Gas-liquid separation equipment facilitating gas concentration testing

A gas-liquid separation and gas concentration technology, which is applied in separation methods, liquid degassing, and liquid degassing through filtration, can solve the problems of affecting the detection efficiency of gas concentration in liquids, cumbersome separation process, complex structure, etc., and is easy to realize , improve the filtration efficiency, and the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

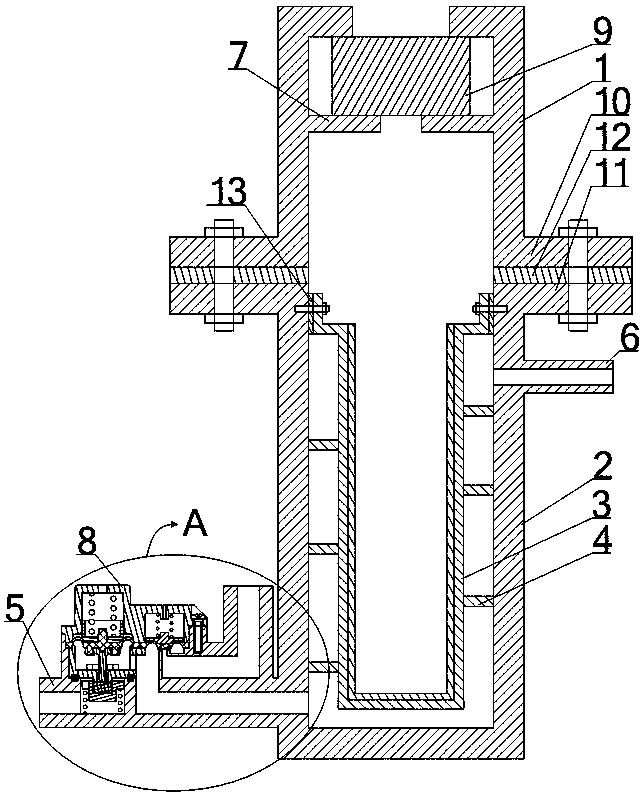

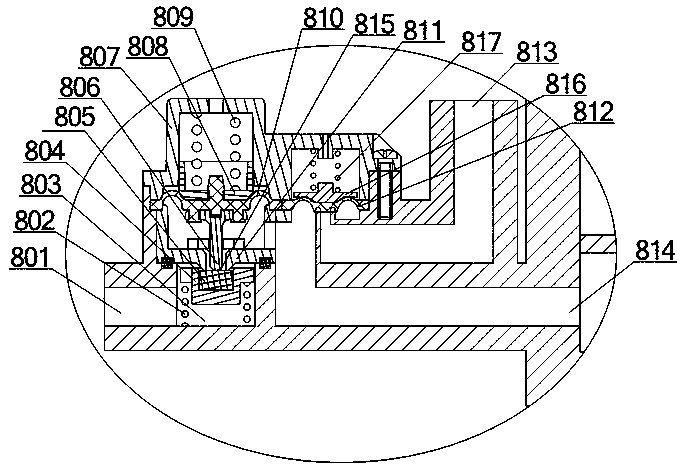

[0021] Such as figure 1 and figure 2 As shown, the gas-liquid separation equipment that is convenient for testing the gas concentration includes an upper shell 1, a lower shell 2 and a gas-liquid filter diaphragm 3, wherein the upper shell 1 forms a drum shape with an open lower end, and the lower shell 2 forms an upper end. Open barrel shape, the upper end of the lower housing 2 is sealed and connected with the lower end of the upper housing 1 , the gas-liquid filter membrane 3 is arranged in the lower housing 2 , and its upper end is sealed and connected with the inner wall of the lower housing 2 . A gas cavity is formed between the upper shell 1, the lower shell 2, and the gas-liquid filter diaphragm 3, and a transition chamber is formed between the lower shell 2 and the gas-liquid filter diaphragm 3. The upper and lower sides of the lower shell 2 A liquid outlet pipe 6 and a liquid inlet pipe 5 are respectively arranged on the wall, and both the liquid outlet pipe 6 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com