Rotating electrical machine

A technology of rotating motors and rotating shafts, applied in electromechanical devices, electrical components, electric components, etc., can solve problems such as demagnetization of permanent magnets, deterioration of parts, etc., and achieve the effect of maintaining and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

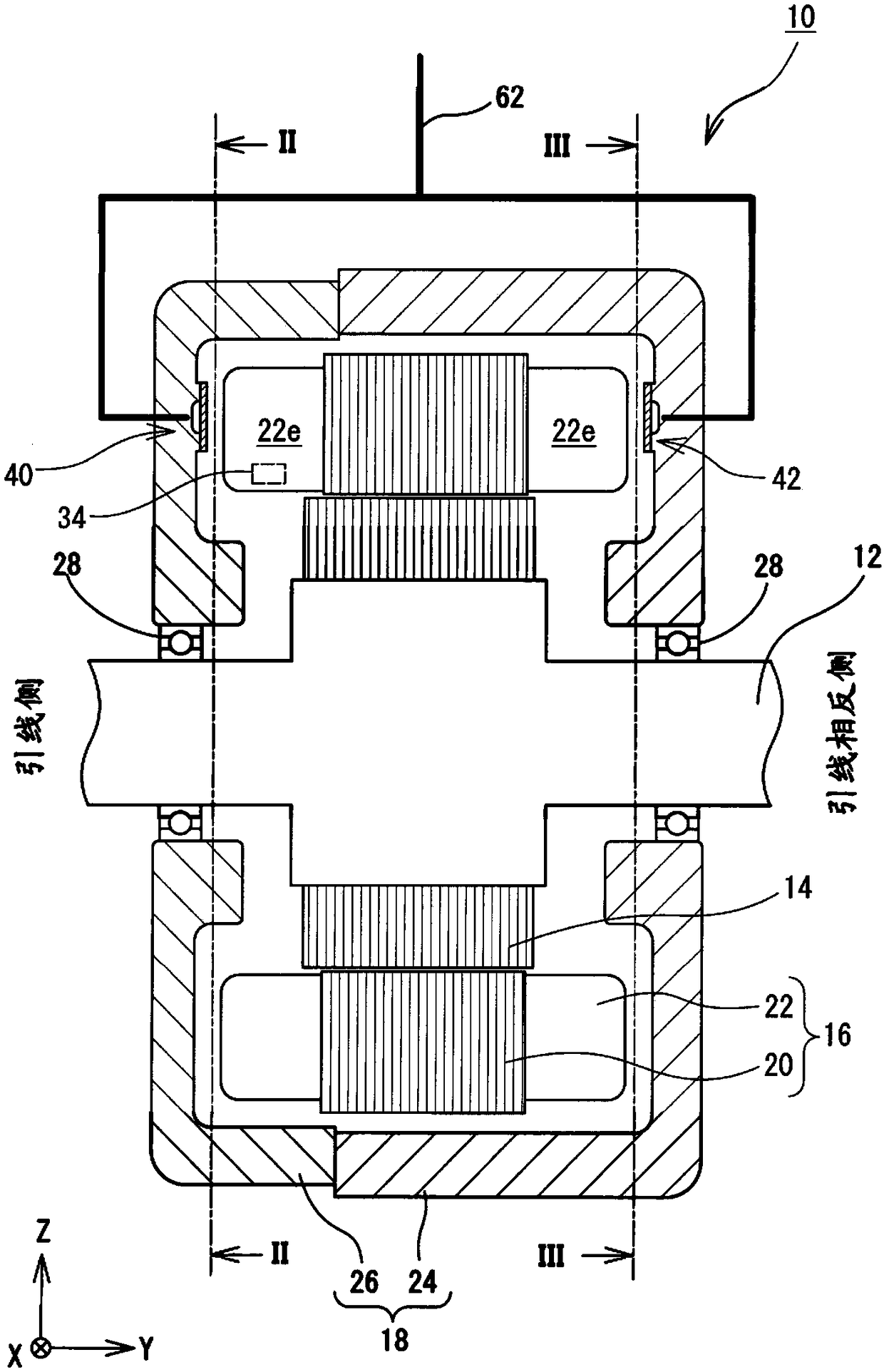

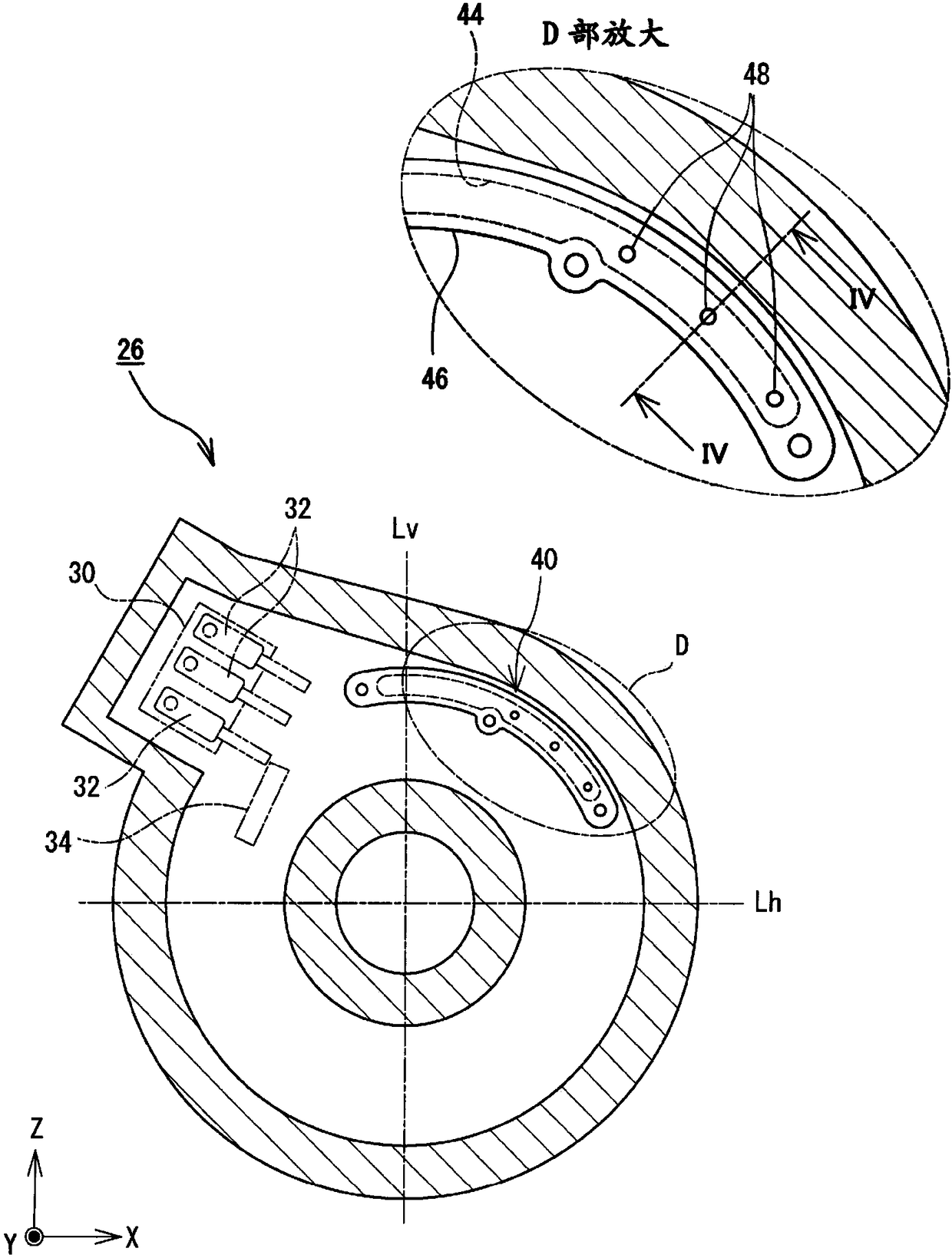

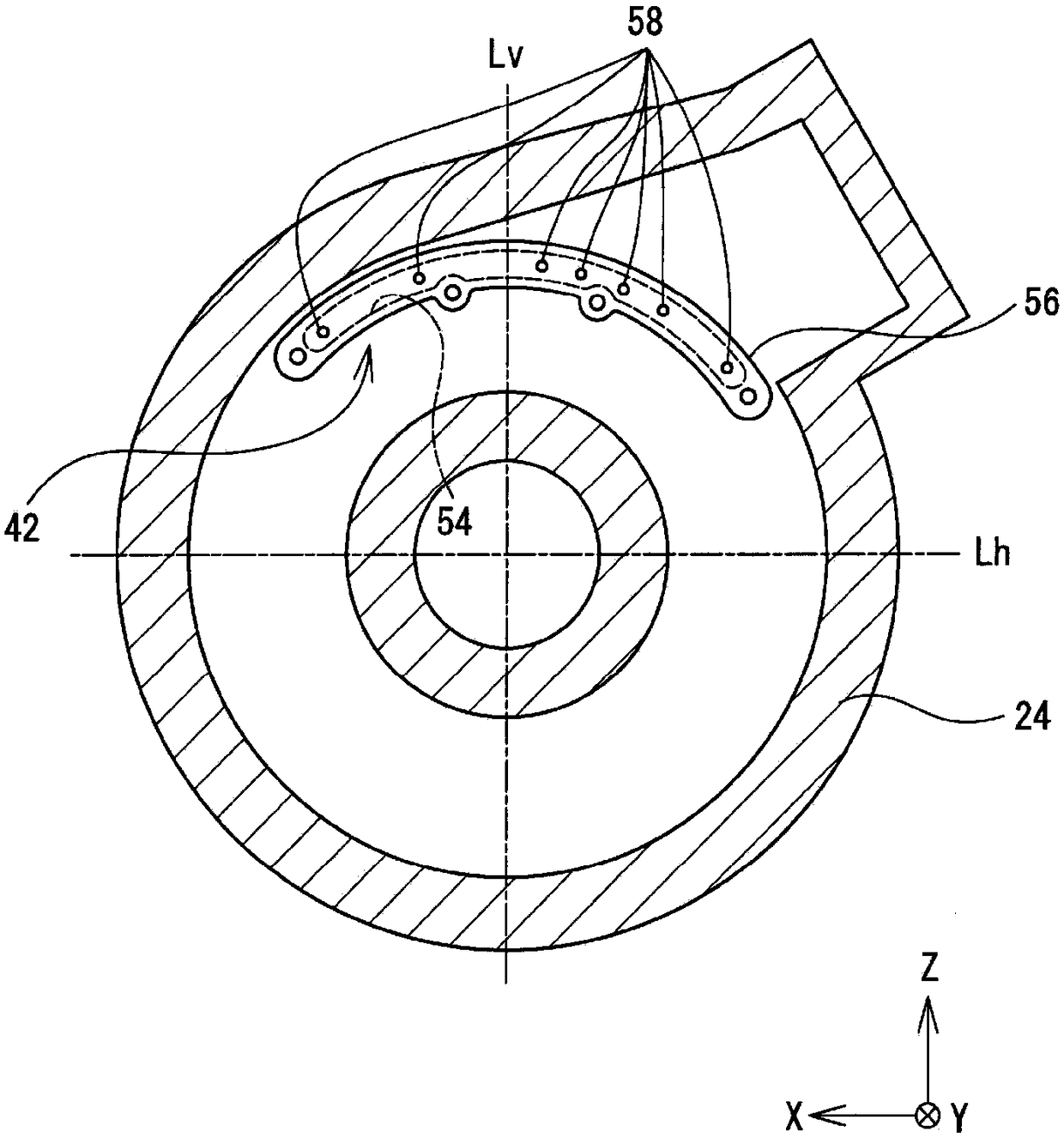

[0036] Hereinafter, a rotating electrical machine 10 as an embodiment will be described with reference to the drawings. figure 1 It is a schematic longitudinal sectional view of the rotating electric machine 10 as an embodiment. in addition, figure 2 yes figure 1 The II-II sectional view of image 3 yes figure 1 Sectional view of III-III. in addition, Figure 4 yes figure 2 Sectional view of IV-IV. In addition, in Figure 1 ~ Figure 3 , gravity acts from above to below the paper surface, the Z-axis direction is the gravity direction, and the X-axis and Y-axis directions are horizontal directions.

[0037] The rotating electric machine 10 described above is mounted on an electric vehicle such as a hybrid vehicle or an electric vehicle. In an electric vehicle, the rotating electrical machine 10 may be used as a running motor that generates power for running the vehicle, or as a generator that generates power by regenerative braking force or surplus power of an engine....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com