Method for improving ventilation precision of naesthesia machine through fuzzy pressure control

A technology of fuzzy control and anesthesia machine, applied in the direction of flow control, non-electric variable control, control/regulation system, etc., can solve problems such as too sparse gear position and subordinate relationship, control value not covered, overshoot, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

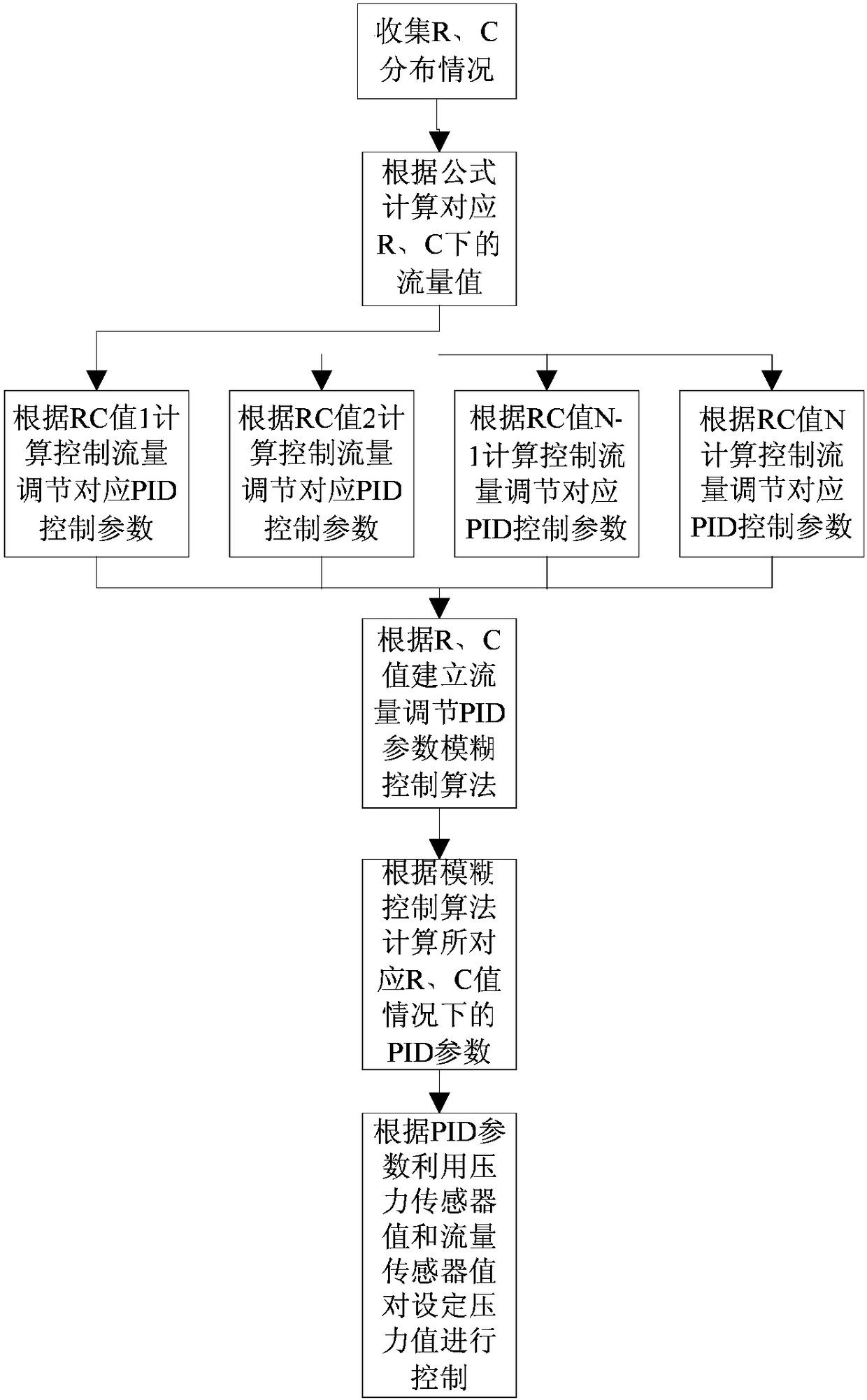

[0021] Such as figure 1 Shown, the control method of the present invention is as follows:

[0022] Within the value range of R=1~100cmH2O / L / s, C=1~100mL / cmH2O, according to the distribution data of R and C values of patients collected and collected in large quantities, select N R and C values with the highest occurrence probability as the positioning points, N greater than 10;

[0023] Adjust the PID control parameters corresponding to the N R and C values;

[0024] According to the characteristics of the PID control parameters corresponding to the N R and C values, a corresponding fuzzy control algorithm is worked out;

[0025] According to the formulated fuzzy control algorithm, calculate the PID control parameters corresponding to other R and C within the value range of R and C, and modify the fuzzy control algorithm to meet the needs of different R and C values;

[0026] After the control algorithm is corrected, the pressure sensor and flow sensor in the anesthesia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com