation method of described loose sandstone reservoir protection drilling fluid is as follows:

[0033] (1) Add the modified cassava flour, acetylated distarch phosphate, xanthan gum, and hydroxyethyl cellulose in water successively, and stir for 30 minutes;

[0034] (2) Add sodium hydroxide and sodium sulfite, and stir for 20 minutes;

[0035] (3) Add polyethylene wax and fine-grained calcium, and stir for 20 minutes;

[0036] (4) Potassium aminotrimethylene phosphonate was added and stirred for 45 minutes to prepare the drilling fluid for protection of loose sandstone reservoirs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com