Method for disc loading of optical thin sheet devices

A technology for optical sheets and devices, applied in grinding devices, grinding machine tools, metal processing equipment, etc., can solve problems affecting processing quality, etc., and achieve the effect of saving raw material costs, overcoming unevenness, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

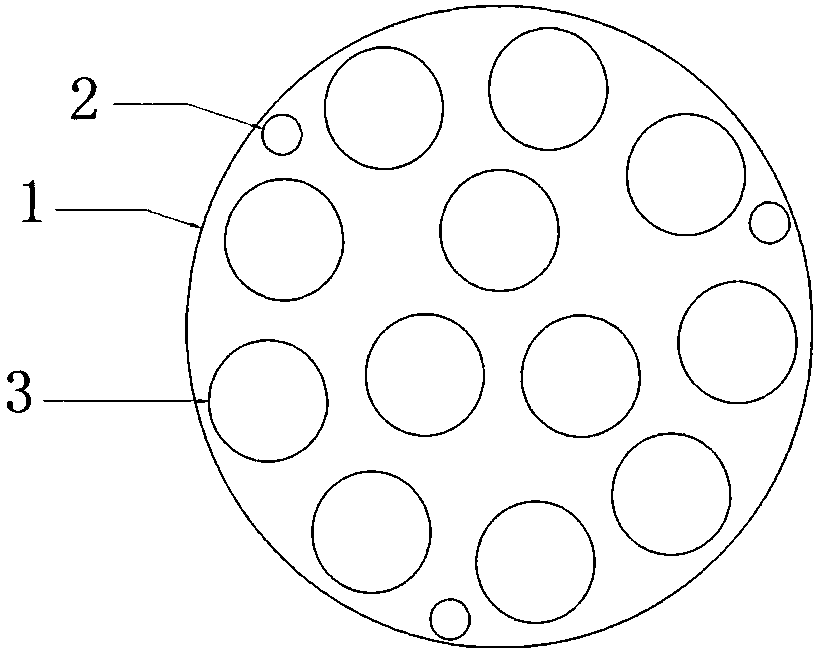

[0029] like figure 1 and figure 2 As shown, in the method for loading an optical thin film device provided in this embodiment, the size of the optical thin film device 3 is 30×1 mm, the quantity is 30, and the melting point of the low-temperature hot melt adhesive is 50 degrees Celsius. Firstly, make the frosted glass flat plate 1 to control its flatness within +0.002mm, and lay two layers of paper on the iron plate of the flat electric heater, so as to prevent the thin optical device 3 from directly contacting the heating plate, resulting in excessive temperature rise and large changes in the internal stress of the device. Spread 30 optical sheet devices 3 on the paper of the electric heater, and turn on the heating power. When the temperature of the optical sheet device 3 is heated to the melting point of the hot melt adhesive, the heating is stopped. Coat one layer of hot-melt adhesive with a thickness of about 1.5 mm on the optical sheet device 3 one by one, and an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com