Torsion damper for hybrid electric vehicle

A technology for torsional shock absorbers and hybrid vehicles, which is applied to the arrangement of multiple different prime movers of hybrid vehicles, general power plants, motor vehicles, etc. space problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

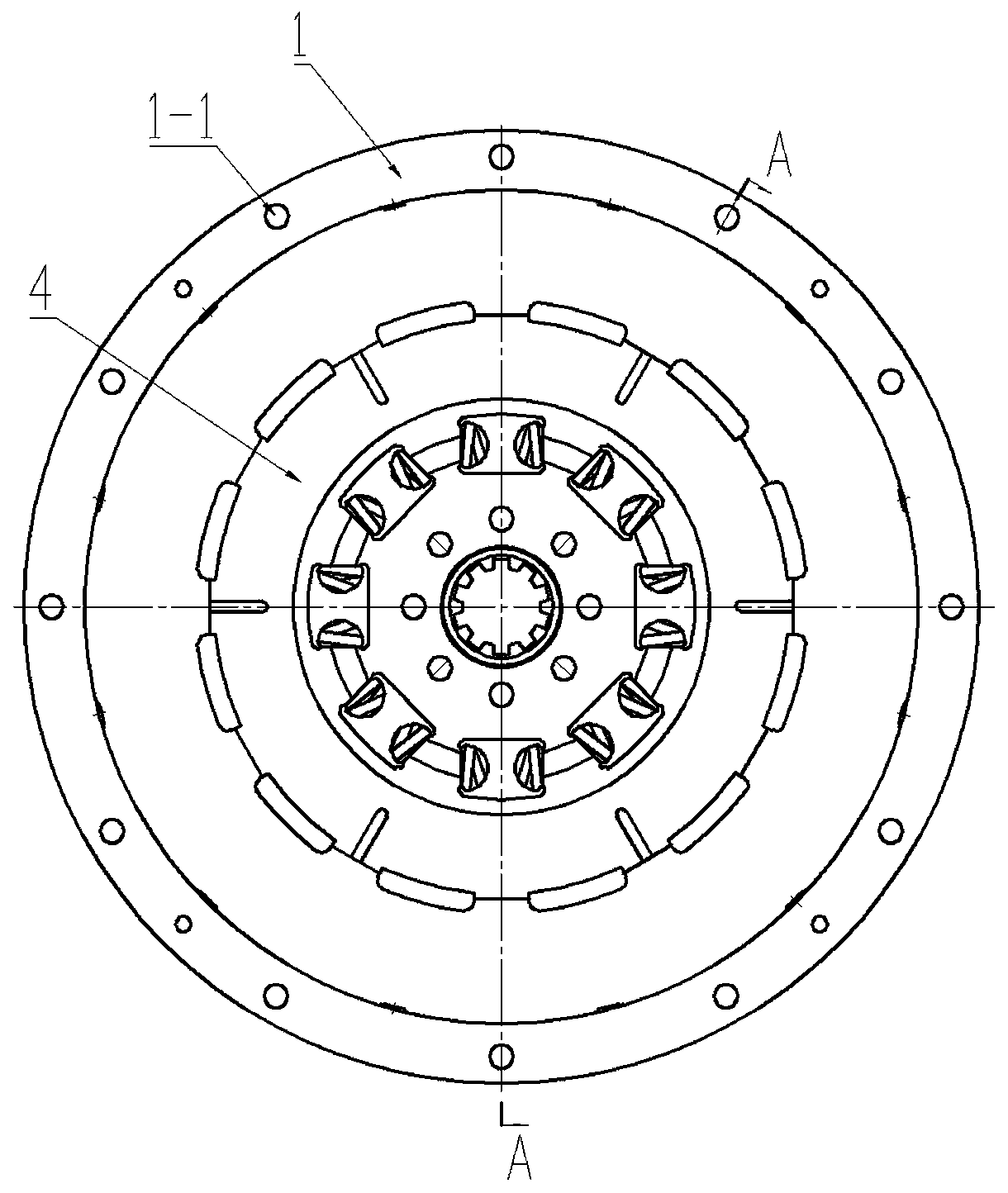

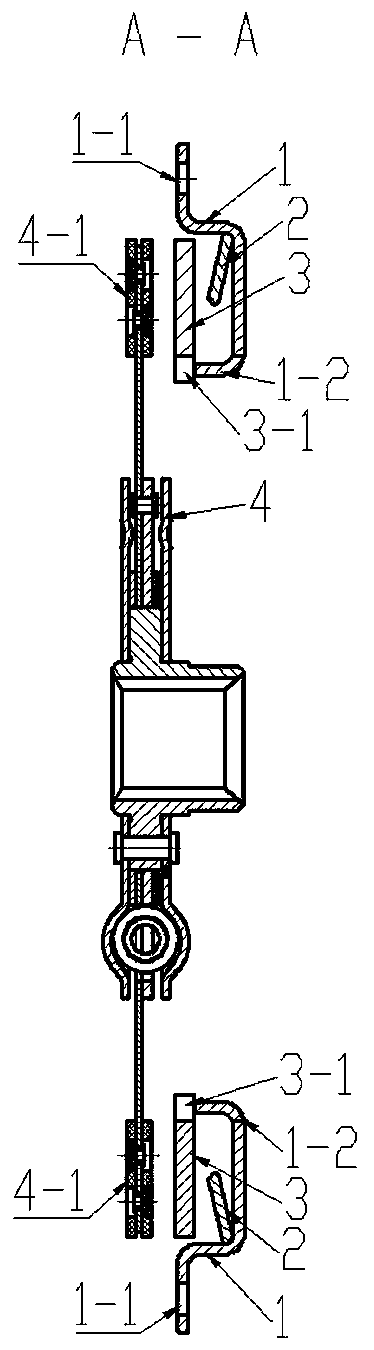

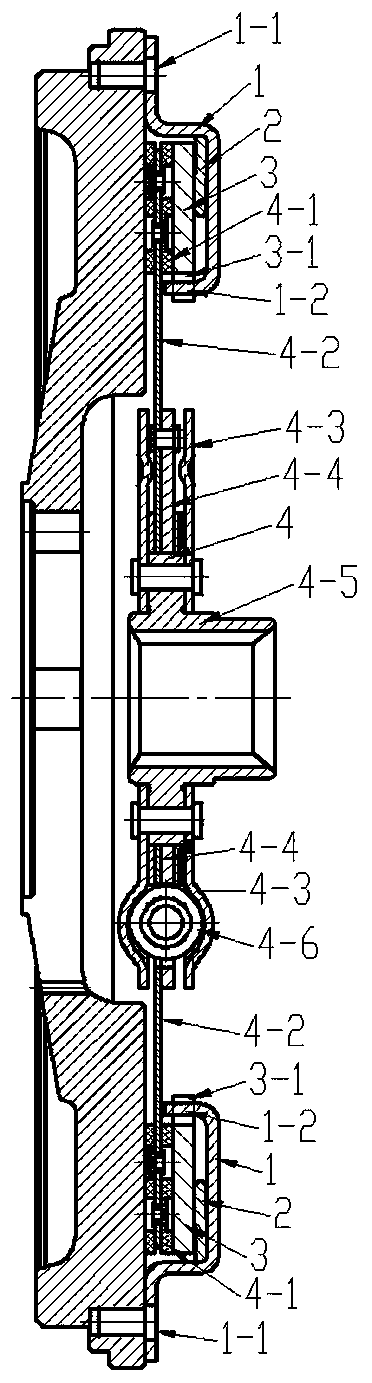

[0017] like Figure 1-3 As shown, a torsional shock absorber for a hybrid vehicle includes a driven disc 4, and also includes a friction disc 3 and a disc spring 2 stacked from bottom to top on the friction plate 4-1 of the driven disc 4 And cover 1, cover 1 covers the disc spring 2 and friction disc 3, the outer ring of cover 1 is provided with mounting holes 1-1, the inner ring is provided with claws 1-2, and the inner ring of friction disc 3 is provided with clamps Slot 3-1, the card slot 3-1 is adapted to the claw 1-2.

[0018] There are at least two jaws 1-2.

[0019] The size of the outer circle of the friction disc 3 is greater than or equal to the size of the outer circle of the friction plate 4-1.

[0020] The center position of the friction disc 3 is stacked with the center position of the driven disc 4 .

[0021] There are at least two mounting holes 1-1.

[0022] Install the shock absorber on the flywheel. When the output torque of the engine or motor is small,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com