Pre-filter with automatic scraping and blowdown functions

A pre-filter, filter technology, applied in membrane filters, fixed filter cartridge filters, filtration and separation, etc., can solve the problems of inconvenience, waste of time and manpower, poor user experience, etc. Easy to wash, good use experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below with reference to the examples.

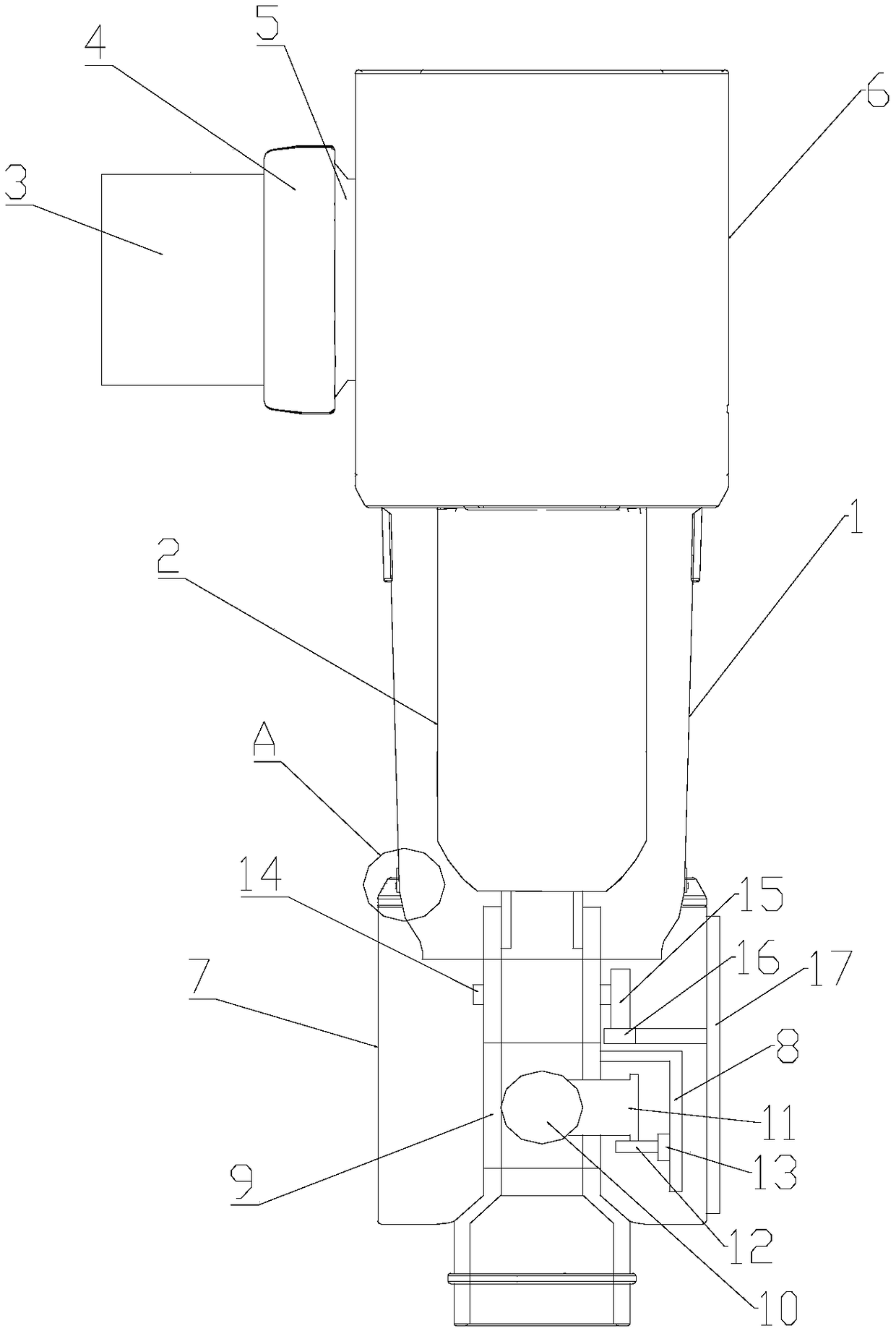

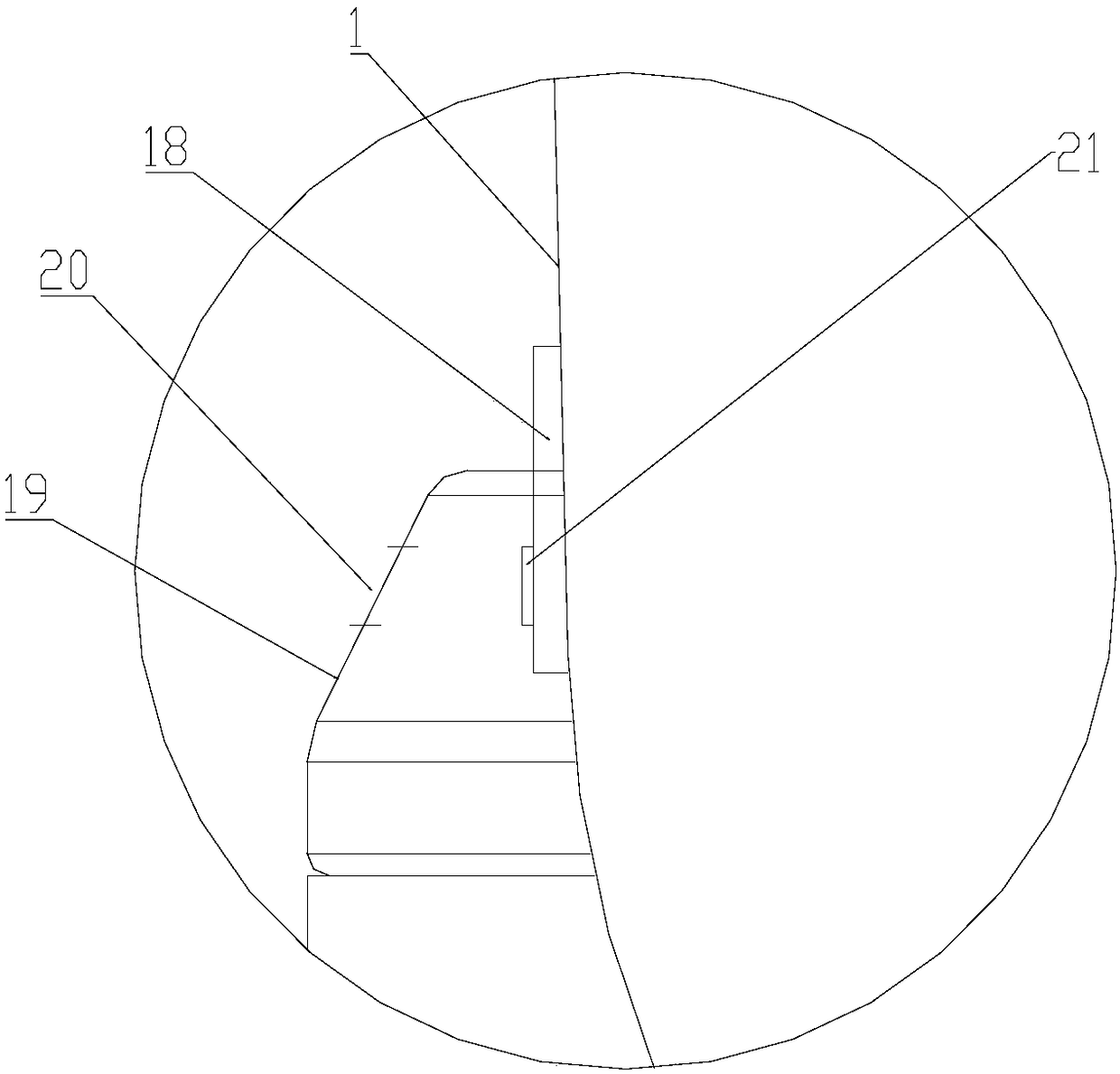

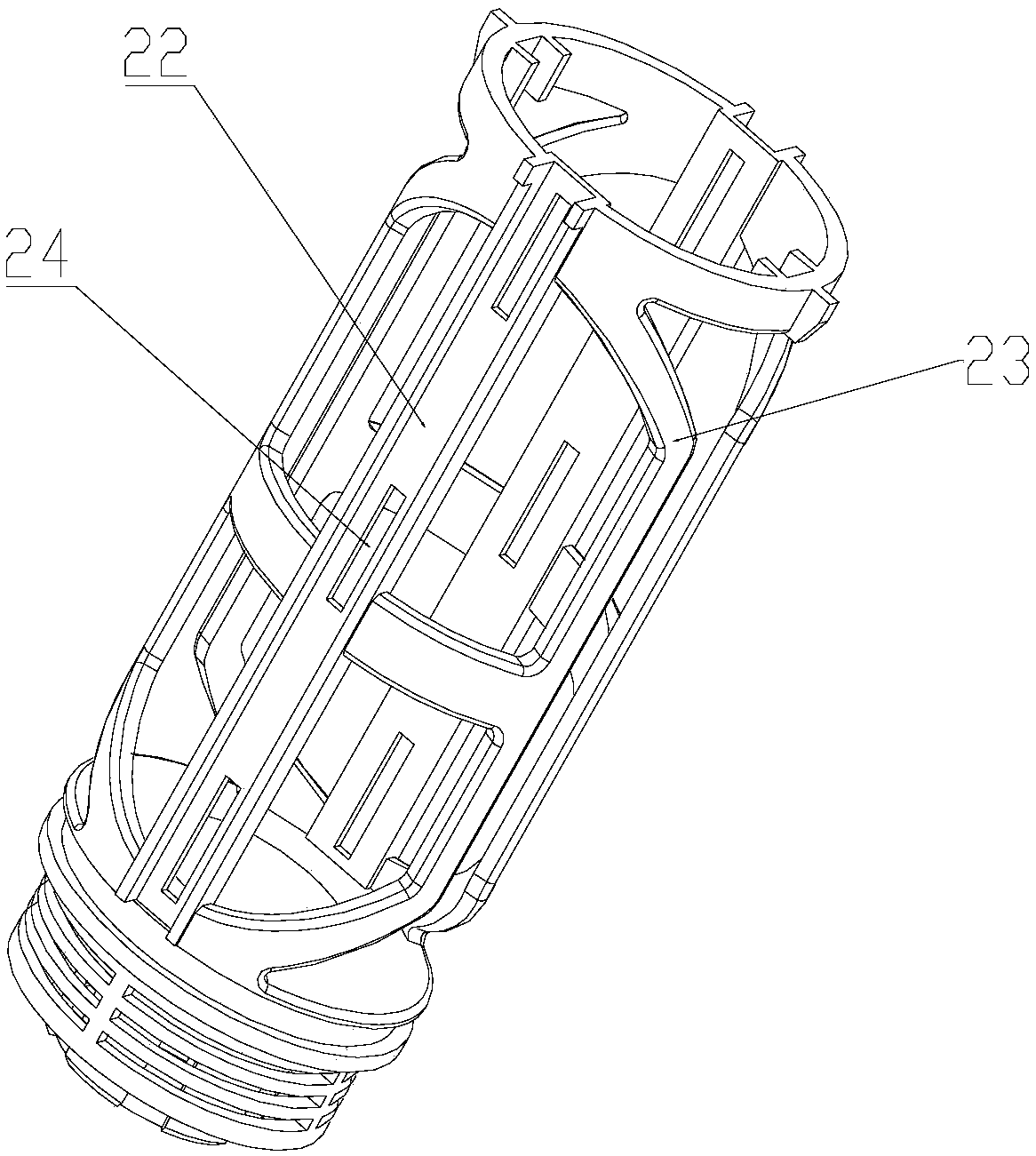

[0026] like Figure 1-4 As shown, the pre-filter with automatic scraping and sewage discharge functions includes a filter housing, a sewage outlet assembly is installed at the lower end of the filter housing and an outer casing that encapsulates the sewage outlet assembly, and the sewage outlet assembly is connected in the filter housing. The mesh skeleton 2.

[0027] The sewage outlet assembly includes a sewage pipe 9 and a ball valve for blocking or opening the sewage pipe. The copper piece 11 on the ball valve for rotating the valve core 10 extends out of the sewage pipe from the side wall of the sewage pipe, and the copper piece extends out of the sewage pipe. One end is in the shape of a turbine.

[0028] The outer casing includes an outer casing 7 and an inner casing 8, the outer casing is fixedly connected to the filter casing, and the inner casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com