Seawater tank sealing test device

A sealing test, seawater tank technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of inconvenient operation, low efficiency, waste of materials, etc., and achieves detachable reuse, simple structure, improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

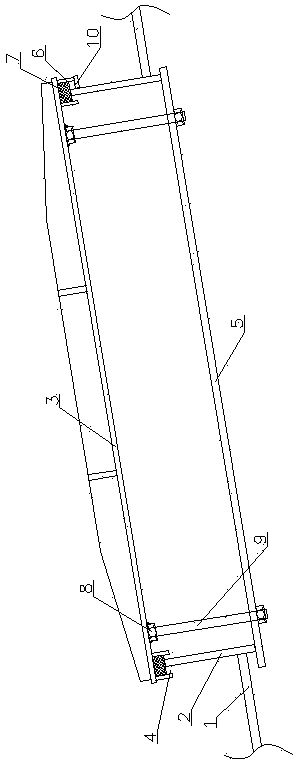

[0014] A sealing test device for a seawater tank, comprising a reinforcing ring 2 welded on the opening of the outer plate 1 of the seawater tank, the inner and outer ends of the reinforcing ring 2 exceed the two sides of the outer plate 1, and the inner end of the reinforcing ring 2 is provided with Sealing plate 3, a groove 4 is provided around the outer end surface of the sealing plate 3, the inner end of the reinforcing ring 3 is located in the groove 4, the outer end of the reinforcing ring 2 is provided with a pressing plate 5, and the pressing plate 5 Connect with the outer end surface of the sealing plate 3 by bolts.

[0015] As a further improvement of the above technical solution, the groove 4 is composed of two baffles 6 respectively located on the inner and outer sides of the reinforcement ring 2 , and the two baffles 6 are fixedly connected to the outer end surface of the sealing plate 3 .

[0016] As a further improvement of the above technical solution, a sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com