Full-automatic clothes cutting machine

A cutting machine, fully automatic technology, applied in the field of cutting machines, can solve the problems of large load of the rotating mechanism, reduced cutting speed, inability to automatically judge, etc., and achieve the effects of reducing friction, reducing error rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

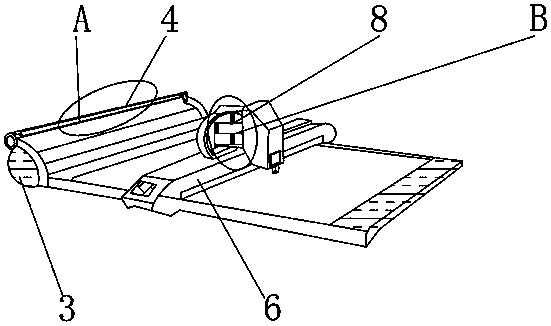

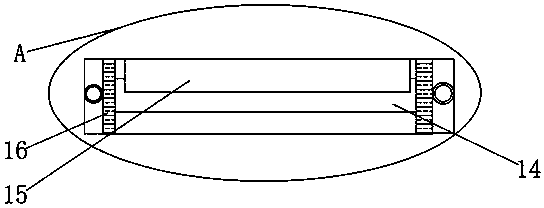

[0020] Such as Figure 1-4 As shown, a fully automatic garment cutting machine includes a cutting machine main body 1, a power switch 2 is arranged on the outer surface of the lower end of the cutting machine main body 1, and a drum 3 is fixedly installed on the front end of the cutting machine main body 1, and the upper end of the drum 3 is fixedly installed There is a pressing plate 4, and the two ends of the pressing plate 4 are provided with fixed knobs 5. Through the set pressing plate 4, it can ensure that the cloth entering the cutting machine is smooth and smooth, and the speed of cutting is improved. The upper surface of the main body of the cutting machine 1 is movable. frame 6, and one end of the mobile frame 6 is fixedly equipped with a control panel 7, the upper surface of the mobile frame 6 is movably mounted with a motor 8, and one end of the motor 8 is fixedly connected with a conveyor belt 9, and the lower end of the motor 8 is fixedly equipped with a cutter 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com