Temporary stopping method for synthesis technology of methyl isobutyl ketone by acetone

A technology of methyl isobutyl ketone and acetone, which is applied in chemical instruments and methods, preparation of organic compounds, carbon-based compounds, etc., can solve problems such as low production efficiency, high product cost, broken catalysts, etc., and achieve energy saving consumption, high conversion rate, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

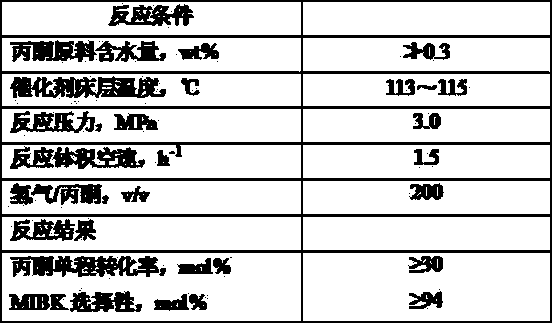

[0064] The experimental device, experimental reaction conditions and results are the same as those of Comparative Example 1.

[0065] The steps for shutting down the device are as follows:

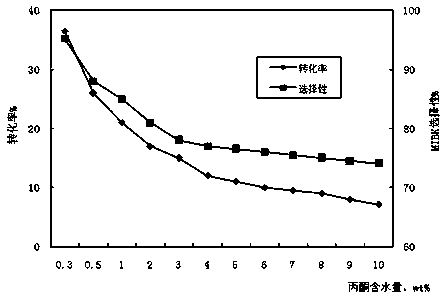

[0066] (1) After the device starts to shut down, start to introduce acetone with a water content of 0.5wt% into the reactor. According to previous experimental data, when the water content of acetone is 0.5 wt%, the conversion rate of the reaction drops from the normal 34.0% to 26.0%, so the heat of reaction released is also reduced by nearly a quarter. Therefore, the cooling rate at this time can reach 8.0-10.0°C / h, so the time required for the device to drop from the normal temperature to 110°C is 0.3-0.7 hours.

[0067] (2) After the catalyst bed temperature drops to 110°C, when the water content of the acetone feed is increased to 1.0wt%, it can be seen from the previous experimental data that the conversion rate of the reaction at this time drops to 21.0%, and the corresponding cooli...

Embodiment 2

[0073] The experimental device, experimental reaction conditions and results are the same as those of Comparative Example 2.

[0074] The steps for shutting down the device are as follows:

[0075] (1) After the device starts to shut down, start to introduce acetone with a water content of 0.5wt% into the reactor. According to previous experimental data, when the water content of acetone is 0.5 wt%, the conversion rate of the reaction drops from the normal 34.0% to 26.0%, so the heat of reaction released is also reduced by nearly a quarter. Therefore, the cooling rate at this time can reach 8.0-10.0°C / h, so the time required for the device to drop from the normal temperature to 105°C is 2.0-3.2 hours.

[0076] (2) After the temperature of the catalyst bed dropped to 105°C, the water content of the acetone-containing feed was increased to 1.0wt%. According to the previous experimental data, the conversion rate of the reaction at this time dropped to 21.0%, and the correspondin...

Embodiment 3

[0081] The experimental device, experimental reaction conditions and results are the same as those of Comparative Example 2.

[0082] The steps for shutting down the device are as follows:

[0083](1) After the device starts to shut down, start to introduce acetone with a water content of 0.5wt% into the reactor. According to previous experimental data, when the water content of acetone is 0.5 wt%, the conversion rate of the reaction drops from the normal 34.0% to 26.0%, so the heat of reaction released is also reduced by nearly a quarter. Therefore, the cooling rate at this time can reach 8.0-10.0°C / h, so the time required for the device to drop from the normal temperature to 110°C is 1.5-2.5 hours.

[0084] (2) After the temperature of the catalyst bed dropped to 110°C, the water content of the acetone-containing feed was increased to 1.0wt%. According to the previous experimental data, the conversion rate of the reaction at this time dropped to 21.0%, and the corresponding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com