Buchholz indentation hardness tester

An indentation hardness and indentation technology, which is applied in the direction of testing material hardness, instruments, scientific instruments, etc., can solve the problems of inability to observe subtle changes, easy bending or wear, and horizontal damage on the upper surface to meet the requirements, Easy to operate, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

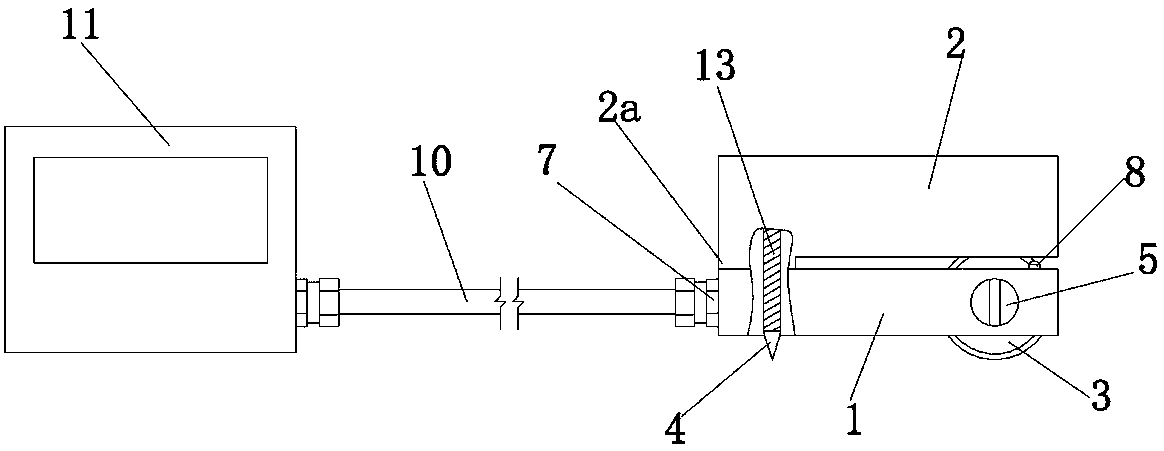

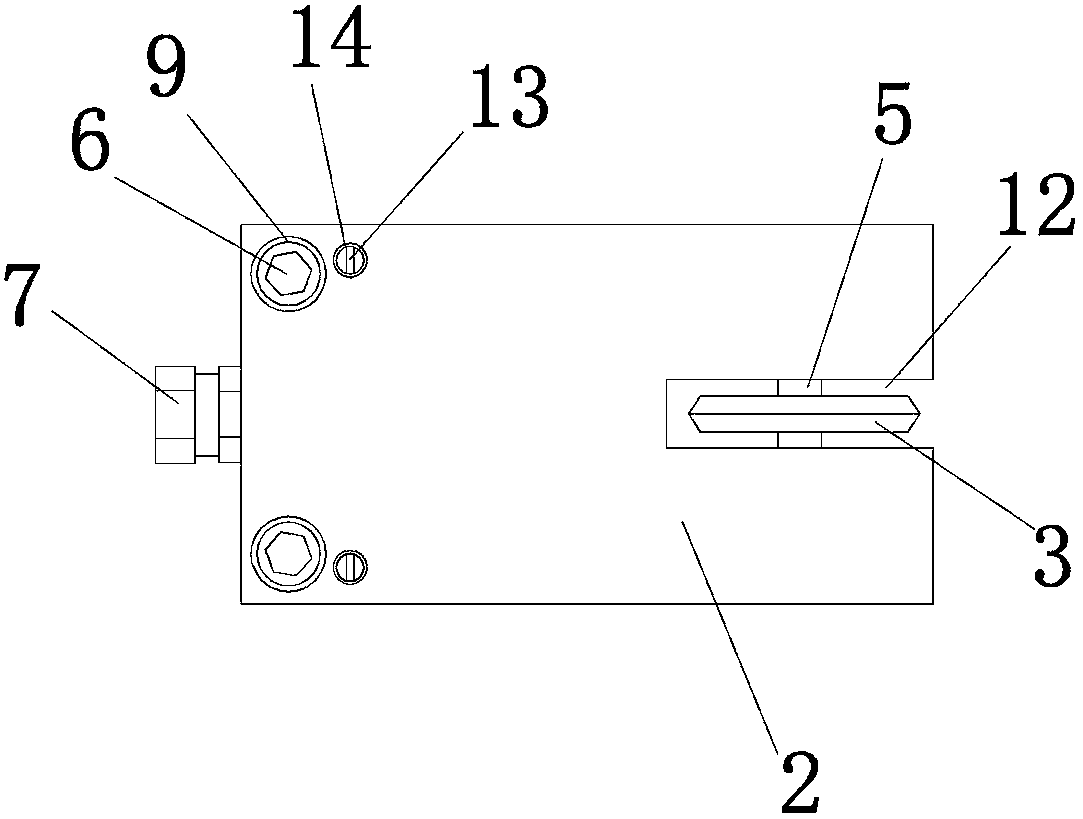

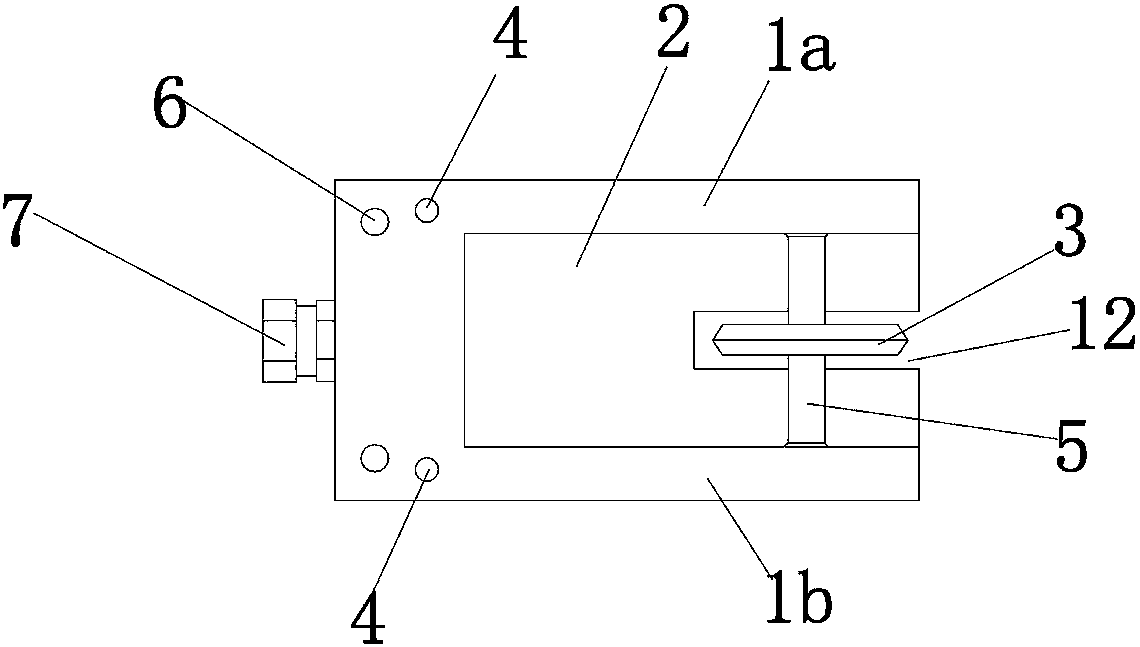

[0016] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0017] Depend on Figure 1-6 Given, the present invention includes a base 2 and an indentation wheel 3, a cantilever beam force sensor 1 is arranged below the base 2, one end of the base 2 is fixedly connected with one end of the cantilever beam force sensor 1, and the unconnected part of the base 2 It is arranged alternately with the cantilever beam force sensor 1, the indentation wheel 3 is mounted on the cantilever beam force sensor 1 away from the fixed connection end of the base 2 and the cantilever beam force sensor 1, and the lower end of the indentation wheel 3 protrudes from the lower end surface of the cantilever beam force sensor , the lower part of the fixed connection end of the base 2 and the cantilever beam force sensor 1 is connected with a pin 4 whose lower end extends out of the lower end face of the cantilever beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com