Epoxy resin thermal insulation composite material and preparation method thereof

A technology of epoxy resin and composite materials, applied in the field of composite materials, can solve the problem that the mechanical and thermal insulation properties cannot be taken into account at the same time, and achieve the effects of avoiding heat collection, increasing the force, and improving the impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

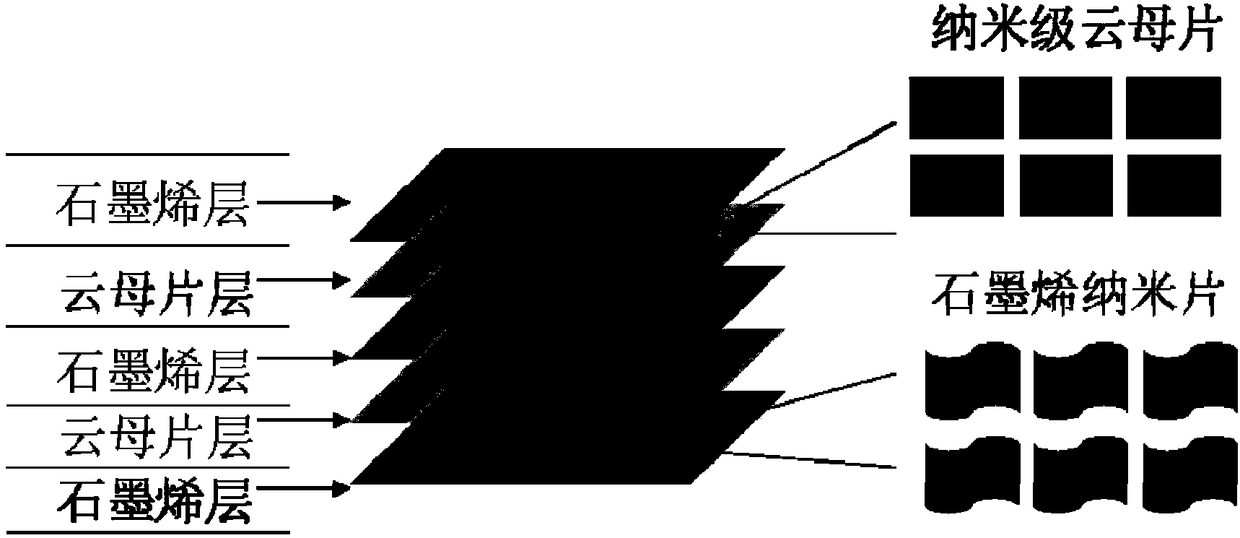

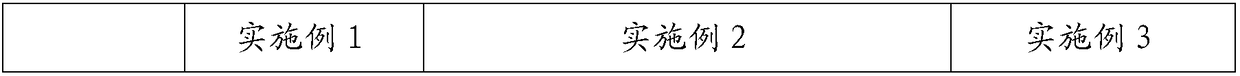

[0037] According to the naphthalene skeleton epoxy resin (NC-7000, X-N linear naphthol novolac epoxy resin, ESN-185) that table 1 selects, adopt the graphene nanoplate that diameter is 3 ± 0.5 micron, thickness is 5 ± 1 nanometer, diameter 4 ± 0.5 microns, a mica sheet with a thickness of 60 ± 5 nanometers, wherein the weight ratio of the graphene sheet to the mica sheet is 1:8, and finally obtain the epoxy resin heat-insulating composite material of Examples 1-3, wherein the heat-insulating layer Structural diagram such as figure 1 shown.

[0038] Table 1 Different Naphthalene Skeleton Epoxy Resins

[0039]

[0040]

Embodiment 4~5

[0042] Select naphthalene skeleton epoxy resin NC-7000, use mica flakes with a diameter of 4±0.5 microns and a thickness of 60±5 nanometers, in which the weight ratio of graphene flakes to mica flakes is 1:8, and graphites of different sizes are selected according to Table 2 ene nanosheets with a thickness of 5±1 nanometers to finally obtain the epoxy resin heat-insulating composite materials of Examples 4-5.

[0043] Table 2 Graphene nanosheets of different sizes

[0044]

Embodiment 6~7

[0046] Select naphthalene skeleton epoxy resin NC-7000, and use graphene nanosheets with a diameter of 3 ± 0.5 microns and a thickness of 5 ± 1 nm. The weight ratio of graphene sheets to mica sheets is 1:8. The size of the mica sheet and its thickness is 60 ± 5 nanometers, and finally the epoxy resin heat-insulating composite materials of Examples 6-7 are obtained.

[0047] Table 3 Mica sheets of different sizes

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com