A narrow gap laser-arc hybrid welding gas protection device and its adjustment method

A gas protection device and composite welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of melting, limited adjustable height, damage, etc., to ensure laminar flow effect, good protection, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

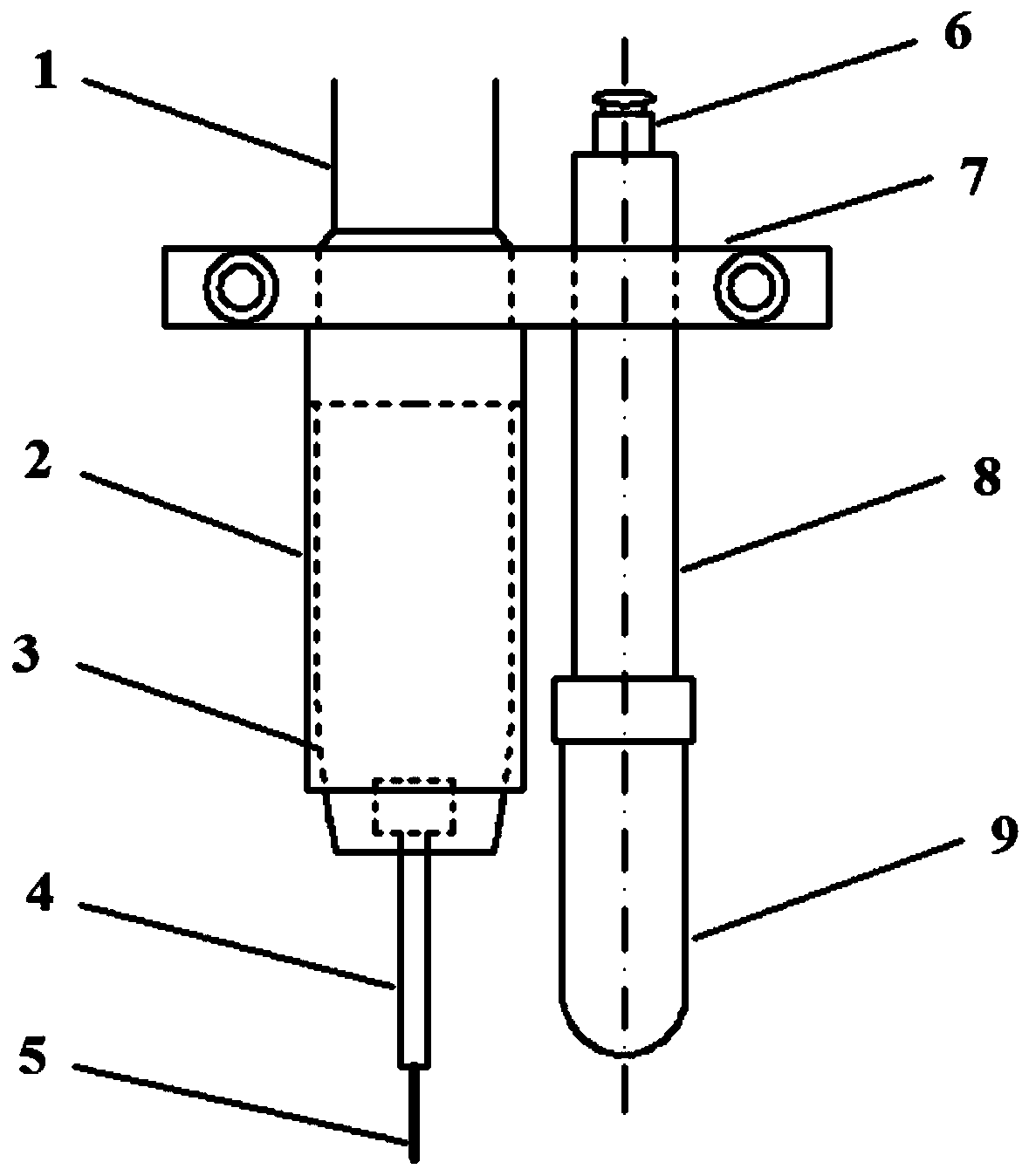

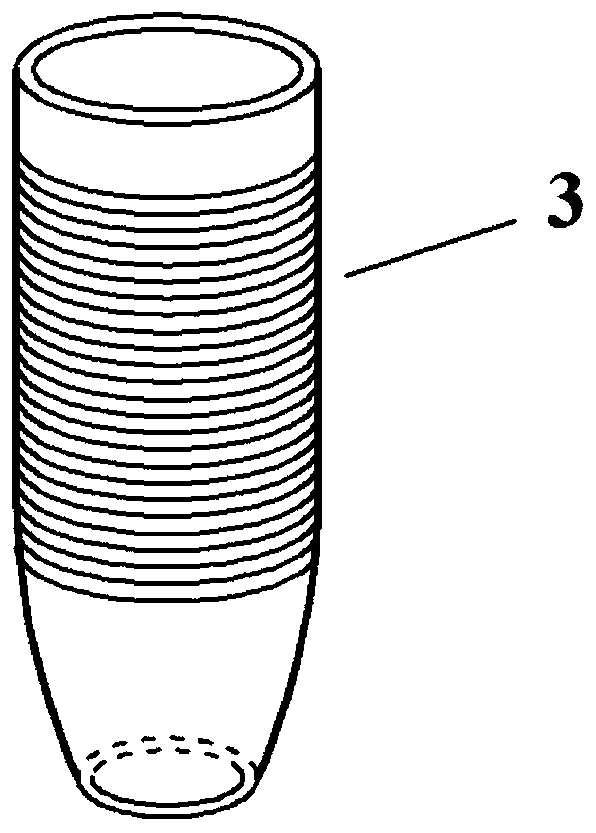

[0039] When the distance between the bottom of the groove or the surface of the weld and the upper surface of the workpiece 11 is t>30mm, it is suitable for Figure 5 situation shown. Install the rear auxiliary air flat nozzle assembly, including the quick insertion of the air guide tube 6, the clamping block 7, the auxiliary air connecting rod 8 and the rear auxiliary air flat nozzle 9. A separate protective gas inlet tube is used to connect the quick insertion of the airway tube 6. Rotate the main nozzle inner cylinder 3 (the main nozzle outer cylinder 2 does not shift), and at the same time move the auxiliary gas connecting rod 8 equipped with the rear auxiliary gas flat nozzle 9 along the direction parallel to the end of the welding wire 5, and the main nozzle assembly and the rear Set the auxiliary air flat nozzle assembly for coarse adjustment respectively. Adjust the welding torch 1 to the welding height along the z-axis direction, finely adjust the main nozzle inner ...

Embodiment 2

[0042] When the distance between the bottom of the groove or the surface of the weld and the upper surface of the workpiece 11 is t Figure 6 situation shown. At this time, the main nozzle assembly is fully capable of protecting the molten pool and cooling the welding wire. In order to avoid the risk of the rear auxiliary air flat nozzle 9 colliding with the side wall of the groove due to misoperation and to speed up the welding preparation work, the rear auxiliary nozzle 9 is removed. The air flat nozzle assembly includes the quick insertion of the air guide tube 6, the clamping block 7, the auxiliary air connecting rod 8 and the rear auxiliary air flat nozzle 9. Rotate the inner cylinder 3 of the main nozzle (the outer cylinder 2 of the main nozzle does not move), and make rough adjustments to the main nozzle assembly. Adjust the welding torch 1 to the welding height along the z-axis, and finely adjust the inner tube 3 of the main nozzle so that it is 2-5mm higher than the up...

Embodiment 3

[0045] When the distance from the bottom of the groove or the surface of the weld to the upper surface of the workpiece 11 is t=0, it is suitable for Figure 7 situation shown. Continue to rotate the inner cylinder 3 of the main nozzle (the outer cylinder 2 of the main nozzle does not shift), and make rough adjustments to the main nozzle assembly. Adjust the welding torch 1 to the welding height along the z-axis, and finely adjust the inner tube 3 of the main nozzle so that it is 2-5mm higher than the upper surface of the workpiece 11 .

[0046] When the distance between the bottom of the groove or the surface of the weld seam and the upper surface of the workpiece is t=0, the method described in this embodiment is used for welding. Since the protective gas blowing method of the main nozzle assembly is the same as that of the traditional fixed-length nozzle, the weld seam The shape is good, the surface of the weld is uniform, continuous, smooth and concave, and defects such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com