Rotary kiln liner clearing robot based on electro-hydraulic servo proportional driving and control

A technology of electro-hydraulic servo and robot, applied in the field of machinery, to achieve the effect of flexible drive and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

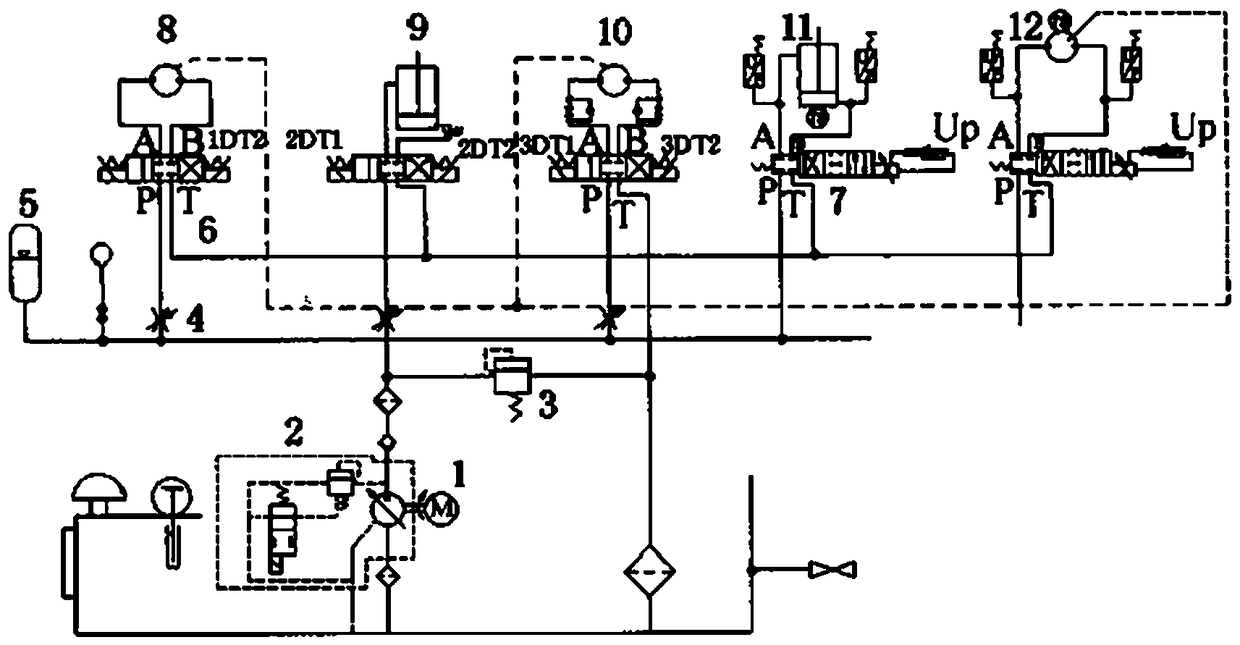

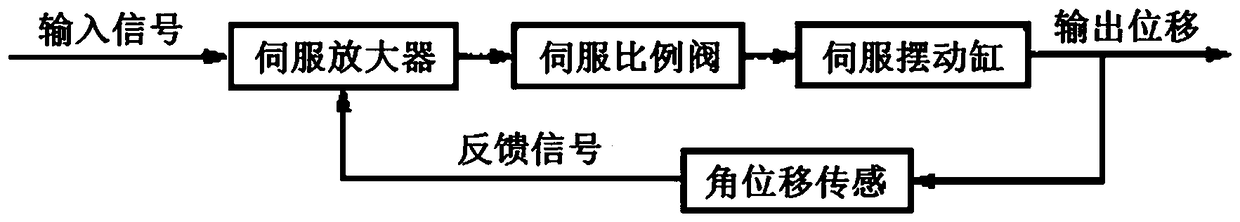

[0016] Such as figure 1 , the general hydraulic transmission system has the characteristics of cheap price, convenient adjustment and reliable operation, but it cannot achieve the output following the input and realize fast and proportional control. Therefore, some joints of the rotary kiln cleaning robot using hydraulic drive and control need to use general hydraulic transmission, while some joints need to use electro-hydraulic servo proportional technology to successfully complete the kiln lining cleaning operation.

[0017] It can be seen from the figure that the hydraulic system uses a variable pump to supply oil, its flow can be adjusted manually, and the maximum working pressure of the system can be adjusted through the relief valve. Electromagnetic reversing valve and travel switch are used to control the flow direction of hydraulic oil, so that the positive and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com