Automatic clamping device

A power and power shaft technology, applied in the field of automatic clamping devices, can solve the problems of unreliable grasping of materials by the manipulator, complicated production and processing, and long design cycle, etc., to achieve wide practicability and promotion value, low cost, and good maneuverability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

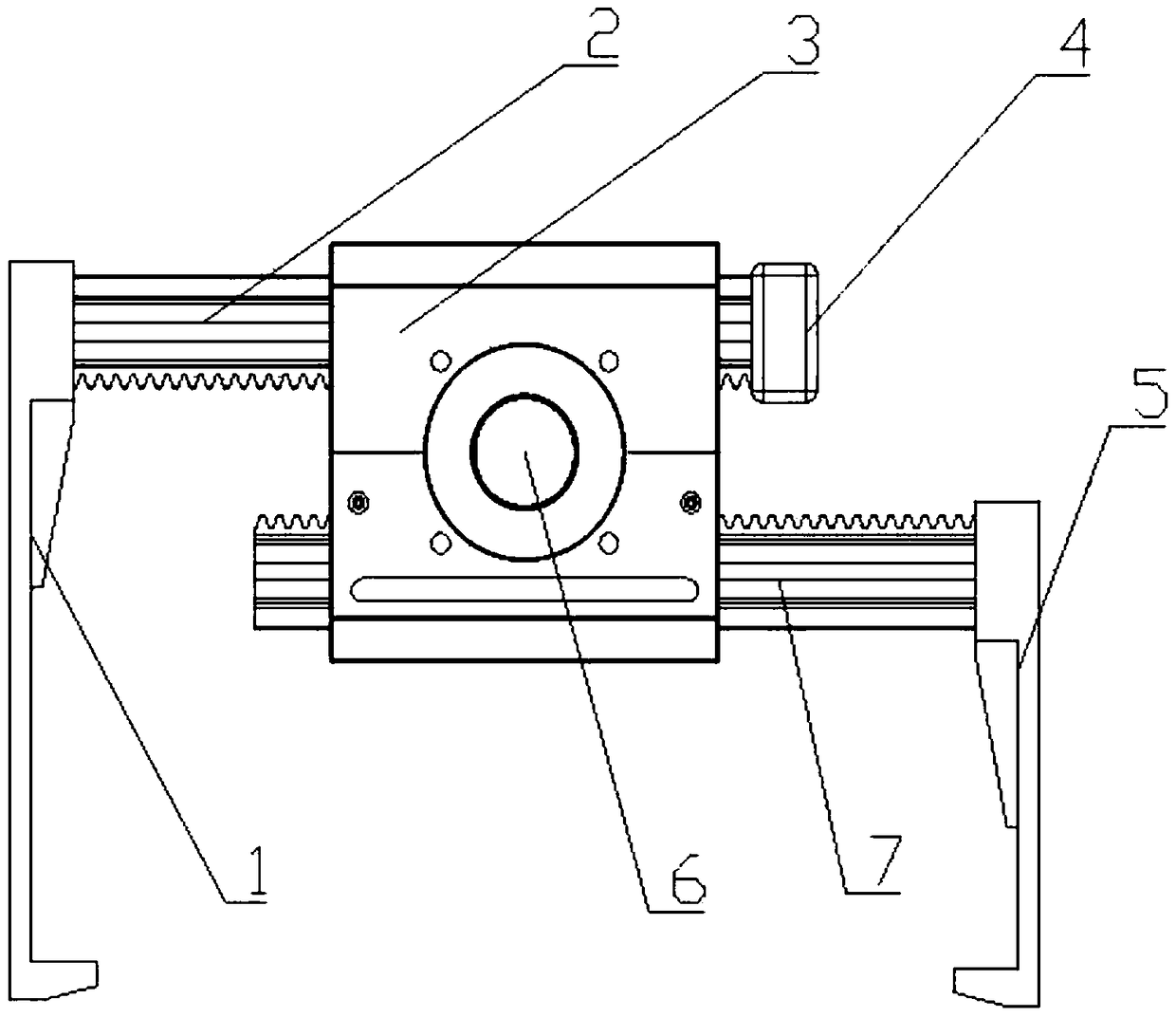

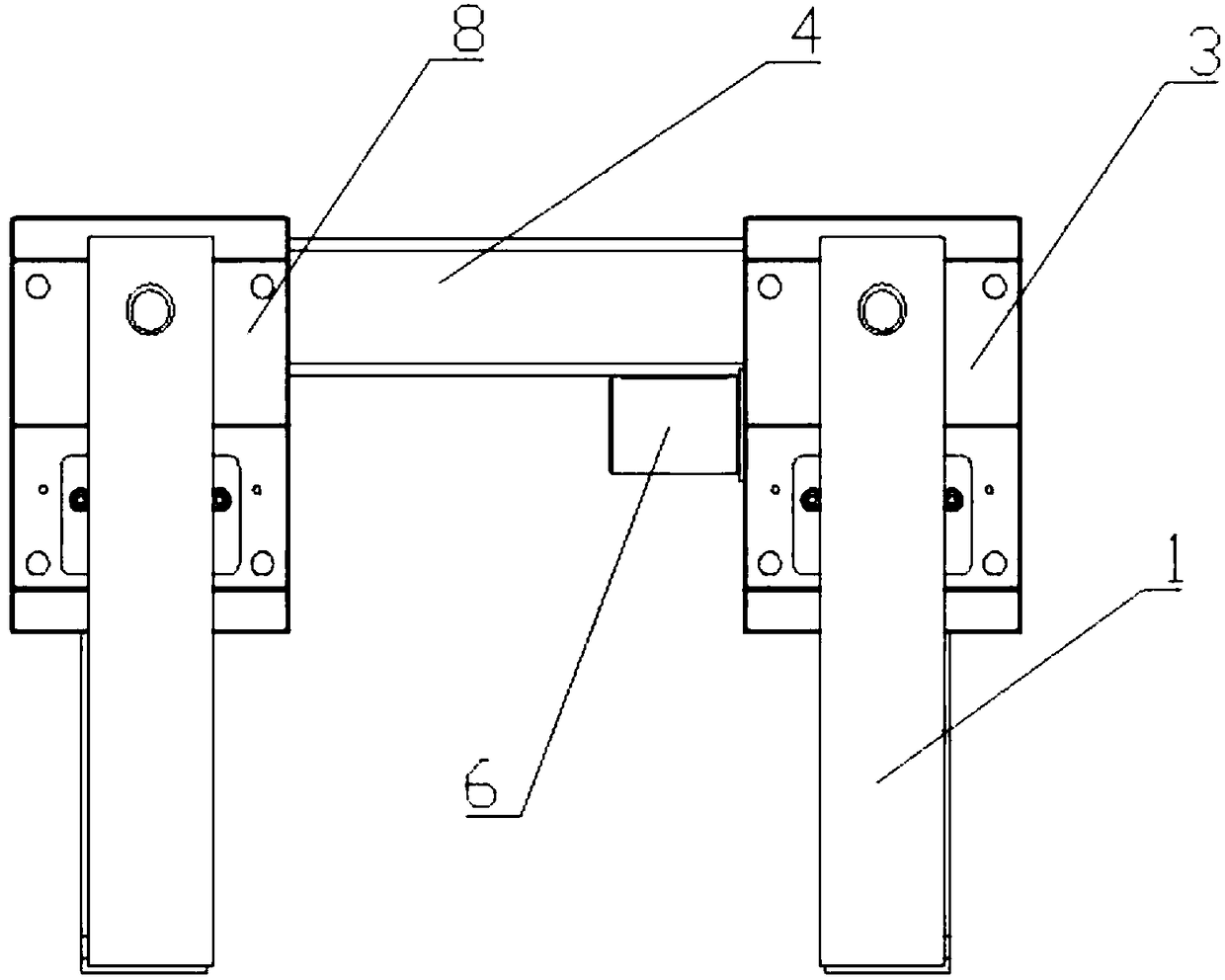

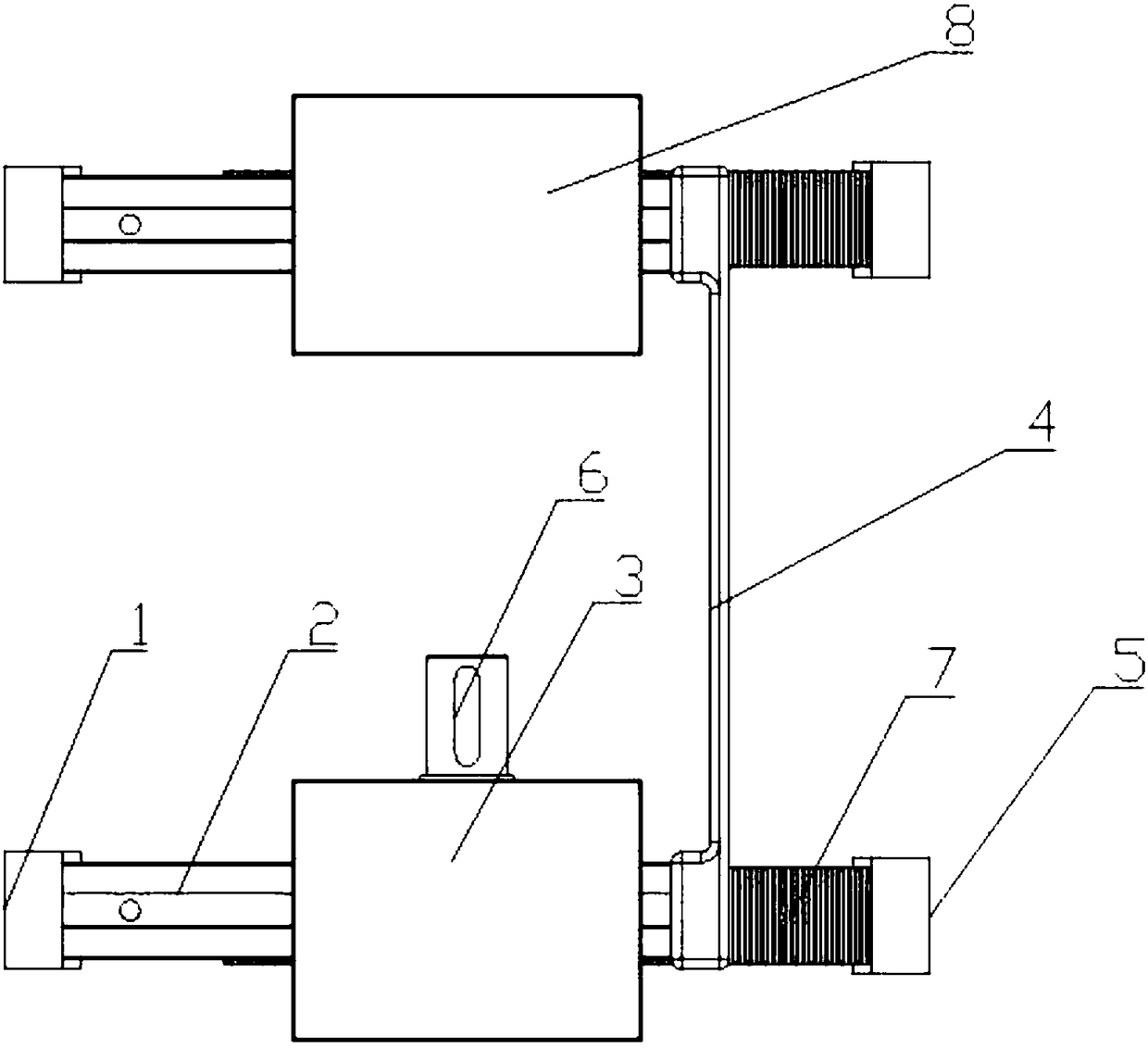

[0017] The present invention includes a power automation module 3, a driven automation module 8 and a connecting plate 4. The power automation module 3 includes a power shaft 6, a housing, a guide rail rack I2 and a guide rail rack II7, and two vertically opposite sides of the housing A mounting hole for the power shaft 6 is provided, bearings are arranged at both ends of the power shaft 6, and the bearings are installed on the power shaft mounting hole, one end of the power shaft 6 is arranged on the outside of the housing, and a There are gears, the guide rail rack I2 and the guide rail rack II7 vertically pass through the two vertical sides of the housing parallel to the power shaft 6, the tooth surfaces of the guide rail rack I2 and the guide rail rack II7 are opposite, and mesh with the gears respectively, and The forward direction of the two rail racks is opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com